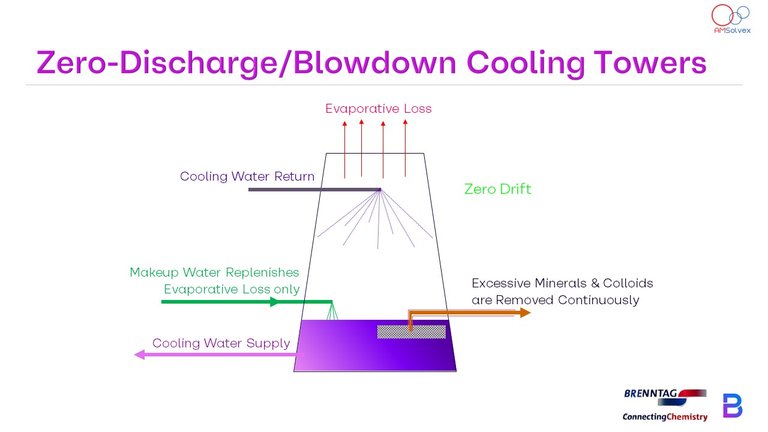

Recirculating Cooling Water in Evaporative Cooling Systems gets more and more concentrated with minerals and various substances that can get into the Cooling Systems (colloids, microorganisms and etc.) over time due to constant water evaporation. Therefore, Cooling Towers (and Evaporative Cooling Systems in general) need to discharge/blowdown some of its recirculating water and replenish with fresh makeup water to makeup for evaporative loss, drift loss and diluting down the Recirculating Water to prevent/reduce scaling.

Cooling Towers blowdown/discharge is a significant water wastage if the discharged stream is not redirected for other usage (i.e. landscape irrigation etc). Very often, it is not feasible or enticing to reuse discharged water from Cooling Towers as they contain residual biocides and other toxic substances (i.e. certain descalants, antiscalants and corrosion inhibitors etc.) which needs to removed or detoxified before redirecting for secondary usage.

Zero Discharge/Blowdown Cooling Towers are gaining more popularity as corporates are paying more attention to water conservation. The most common way to realise Zero Discharge/Blowdown Cooling Tower is to remove minerals and colloids (and whatever substances that reduce Cooling Systems' efficiency) in Recirculating Cooling Water continuously by Adsorbers of some sort (by mechanisms such as Capacitive Deionization, Electrolysis, Ion Exchange, Osmosis and etc.) to maintain the Total Dissolved Solids (TDS) at non-scaling level. One issue that needs to be addressed for this type of system is whether the adsorber can selectively remove undesirable minerals and colloids while sparing the active antiscalants, corrosion inhibitors and biocides intact.