In fact, this welding machine can be made, practically everyone who has two old microwave ovens.

To make this welding machine, you need the following tools and materials:

- Two transformers from the microwave. It is known, the transformer is one of the most important parts of the welding machine, it does not matter, contact, or electric arc apparatus.

- Electric drill, metal drill.

- The hammer.

- Saw on metal and canvas.

- Electra wire stranded section of 10-13 meters. The rigidity of the wire is limiting to work.

And so we, prepared all the necessary parts and tools for the work, you can begin to manufacture this unit.

First of all, you need to disassemble the microwave. We disassemble extremely accurately, without having damaged a trance.

- Transformers, should be securely fastened, so that they would be in an immobilized state.

- It is important! It is necessary to remove the secondary winding of transformers without damaging the primary one, thereby leaving the windings at 220 volts.

- It should, reduce the voltage of metal, drill it.

- Knock out the current shunts, if any, in order to increase power.

- Next, you should make a homemade winding, from our stranded wire, thereby connecting both transformers.

It is important! Pay attention to the quality of the winding, when applied. Namely, it should not be weak and in any case should not hang out. The winding should be tight, while lying exactly round to the coil.

- Connect the windings should be parallel and, accordingly, reliably isolate everything. You need to take a responsible approach to the isolation process, as this is a matter of your personal safety.

- It is necessary to measure the voltage of the secondary winding by connecting all the resulting structure to the power supply. The voltage should be from 30-33 volts.

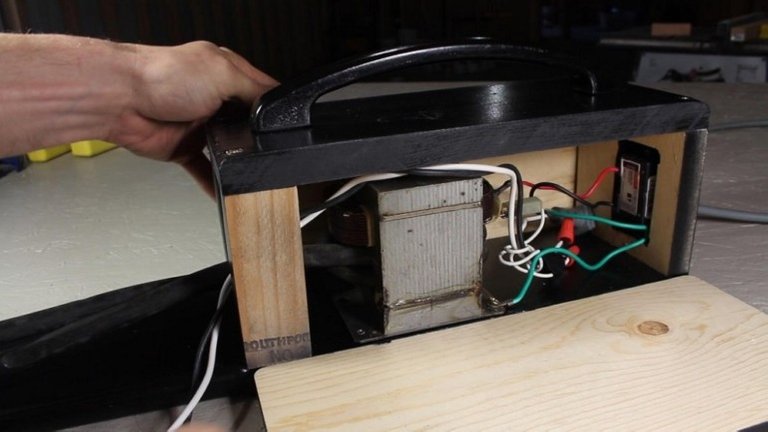

- Now we need to fix our entire structure so that it is neat and compact. As a pallet, you can use a small sheet of metal and a board.

- The last step in the manufacture of the welding machine will be the holder for the electrode, you can use the usual pliers or any other crocodile clips.

Further, after complete assembly of this unit, you can check it in action. A device of this kind is not suitable for too long work and for work on too thick metal, just as transformers need rest. It is advisable to avoid strong heat in order to avoid damage to the winding. It is recommended to let the welding machine cool down after one or two produced electrodes, in general, the more often, the better. Rest will contribute to a longer life of your welding machine.

For the production of this unit, of course not suitable, but in household needs, it will come down and help. Considering that manufacturing does not require expensive parts and special skills for assembly, this device is quite relevant in everyday life.