What is cradle-to-cradle design?

A linear economy is arranged like this: Take. Make. Waste. After we take things from the earth (minerals, lumber, soil, etc.), we make things. Once the things we make have no further use, then we waste things. Take your refrigerator for example. An average refrigerator requires the minerals Hematite, Chromite (stainless steel), Galena, Copper, Cinnabar (thermometer), Pentlandite. That fridge required a huge amount of time and money to create! But when someone goes to the store to buy a fridge, they’re well aware that someday it will stop working. Companies also realize the fact that their products will eventually become waste and it budgeted into the balance sheet.

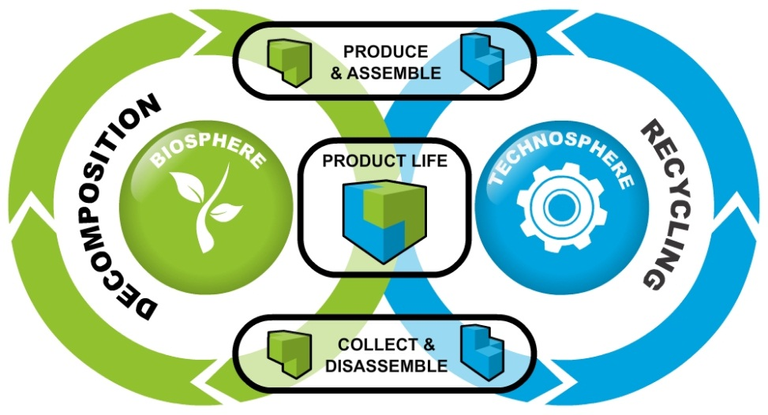

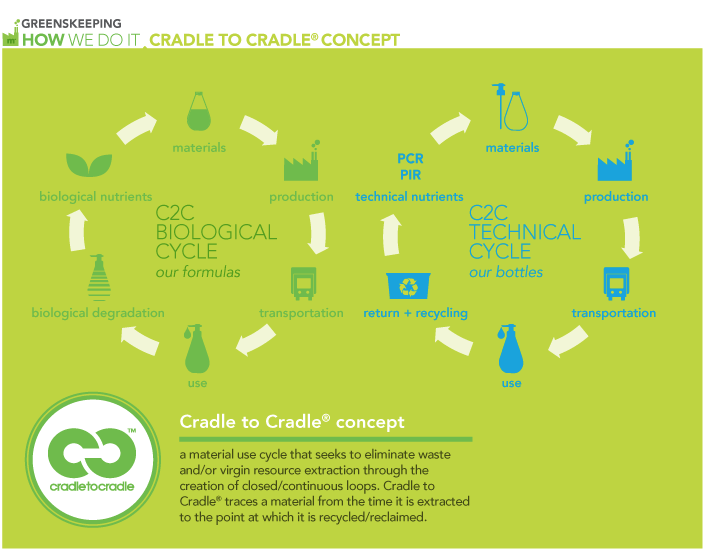

Cradle-to-cradle (C2C) is a regenerative design process. C2C is defined as, “a biomimetic approach to the design of products and systems that models human industry on nature’s processes viewing materials as nutrients circulating in healthy, safe metabolisms.”

What C2C design aims to do is create a circular economy. A circular economy is arranged like this: Retake. Remake. Restore. By creating products that are inherently regenerative from the start, not only will we improve the environment, but it also creates huge opportunities for financial gain.

A fascinating feature of this process is the potential for increased investment returns and reduced risk. For example, building structures. When a building is consciously put together in the beginning with the end in mind, then 15-20 years down the road, that building can have a set value attached to it. The materials can be removed and re-used. It stores a predetermined value. Therefore when assessing risk on a building of this sort, the buyer would be happy to know that they have reduced risk by locking in a commodity priced return on the building in the future.

Source: http://cmuscm.blogspot.com/2013/01/cradle-to-cradle-closing-loop.html

Here is a better explanation from the man behind C2C, William McDonough…

The other nice things for the banks is that we’ve been designing these buildings for what we call end-of-use, where we design for next use, intentionally. So, we’ll say, if the financing’s 15 years, and the leasing is 15 years, even on our office buildings, we’ll realize that we can design the building as commodities of the future. So, we can design them for disassembly and re-sale. So, if the bank, say, got stuck with the building, and had to take it down, under conventional construction they would have to pay to have it removed. In Europe, the office buildings are around 80-Euros a square meter for demolition and removal.

We’ve seen pre-pricing on some of our projects at 120 euros as an asset, because we’ve pre-priced the steel, following commodity trends, so that at the next use, if the bank wants to take the building down or sell it, then the first choice they have is to release it as an office building, which, of course is very practical. The next option is to convert it to housing, immediately, because it’s totally ready. So, that’s very cost-effective because there’s always a market for housing. The 3rd option is to have someone tear it down for a skyscraper or a park or something. They can get paid for it, instead of having it as a cost. Turn liabilities into assets.

The quote above is taken from an interview with William McDonough in Builder Magazine (http://www.builderonline.com/builder-100/strategy/circular-reasoning_o).

Incentive. This is the key feature of this design process in my mind. When something makes financial sense, the adoption rate can be staggering (think certain crypto currencies!). Once this becomes economically viable, the floodgates will open because it will separate environmentalism from the picture. The vast environmental benefits are already designed into the product, they are inherit, so an argument about the environmental and social impact is not needed. While it may seem counterintuitive to ignore these impacts, it is in fact the clearest path to wide spread adoption of these approaches. Cradle to Cradle design can have have a far-reaching impact on the health of our natural world and the prosperity of our social world. Why wouldn't we as a society push for the best possible products that are best for the planet?

What do you think? Are any of you involved in current projects related to Cradle-to-Cradle design? Have any ideas for product designs?

Thanks for reading - I find this subject fascinating and I hope you find it interesting too!

Source: http://methodhome.com/blog/greenskeeping/c2c-process/

I would question the time frame you are placing on buildings? 15 to 20 years seems shortsighted for the construction of a new building. A new structure should have aspirations of 50, 75+ years. Building systems can be updated, removed, recycled over that life, but to assume that a building payback and is disposable at 15 to 20 years seems ridiculous. Designing a "shell" to withstand time and can be easily upgraded for changes in use or upgrading for energy efficiency seems more reasonable and better for the environment.

Good point @simpleengineer... perhaps the 15-20 year range is not necessarily when the building is deconstructed. Rather, it's likely that ownership will change at some point around then and the new buyer will benefit from this reduction of risk? Thanks for your thoughts - best way for me to learn.