You probably think this is the final part and I finished the blazer? Well, you are totally wrong :-D. I wish I was finished today! So many things still need to be done before I could start sewing. This is professional work, so no speeding and I can tell you that all fashion designers demand professional work.

The blazer need some fusible interfacing. That is a thin material with glue dots at the back that you iron on the wrong side of the fabric to give the fabric more stiffness. All fashion designers demand their blazers and coats to have fusible interfacings. It just looks so much nicer.

Here you see very clearly the glue dots on the back of the fusible interfacing. Fusible interfacings are in different types, heavy, thin, stiff and you have fusible interfacing special for seams.

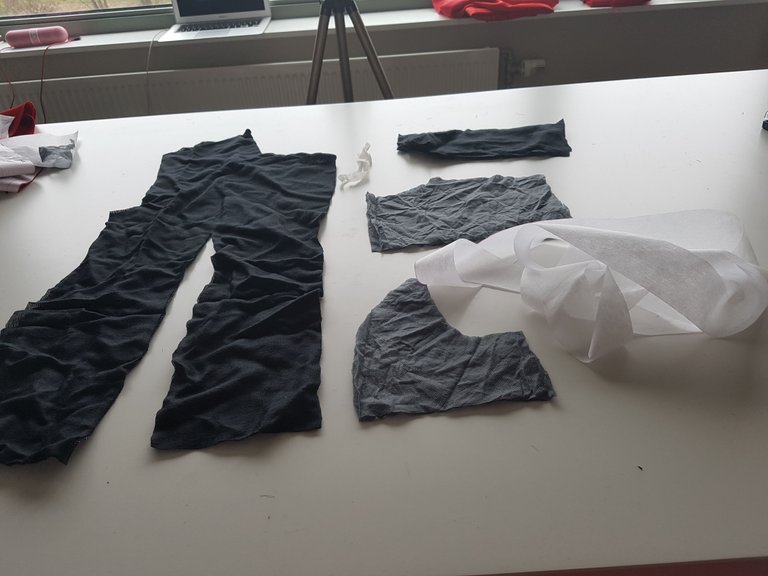

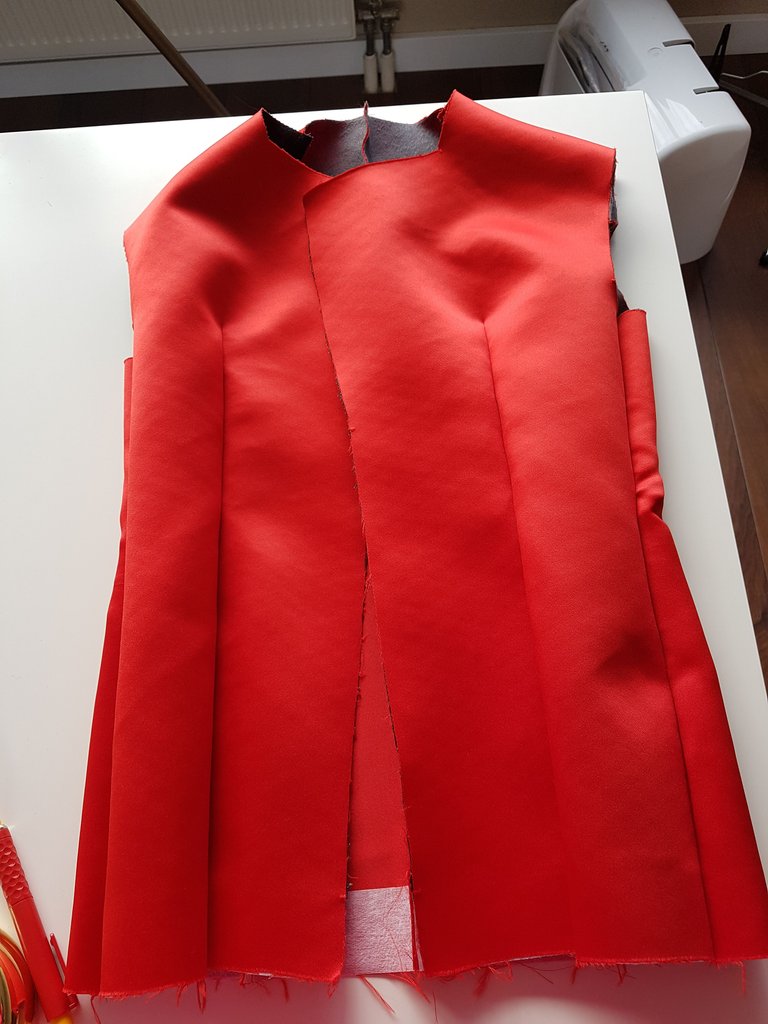

Unfortunately I couldn't iron the wrinkled fusible interfacing because it has glue dots at the back. So I had to iron with my hands. So these are the pieces I needed to use for the blazer. The front part of the blazer will be full of the fusible interfacing. Then the arm holes of the back and partly of the back. Then I need to use interfacing for the seams too.

I used a stiffer interfacing material for the front parts.

The back gets a much softer interfacing. Boy, that was a lot of work. It took me around 1,5 hour in total, cutting the interfacing and ironing them. The stiffer interfacing just didn't stick on the fabric as quick as I wanted, so I had to put the iron much longer on the fabric. Probably you think, why not just turn the iron hotter? Well, It would probably burn the fabric. In factories they have big machines, so everything would be done quicker. The machines have a heating bed on the upper and lower part and you just need to press it and it's done. SO doing it from home takes much longer.

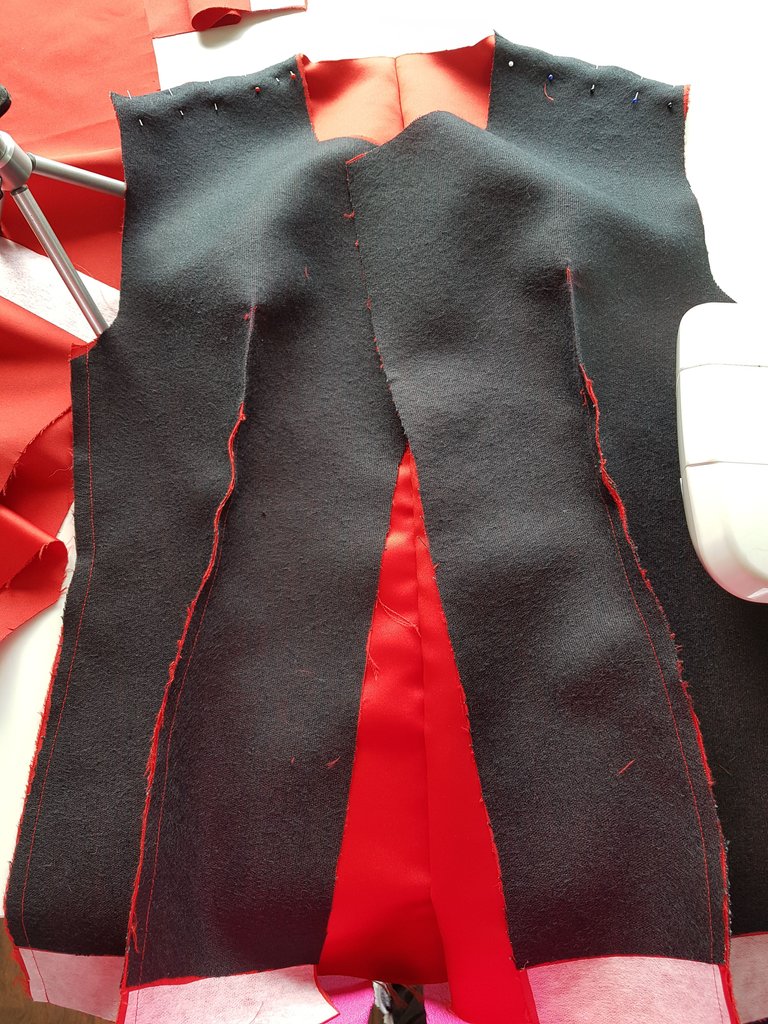

Sewing curves is a challenge. I had to use many pins.

Here you see the blazer from the inside. Your blazer looks like this too.

After I sewed the front with the back I had to open the seams by ironing them.

Meet Adjustable Diana, she has the same measurement like me. She is a Junior because my measurements matches a child's hahahhaha! As you can see Diana fits the blazer.

Here you see the back of the blazer. You see the curves I was mentioning. Sewing anything curvy is a real challenge.

Luckely I have a sleeve ironing board. So I sewed the sleeves that existed of an upper and lower sleeve.

Then I needed to open the seams of the sleeves. So that is why I needed the sleeve ironing board.

The sleeves are done.

I still need to do the upper and lower collar. Then I need to do the lining, connecting the sleeves which is a challenge because as I mentioned before, sewing anything curvy is a challenge and I need to stitch the blazer together. Oh, I also need to make a button hole and stitch the button on the blazer and as finishing touch ironing the entire blazer and hoping it will fit me good enough.

▶️ DTube

▶️ IPFS

wow thats quite good!!!

Thank you :-)

It was so creative friend @fathin-shihab.

You've never ceased to amaze me! Proses yang panjang banget ya untuk bikin sebuah blazer. Cuma professional sewist yang bisa. Btw, di Belanda ada ngga sih semacam tempat untuk menjahitkan baju? Kalo ada, ongkosnya mahal banget ya?

Terima kasih :-). Iya, prosesnya lama. Tapi kalau polanya sudah cocok, bisa di pakai lagi. Tempat jahit, maksudnya tukang jahit? Tukang jahit mahal! pendekkin celana aja antara 5- 10 euro! Kalau di Indonesia enak ya, apa saja ke tukang jahit. Saya juga suka itu.

Omg, mahal bangeet...! Mendekin celana aja segitu, apalagi kalo jahit baju kayak blazer gitu. Duh, duh, duh, berapa duit itu ....Berarti kalo punya skill sewing itu sangat berguna ya @fathin-shihab, membantu mengamankan dompet hahaha

iya, sangat berguna. apalagi kalau ukuran baju kita kecil. jadi bisa mendekin celana sendiri.

woa amazing talented :)following you

hope to have more post like this in future

Thank you @sarah.baloch. I will have more posts like this in the future :-)

Dayumnn girl!!! 👌 You have some serious skills and love for what you do. I don't even own an iron, and here you are with a sleeve iron (first I've ever heard of it!).

I'm late to the series so I'm gonna go catch myself up.

I love that red!

Thanks @bearone :-). You don't have an iron? I can not imagine that :-D.

Oh my, oh my, this is more work than I thought when I read part 1 @fathin-shihab. I have to say that the fabric looks very chic, the blazer is already looking very expensive, even though it is not finished yet. Good luck with the finishing phase @fathin-shihab.

hahahaha, yes, it's a lot of work. The blazer is getting its shape and looks indeed chic. Thank you @diamondinform.

wow it is coming along so nicely and perfect this is awesome :D

The blazer is really taking shape and coming together.

Do you also come up with the designs yourself or do you use a template of sorts?

I'm not really sure how that whole process works.

I'm also wondering how long that whole process takes you - it seems like a lot of work.

I replied your comment yesterday, but somehow its gone....

Yes , its taking shape now :-). There was an example design that I redesign it again. This one will take me around 17 -18 hours. Some are faster than others. If there are things that need to be changed, than i can add an extra hour or more on top. Thank you for watching and reading!

Wow. 18 hours. That sounds like a lot of work.

Very cool :)

:-)

nice video@fathin-shihab

thank you for sharing

You're welcome :-)

Hope for the best ,it sure will come out for the best !

I hope so too. Thank you :-)

Looks shitty.