The world’s first rocket and space technology to produce fuel by using fuel oil residues from refineries offered by Anatoly Papusha, the Academician of the Russian Academy of Natural Sciences who developed the Buran program Papusha Rocket ICO - is the latest technology to destroy oil refineries residues around the world. Instead of destroying flora and fauna, refineries get gasoline and diesel fuel for selling.

PROBLEMS IN THE MARKET

The common goal is to maintain and improve the ecological situation all over the world for us and our children.

All countries of the world that have refineries (oil refineries) face the same unsolvable problem – storage and utilization of oil refinery residues. When processing modern high-gravity oil grades, the share of residues reaches a high value, about 10-20%.

Oil refineries are surrounded by storages and lakes with useless black mass which pollute the planet. Such use of "black gold" is unacceptable.Such use of "black gold" is unacceptable. This will lead to the ecological disaster for the next 100 years.

- High cost (tens of millions of dollars)

- Low efficiency

- Difficulty in operation and maintenance

- Long payback period

SOLUTION

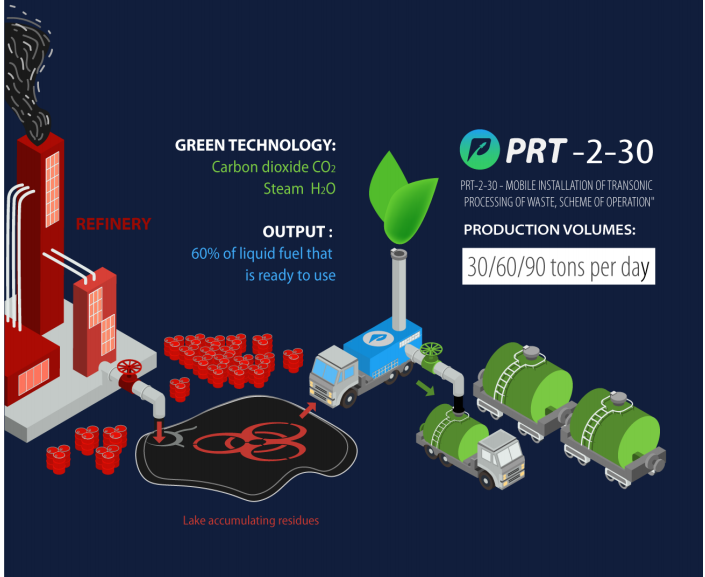

The technology of transonic combustion to eliminate super toxic residues developed by A.I.Papusha is applied in oil refining: due to minor improvements, the innovative unit can do something that was previously impossible – to extract such demanded products as gasoline, kerosene, diesel fuel, and synthetic oil, which is extremely valuable from practically unused oil production residues

.

PRT unit developed by Academician Papusha

- Small dimensions

- Low cost of creation and operation

- Equipment reliability

- High efficiency and quick payback period

- Universality and autonomy

Small-sized PRT-2 units allow the output of up to 60% of liquid fuel. There are no analogues of PRT-2 in the world. Several large oil refineries are very interested in buying it.

HOW DOES IT WORK?

- Oil processing generates a lot of residues, which are of little use and are a threat to the ecology of the entire planet. Oil refineries (refineries) pour residues into special containers or in so-called “storage ponds”. Thus, they greatly damage the environment and deprive themselves of potential profit from their processing.

- Small-sized PRT-2 processing unit uses the contents of such ponds as raw materials. Oil residues are processed at high temperature (more than 1,000 0 С) at transonic speeds (~1,000 m/sec) by adding special impurities. Under such conditions, the processed substances undergo radical physico-chemical changes, most of which turn into synthetic gas. Further, the substance enters the cooling unit, where a useful product is synthesized (kerosene, gasoline, oil, etc.). In this case harmless water vapor and carbon dioxide are delineated into the atmosphere.

- The valuable raw materials obtained in an environmentally friendly manner are accumulated in special tanks that are ready for further transportation and sale.

ADVANTAGES OF USING SMALL-SIZED PRT-2 FOR OIL PRODUCING COUNTIRES

- Liquid products from practically unused raw materials,

- Improvement of the environment, and

- Highly efficient processing of oil residues.

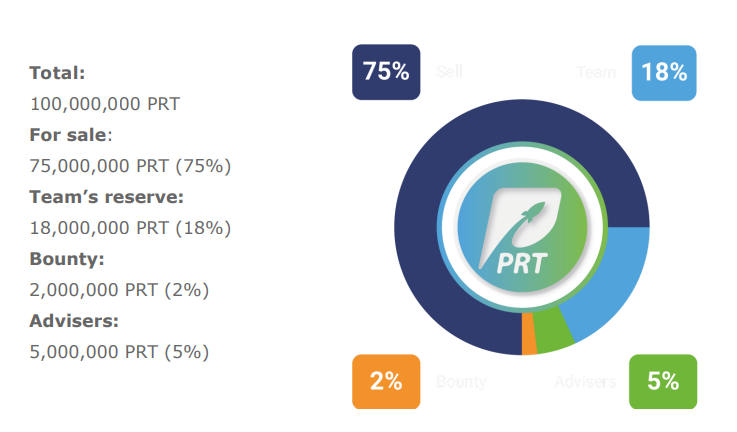

ICO DETAILS

Date: August 22 - October 22

Token name: PRT

Blockchain: Ethereum Standart: ERC20

Minimum amount: 100 PRT

Soft Cap: no

Hard Cap: 13,500 ETH

Accepted: ETH Total tokens: 100,000,000

Available for sale: 75%

Price of the token: 1 ETH= 3,500 PRT

DISTRIBUTION OF FUNDS

MEET THE TEAM

Thank you for reading.

To know more about this project, you can visit:

- Website: https://papusha.io/

- Whitepaper: https://papusha.io/files/Whitepaper_ENG.pdf

- Telegram: https://t.me/prt_chat

- Facebook: https://www.facebook.com/Papusha-Rocket-Technology-241396259943698

- Twitter: https://twitter.com/papushatech

Bitcointalk profile link: https://bitcointalk.org/index.php?action=profile;u=1956531

ETH Address: 0xAb5501225C2E6c0500d6bc5Aaf419a9D34b40EB0

Hi! I am a robot. I just upvoted you! I found similar content that readers might be interested in:

https://papusha.io/files/Whitepaper_ENG.pdf