Hey everyone!

Another day, another blog regarding engineering as promised. It's been an awesome but quite busy day, hope your day has been great as well! I'm rather exhausted as I've been sleepless for days, however I felt like I would appreciate my bed even more by staying away from it for a couple more hours, so here I am! Enough whining.

This time I'm taking the chance to share some technical information regarding concrete, one of the most significant composite materials used in construction. We will discuss concrete composition and analyze the differences in binding materials, as well as the different attributes and behaviours between the different types of concrete manufactured and most frequently used in construction. I will also share technical information concerning each and everyone of the seven main categories of concrete specifically. I will try to make this a little less boring than it sounds, so stay with me!

Image Source: pixabay.com

CONCRETE COMPOSITION

Concrete is a composite made of construction aggregate that consists mainly of coarse and fine. The addition of a fluid cement paste that hardens is essential for the mixture's bonding. Most commonly used concretes are generally lime-based or even concretes manufactured using hydraulic substances that adhere to other materials, such as Portland cement. However there are categories of broadly used concretes that are not lime-based such as Asphalt concrete, which is often used in the construction of roads, and Polymer concrete, which is a type of concrete that utilizes polymer instead of lime-type cements to achieve bonding.

By mixing coarse aggregate with water and dry cement, engineers achieve to form a slurry paste that can be molded and placed precisely. Concrete is then born, as the product of successive chemical reactions between cement and water, and forms a tenacious technical material which has proven to be extremely versatile and therefore frequently used in construction. The physical properties of concrete can be controlled and manipulated in order to improve the final product's attributes, performance and behaviour with the addition of siliceous materials which in the presence of water can form cementitious compounds, such as pozzolans.

Regarding Structure Construction, the term concrete is frequently used to describe a wide range of technical materials which utilize binding agents in order to produce a solid formation from dormant aggregate. Ordinary concrete consists of water, a mixture of gravel and sand, and a binding agent which is regularly cement. A huge variety of different end products is feasible by using special chemical foaming agents in order to produce essential air voids. Moreover, accomplishing a wide range of end products is also possible by utilizing different sorts of binders, or by changing the volume or components and ratio of the aggregate.

One of concrete's huge disadvantages is its inability to resist against tensile forces. Therefore the use of prestressed reinforced concrete is essential for structures that demand strength against torsion. In most cases the product is poured with reinforcing steel, ingrained to administer tensile strength and resistance against mechanical distortion. Due to the material's fluid and formless nature, the process of placing it precisely is rather costly. Engineers managed to overcome this obstacle by utilizing factory precasting in permanent forms.

Concrete Production Unit by Badger Meter./ Source: badgermeter.com

CONSTRUCTION CONCRETE MAIN CATEGORIES

There are seven main categories of concretes that are broadly used in the construction of buildings and massive structures nowadays, each and everyone of those serving different technical purposes. Variations between those end products are achieved through the use of different binders and aggregate differentiation. The aim of this process is to create concretes with different attributes and bulk cost. The seven main categories are mentioned below:

Ordinary Stone Concrete

Structural Light-weight Concrete

Insulating Light-weight Concrete

Gypsum Concrete

High Early-strength Concrete

White Concrete

Expansive Concrete

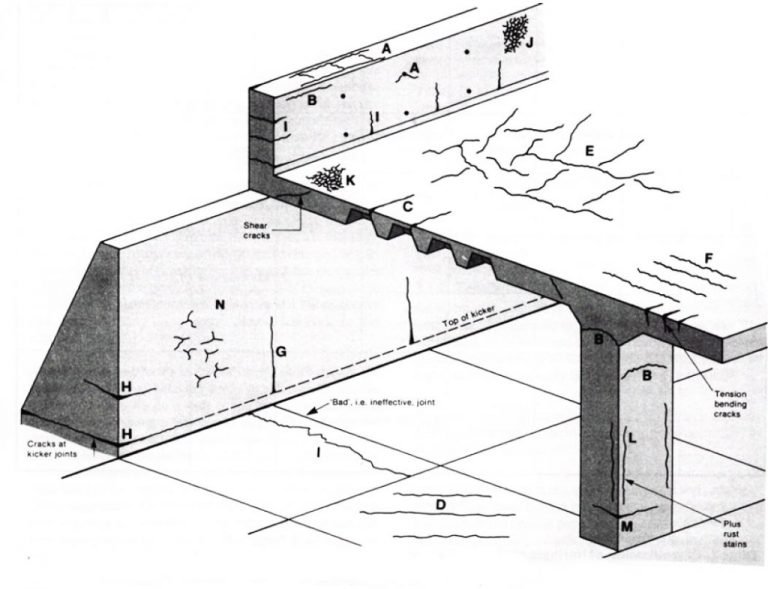

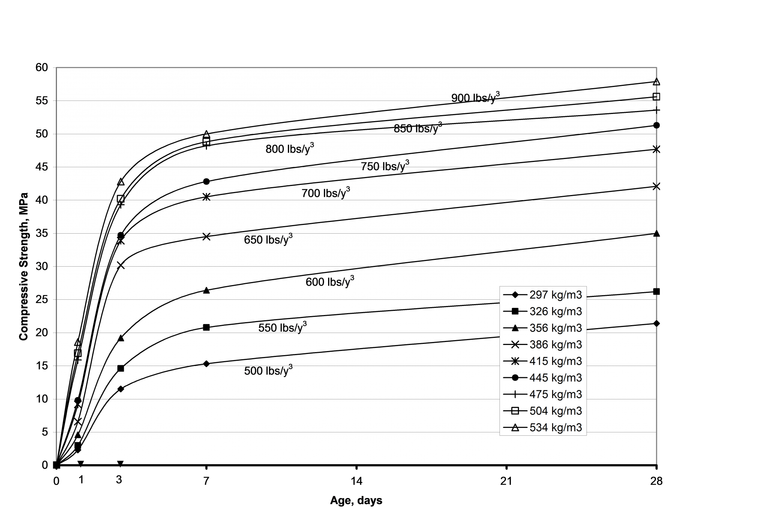

Types of Cracks in Concrete (A)./ Source: cemsolutions.org

Types of Cracks in Concrete (B)./ Source: cemsolutions.org

Now let's take a deeper look at each one of those seven main categories.

- Ordinary Stone Concrete

Ordinary stone concrete is also known as the material of sidewalks and pavements. It is also broadly used in the construction of foundations. Most frequently used binder when manufacturing ordinary concrete is Portland cement. Regarding the aggregate used in the mixture, it mainly consists of gravel and sand in a ratio that serves the purpose of creating a familiar rock like substance of considerable weight that is capable of withstanding extremely high compressive forces. While it's mostly preferred for its low cost, which is one of its several attributes along with its resistance to moisture and fire, it can also be manipulated to adjecture a wide range of forms.

Structural Light-weight Concrete

Structural light-weight concrete is pretty much the same as ordinary concrete, with the slight but important difference of some special sort of aggregate being used in order to substitute the gravel, with slag and expanded shale being included as alternative options. This different approach has the desired outcome of combining light weight and considerable strength, which is a win - win situation regarding engineering in any case! As a result, weight reduction of up to one-third of the initial values is accomplished with no loss of strength whatsoever. Needless to say this makes structures cost efficient. Inevitably there are trivial losses in stiffness, a fact that induces higher costs of the special aggregates utilized, however the expenses are compensated by the reduced overall weight of the structure.Insulating Light-weight Concrete

Insulating light-weight concrete is manufactured by utilizing a rather lighter aggregate with technical behaviours that resemble mineral substances in standard temperature and pressure conditions. The contribution of a foaming agent that provides the necessary air voids is essential. That way a material that is five times lighter than the equivalent of an ordinary stone gravel concrete is produced. However this advantage comes with an inevitable loss of strength which is frequently approximately proportional to the weight reduction. This specific concrete is broadly used as insulating fill, as well as fireproofing material.

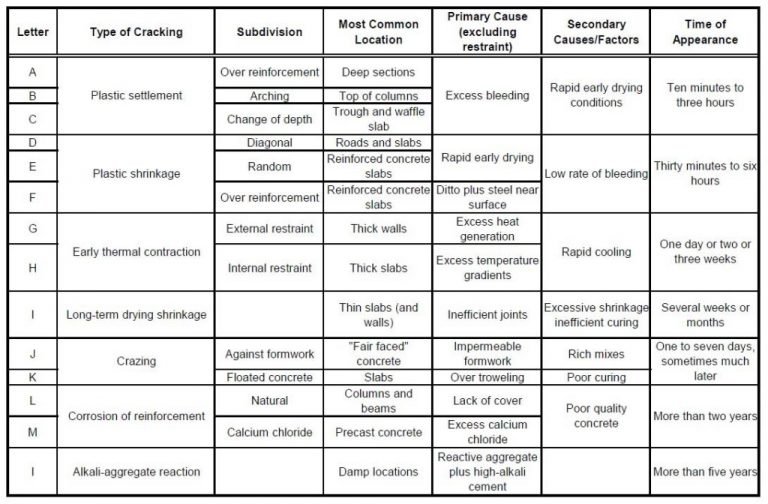

CSA Compressive Strength - Water to Cement Ratio./ Image Source: concretecountertopinstitute.com

Gypsum Concrete

Gypsum concrete is produced by mixing cement, sand and gypsum plaster. It is a concrete highly related to insulating light-weight concrete. The difference is the binder in this case consists basically of gypsum, however the aggregate used is common in the production of both concretes. This material is rather lighter than ordinary stone concrete. Just like insulating light-weight concrete, gypsum concrete is most commonly used as fireproofing material and insulating fill. It can be utilized for sound reduction and radiant heated purposes as well.High Early-strength Concrete

Highly early-strength concrete is a special type of concrete, produced with cement of accelerated strength gain. This is a special sort of cement used in various cases where rapid usability is demanded. This need is generally induced by multiple factors, depending on the weather, topography, pressure and humidity. Temperature is of vital significance as well. Accelerated strength gains provide engineers with the ability to use high early-strength concrete in one fourth of the usual time in such cases. This advantage comes with unavoidable loss of strength in extreme conditions.White Concrete

White concrete is manufactured using special technical materials. The utilization of special white cement along with white sand and coarse aggregate give birth to a precious concrete which comes with multiple construction and industrial applications. This concrete is lighter than stone concrete and more expensive due to a more sophisticated process of production and the utilization of rare raw materials. The virtually antiseptic mixing in combination with the factory's forming equipment give birth to a sparkling white product which is much more attractive than the normal grey-coloured concretes.Expansive Concrete

Expansive concrete is produced by chemically altering cement, thus causing it to yield slight expansions of its mass during the process of curing. This is frequently used to accomplish neutralization of the normal volume loss due to depreciation. One of the end product's most significant uses is the creation and preservation of the basis for self-prestressing concrete. This is a considerably heavy concrete due to the coarse and fine aggregate utilized in the binding process. However this comes with the principal advantage of the total elimination of potential cracking. This is a rather useful attribute as crackings are generally caused by normal shrinkage.

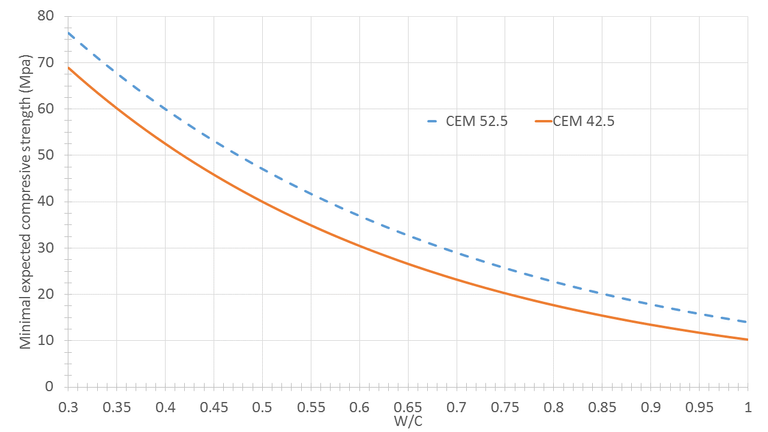

Compressive Strength Variation for Different Density Concretes. / Source: constructionspecifier.com

IMAGE SOURCES:

REFERENCES:

University Textbooks & Lecture Notes:

Σχεδιασμός Κατασκευών από Ωπλισμένο Σκυρόδεμα / Reinforced Concrete Construction Design - KATTIS MARINOS (National Technical University of Athens, School of Rural and Surveying Engineering course lectures)

Ωπλισμένο Σκυρόδεμα - Ελληνικός Κανονισμός 2000, Εκδόσεις Συμμετρία / Reinforced Concrete - Greek Regulation 2000, Symmetria publications. -GKROS R. GEORGIOS (National Technical University of Athens, School of Civil Engineering university textbook)

Τεχνική Μηχανική (Αντοχή των Υλικών), Εκδόσεις Συμμετρία / Technical Engineering (Strength of Materials), Symmetria Publications. - MARKETOS EVANGELOS (National Technical University of Athens, School of Rural and Surveying Engineering university textbook.)

Tεχνικά Υλικά / Technical Materials - MICHAEL SAKELLARIOU (National Technical University of Athens, School of Rural & Surveying Engineering course lectures)

Internet Links:

Thank you for your attention!

Hope you enjoyed this post and did learn a thing or two.

Follow me and stay tuned for more engineering blogs.

Highest Regards

@lordneroo

Being A SteemStem Member

Engineer Skills displayed beautifully 👍

Thanks!

Can a statue be precasted and made with concrete? If so what would it be like compared to the usual metals used in bad weather conditions? Thanks for sharing. I learned a lot :). Joy

@sweetjoy Hey Joy, that's an interesting question there!

I'd like to inform you that precasted statues made of concrete do exist! It's a technique that has been used for a while. As you can realize, the demand for strength and resistance against mechanical distortion is rather low when building a statue, as statues are very rarely designed to withstand forces. However concrete structures are more resistant to severe weather conditions due to the fact that concrete is an inert material and therefore the structure's strength isn't affected by the presence of molecules of water.

Concerning the cost, concrete is a composite material so the expense of gathering all materials needed is not fixed as it depends on geography and topography. In parts of southern Europe for instance it's much more cost efficient to use concrete, whereas in the US lumber is preferred. This is highly relevant to a country's economy and natural resources.

I assume that building concrete statues costs less than doing so using metals. Mining, processing, shaping, molding and carrying around metals comes with certainly bigger expenses.

Thanks for your comment!

Thank you for helping me in researching this. Joy

My pleasure :)

Civil Engineer AUTH here.

You reminded me days of old ... :)

Glad this brought back memories!

Thanks for dropping by! ;)@iliasdiamantis Good to know, Ilias!

I'll tell you what, the Universe provides!

I have been thinking about writing a short story, where I need some more information about concrete and building structures! Thank you so much for providing all this super interesting and easy to read through info.

What I am looking into, is making a Concrete composition with spores and mushroom mycelium/ground up mushrooms. That would work perfectly with the "Structural Light-weight Concrete" with the addition of gypsum, which some mushrooms love.

The idea is that there was an earthquake in some major city, where there was a lot of damage to buildings, sidewalks, and most minor structures. A company hijacks Cement trucks and local Concrete businesses to illegally introduce mushroom spores and mycelium into the concrete.

The people in charge are preparing for a major Thunderstorm/Rain event, which would soften the concrete and allow for the mushroom fibers to spread through the buildings and further break them, tearing them down, and reintroducing nature into the "Concrete Jungle" City.

Decomposition at its finest.

Is something like that technically feasible? What cement/mixture would you recommend to make my story seem factual/technical?

@skoolielove That's a freaking hilarious comment! Lmao!

I hate to disappoint you but concrete is an inert material. Therefore it won't chemically react with water which means that rainfall events do not affect a structure's strength.

Thanks for your epic comment which definitely deserves a lot more than I could reward it with!

Cheers! ;)

Thanks friend!

Concrete being the inert material, and mushrooms being the organic/active material, since its dark inside the concrete, and rain would make the spores/tissue come alive. It could even be the insulating concrete you wrote about, mixed in with dried yet live mushroom tissue. The mushrooms would grow/expand in whatever concrete mix, breaking it and collapsing it at a certain point. Mushrooms love eating through gypsum and using it for energy.

For fiction, anything is possible.

That could make a great fiction story. I mean you do have some valid points, however fiction should definitely be the primary tag of your post unless you find another way to decrease the concrete's strength. :p

introduction post

Check out the great posts I already resteemed.Resteemed by @resteembot! Good Luck! Curious? Read @resteembot's

ResteemBot's Maker is Looking for Work.

introduction post

Check out the great posts I already resteemed.Resteemed by @resteembot! Good Luck! Curious? Read @resteembot's

ResteemBot's Maker is Looking for Work.

Excelente publicación.

This post was upvoted and resteemed by @resteemr! Thank you for using @resteemr.

Introduction of resteemr.@resteemr is a low price resteem service. Check what @resteemr can do for you.

This post is Powered by @superbot all the way from Planet Super Earth.

Your post will Appear in the feed of 1100+ Followers :)

So don't waste any time ! Get More Followers and gain more Visibility With @superbot