Maple Syrup is sweet syrup made from the sap of maple trees, particularly from sugar maple, red maple or black maple trees. It was first collected and used by Indigenous people of North America and with time it got much easier to make the syrup but I hope the sweetness remained the same. Currently, Quebec in Canada and Vermont in the United States are the largest producer of maple syrup.

I am from Canada and maple trees are in abundance here and it’s a national tree of Canada. This being the season of maple we went to a maple syrup festival in Ontario. It was a cold day yesterday but many people had come out to enjoy the festival, which generally lasts for 4-6 weeks. There we saw and learned how maple syrup was made in past and present, and it was very interesting so I decided to share it with everyone.

The production of maple starts naturally. Maple trees have sap, which goes down to the roots during late fall, as sap is what helps in growth of the tree, it is important that it doesn’t freeze. So at the onset of the spring, due to warmer weather during the day, the sap starts traveling up the trunk. And when it gets colder it runs down the root. Hence the sap goes up and down the trunk in 2-3 months window. It might not run up and down every day, the nights have to be colder than days for the process to happen.

Indigenous tribes of North America first made maple syrup and maple sugar.

- They made incisions in the bark and collected the sap.

- Then started a fire from the collected wood and heated stones in the fire.

- Once the stones were hot enough, they used V-shaped branches or antlers to pick and put them in the sap, which made the water evaporate and what would remain was maple syrup.

Fun fact- It took them around 7 days to make the syrup.

But how would they store the syrup for the summer months, as there were no refrigerators. For that, they converted syrup into crystallized sugar by continuing the same process with the hot stones. And that way they could use the maple syrup or sugar throughout the year.

Then entered European colonists and the Indigenous people showed them how to harvest the sap and produce syrup. European settlers and traders by 1680 started producing the maple products.

- Instead of making an incision in the bark, they started drilling tap holes in the trunk.

- They started making couple holes in one tree, inserting a tap and a bucket to collect the sap.

- Then they used large metal vessels to boil the syrup till the desired consistency was achieved, this was the most time-consuming process.

With the change in time and technology, today the process of making has become simpler but still it is time-consuming. These days instead of hanging buckets for harvesting, plastic tubes are attached for taping out and for sap collection. The tubes run to the sugar shack (where syrup is made).

Fun fact- Maple syrup tastes different depending on the time of harvest, syrup made from initial harvest is lighter and eventually keeps getting darker.

So this is how it works-

- First, the sap runs through the pipes, which are attached to the

trunk of the trees. - The sap is collected in a tank to which a pipe is attached, that carries the sap down to the evaporator.

- In the evaporator, there are grooved pans through which the liquid flows and due to heat, the water starts evaporating, making the syrup thicker and thicker.

- The pans are leveled, which makes the flow of the syrup easier. And the final channels are where the gradual color change can be seen, as it becomes syrup.

- To make the syrup thicker, the syrup is then boiled on the stove manually or sometimes there is another open pan attached to the evaporator wherein with the gradual heat, the syrup starts getting denser and sweeter.

- And finally, it gets bottled and sealed.

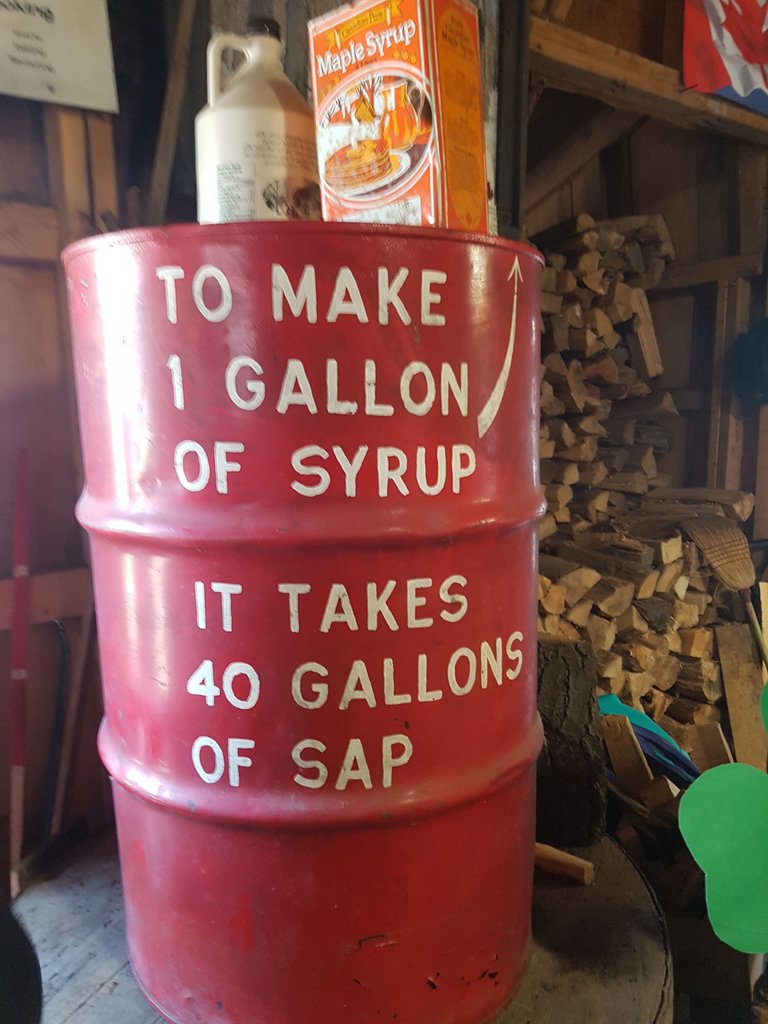

Fun fact- It takes 40 gallons of sap to make 1 gallon of syrup!

Now there are many maple products like maple butter, taffy, sugar and some places are even selling the maple sap water.

Maple syrup is a good alternative for white or brown sugar. It has antioxidants, high levels of zinc and manganese, which keeps heart healthy and boosts the immune system.

The tour ended on a sweet note, they gave us a shot of hot and fresh maple syrup from the evaporator and also maple syrup ice candies…unfortunately, I can’t share those with you all.

Informative and interesting. like you photos.