I haven't done any board level work in five or so years. Everything I worked on then was old government spec stuff.

I haven't done serious board level work on new stuff in 20 years.

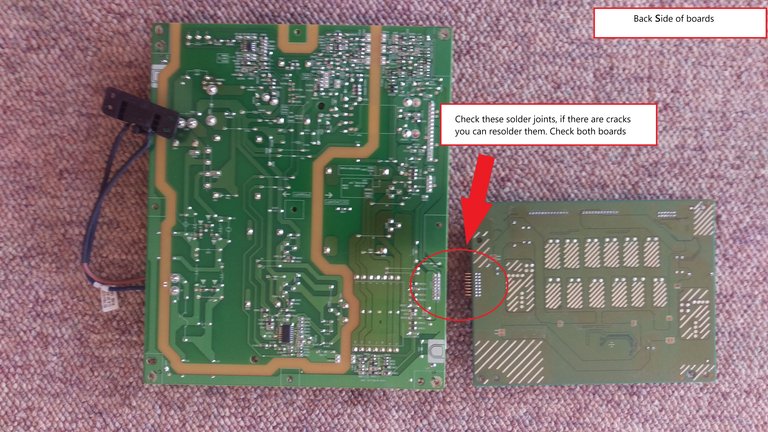

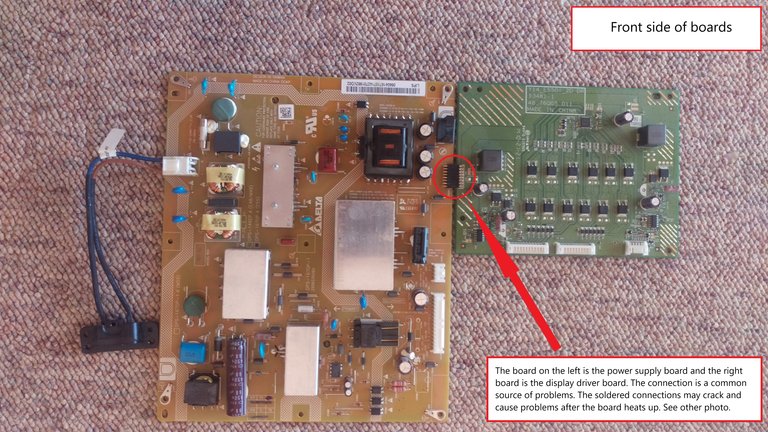

So, as soon as I get some time to take my TV apart I'm going to do some soldering. I've gotten pointers on the probable issue from someone in the know on my model of TV -and I'm sharing the advice I got below, not pictures of my actual boards but they should be the same- stupid ROHS. It's likely/probable there's going to be some bulged capacitors since I'm going to be dealing with a budget TV, even though I've been told it's most likely those solder joints.

Since my previous motherboard advertised "Solid Japanese Capacitors!" on it so big, I'm going to assume those are much better than the standard electrolytic capacitors that tend to bulge and dry out over time. Indeed that board did last quite a while.

SO:

Is there any reason I can't drop in solid capacitors like these instead of normal cylindrical electrolytics?

Is the voltage rating on those a maximum voltage rating? I'm assuming they should still function as their rated values even at lower voltages right? (I don't know what voltages the board runs at, considering what it does it could be stepped up or stepped down to just about anything - though I'm assuming modern LED light TV's don't need a massive step-up like cold-cathode screens did)

Are there brands/manufactures I should favor or avoid? I'm quite capable, it's not my first rodeo, but I've focused my attention in other parts of the electronics world in the past 20 years since I did manufacturing.

cool !!! electronics is a revolution