Cationic Starch has two jobs to do in the wet end system.

- It is used to emulsify ASA or AKD (Alkaline sizing)

- It is used to improve fiber to fiber bonding

- Better internal bond

- Better tensile

- Improve burst

How does it work?

Fiber in the wet end is anionic (-) or negative charged.

Solsacat is attracted to the fiber and thus can help bond fibers together.

How does it work with ASA and AKD?

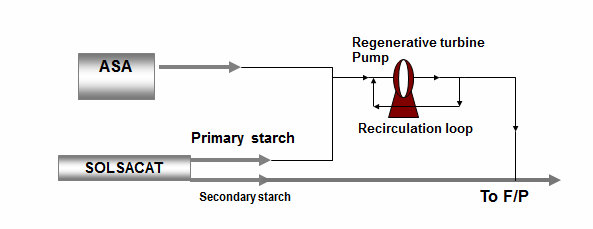

Cationic starch mixed with either ASA or AKD size under precise conditions by the sizing supplier.

The Cationic starch then provides a liquid layer around the sizing that “sticks” it to fiber. The cationic (+) charge is the main mechanism.

The starch protects the sizing chemical from other chemicals when wet and flows away when in the dryers

Basic laboratory emulsification test

•Emulsion stability vs time

•Starch concentration variation

•ASA : starch mixing ratio

•Water quality effect (hardness)

• ASA dosage variation

Conclusion

• ASA emulsion should be directly dosed to the machine without storage

• Starch concentration should be kept @ 4 % solids

• The emulsification ratio of ASA : Starch should be 0.5 – 1.0 : 1.0

• The emulsion particle size should be in the range of 0.5 – 1.5 micron and pH should be between 3.5 – 4.5