Operation of any vehicle depends on the efficiency of all mechanisms. The ignition system is one of the important nodes. Owners of cars of domestic production are often faced with the problem of delay or advance its work. This failure may have several causes. This article describes how to configure early or late ignition, and that leads to this anomaly.

Operation of any vehicle depends on the efficiency of all mechanisms. The ignition system is one of the important nodes. Owners of cars of domestic production are often faced with the problem of delay or advance its work. This failure may have several causes. This article describes how to configure early or late ignition, and that leads to this anomaly.

The ignition timing

This, start the power unit. This is the desired period of time in which the spark lights the mixture charge. Determined by the special location of the knees of the shaft, when the candle arrives, the momentum of ignition relative to the top dead point, which is manifested in degrees. The ignition timing depends on the position of the piston. If ignition occurs in time at TDC, the fire will be only a little bit done during the quantum expansion, and the other part of the output. The piston is not getting the required pressure, and this reduces the usefulness of the whole function. Therefore, the time of placing the ignition needs to be set so that the pressure of gas affect VMT.

Pre-ignition gives the decline of the power of the engine. When the fuel ignites prematurely, it leads to the wrong action of the force of the gases, which occurs when combustion of the fuel. During load mode, when exposed to the best ignition angle it can cause an explosive ignition of the mixture. That it was not the lead angle you need to put a bit more in relative to this value.

Later ignition leads to unnecessary stress parts of the engine. Reduction of efficiency occurs because the fuel does not have time to fully burn in the gap when the piston is in TDC position. Workspace continues to burn as the piston moves down, which leads to a drop in performance and heating system.

Setting ignition timing

To adjust the ignition need to take a strobe light. If you don't have one, you can use a test light. The difference is that the device achieves the best precision calibers.

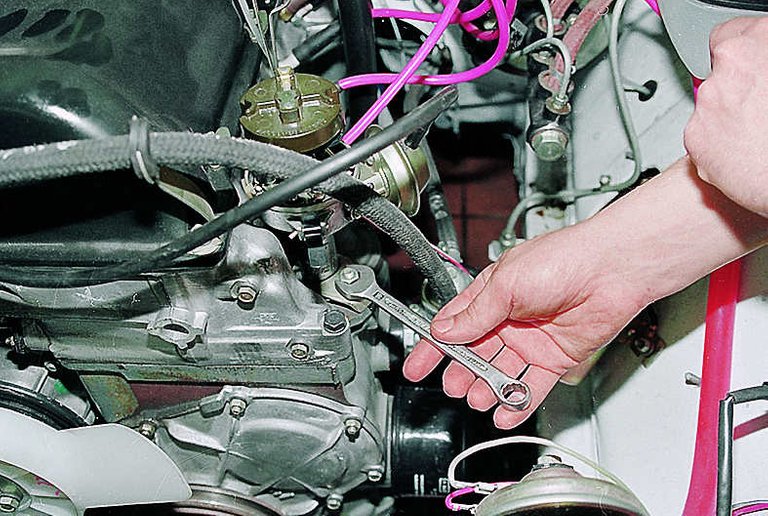

To start, Unscrew the bolt of the lock plate of the ignition timing.

Connect the device to the battery. Should to plus connect need a clamp strobe from the positive label, and ground connect to the negative terminal.

If the mechanism is the distributor vacuum control advance, you need to disconnect the vacuum hose.

The light from the fixture or light bulbs hover to the pulley.

Turn the machine on, and keep momentum in the area of nine per minute.

Strobe during use produces a light flash with a special speed, because of this you will see the mark on the pulley, it will be real.

Then expand the distributor housing so the mark on the pulley was on the same line with the middle division on the cover.

Now the fasteners can be tightened.

In the end the motor should run without interruption and explosions inside the cylinders.