Good morning, I hope you are well, today I bring you something different than what I have already posted and it is about my work outside of music and how it came to me.

Always as a child I liked to watch others work as for example my father who is a tremendous industrial mechanic, I saw him and played with him to work with the tools filling me with grease and like every child make a mess in that area made me happy, and entering adolescence the stage where one wants to look nice, When I was between 14 and 15 years old I wanted to dress like a rapper and unfortunately here in Venezuela those clothes are expensive and my parents could not always please me until my father told me one day if you want your brand clothes work with me and with what you earn you can buy what you want.

That was how I with 15 years old I started working industrial mechanics specializing in the area of compressed air, one of the compressors that I started working were the Atlas Copco, on my way I had also started painting with compressor and I said to myself one day (I can grab that compressor and restore it completely) so that was how my father gave me my first project just to see how I was doing.

First project: Atlas Copco GA 115 Compressor

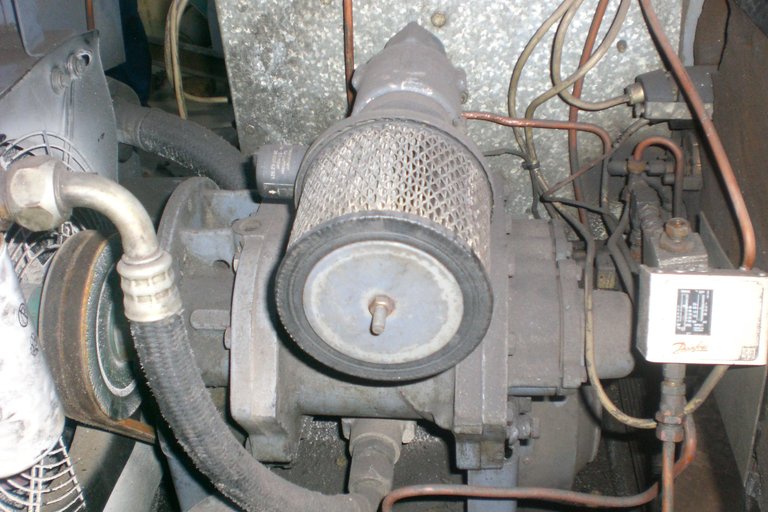

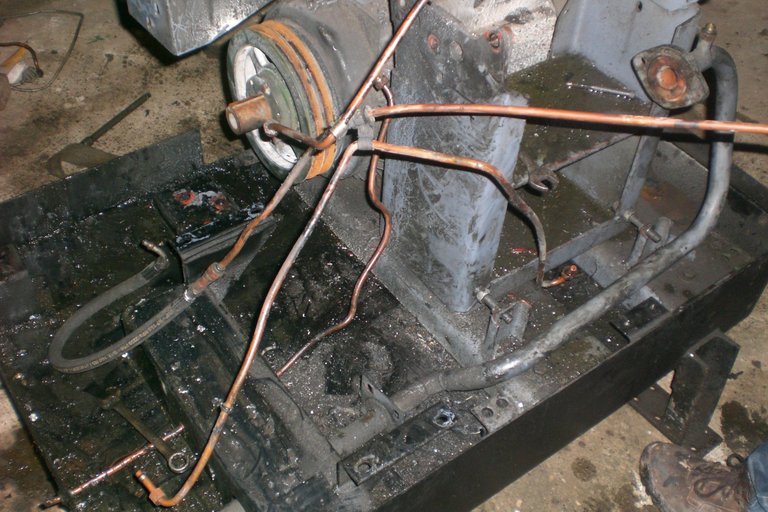

In this condition my father gave it to me, I felt confused, I didn't know where to start and well, like any apprentice, I started to disassemble and photograph step by step so that when I started to assemble it I wouldn't get complicated.

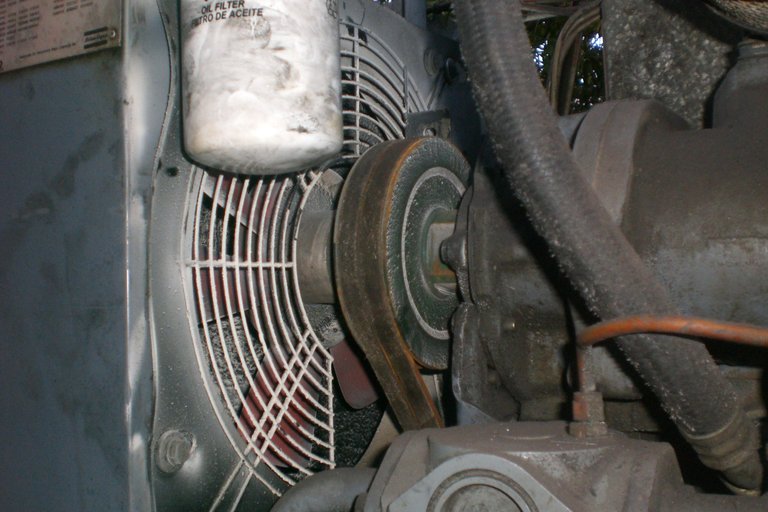

I started with the radiators and then went to the piping and wiring, also the separator tank and the scuba tank with the fan blade of the screw unit.

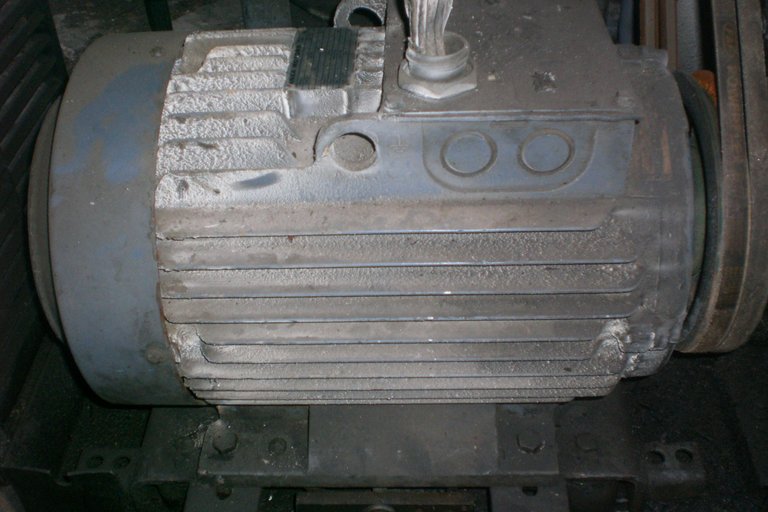

In this step I knocked down what would be the screw compressor unit and the motor with its base. Now only the pack or floor is left.

I proceeded to put all the compressor parts aside to select and wash them one by one, some with gasoline, soap and water and the radiators with their internal chemical bath.

After a long and hard day of work, here were the pieces clean, ready to start sanding and painting, unfortunately due to phone issues I had, at that time I lost the photos of the painting process, but soon I will upload more photos of other works where I restore as well.

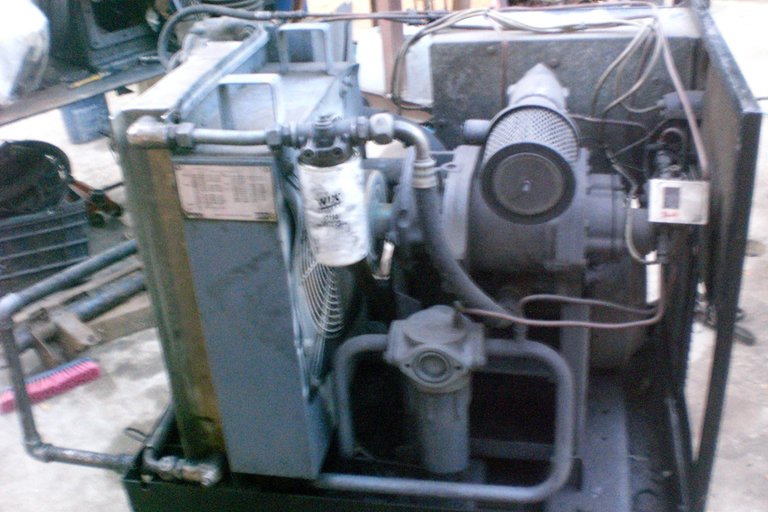

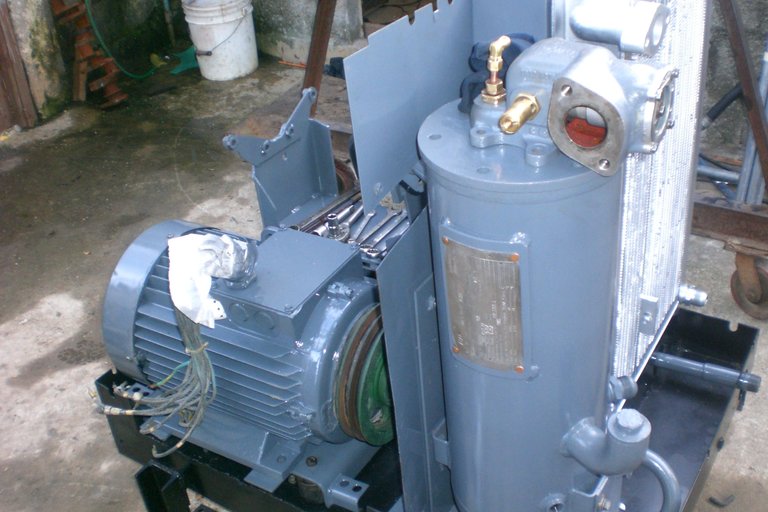

Once the GA 115 compressor parts were painted, I started assembling from the pack up, starting with the unit and motor bases, scuba and some piping next to the condensate trap.

Then put the compressor separator tank in place.

I had the compressor 95% ready, here I will show you how I was, although it lacks some parts such as hoses that by that time they were making new, as they were very toasted, did not give me a chance to photograph the complete end, the customer came for the compressor and I was not in the workshop my father made the delivery. The customer was happy because it seemed that it was not his compressor was fully restored by me.

I hope you like my work, I was very happy with it for being my first project, I thought I would not do it, but yes, I did it, I did it and it was beautiful, I like what I do, I like industrial mechanics, I would like through this community to have the support to buy more tools, because sometimes we do not have the resources to 100%. Soon I will be uploading more content of my work for you to enjoy. Blessings to all from this humble servant.

Hi @demianphoenix and welcome to Hivemotors, thanks for sharing your experience, it's good to have someone to share about industrial mechanics, I've seen dirty compressors but that radiator left me impressed, the restoration work was very good, congratulations to you and your father who is a good teacher.

Thank you very much brother, when we do the work with passion, everything will be almost perfect. I really like it and I hope to restore many more compressors .... Blessings my friend thank you

~~~ embed:1633166100388016131 twitter metadata:NzUzNDM3MjMzNzg1NTQwNjA4fHxodHRwczovL3R3aXR0ZXIuY29tLzc1MzQzNzIzMzc4NTU0MDYwOC9zdGF0dXMvMTYzMzE2NjEwMDM4ODAxNjEzMXw= ~~~

The rewards earned on this comment will go directly to the people( @josuerr29 ) sharing the post on Twitter as long as they are registered with @poshtoken. Sign up at https://hiveposh.com.

Congratulations @demianphoenix! You have completed the following achievement on the Hive blockchain And have been rewarded with New badge(s)

Your next target is to reach 50 replies.

Your next target is to reach 50 comments.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Check out our last posts:

Support the HiveBuzz project. Vote for our proposal!

Thanks friends, I hope to reach the finish line

Wow, two badges in a row, that's awesome @demianphoenix! 🎉

Looking forward to you reaching your new targets 😅

Hermano saludos que genial. Estas dejando ese compresor como de fabricase ve tan nuevo. La pintura le da nueva vida a todo jejeje Gracias por traer tu contenido a este lugar

Gracias hermano , si vale una restauración muy buena , lleva su trabajo pero vale la pena ver el resultado... Saludos amigo