WARNING! This story is long, dumb and funny at the same time!

Oh crap... 3d printer, every person who has a 3d printer will unstand my feelings. I don't mean a giant 3d printer for thousands Euros, I mean the "cheap" printer. There are so many little things what you need to know about 3d printing, how the printer works, what parameter has which impact? Or if the printer runs really well, the filament is empty and the new filament is completely different then the other one. As I bought my 3D printer, I didn't know that it would be easier to build a new one, instead of optimizing it.

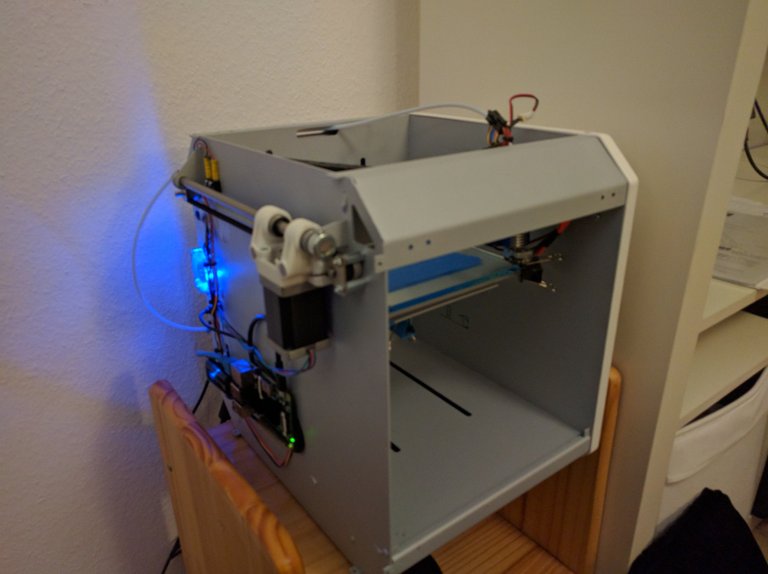

The printer I bought was a German RepRap NEO and it was good, totally worth it. A small printer, only one hotend and no heated bed, no fan or anything else. The printer does its job a few weeks, maybe a month, but not more. Then things started to happen…

The first thing that happened was a clogging extruder. The filament has the good property to absorb the complete dust in the room. I mean, who needs a vacuum cleaner when you have a Filament Roll.

The dust completely clogged the extruder and when I say completely, I mean definitely COMPLETELY! The extruder was done, nothing happened, I tried everything, heat a little bit and stick new filament on that to suck that clogged part out, nothing. I tried to clean it with boiling water and needles which was the “best” idea I’ve ever had….Nope, wont do it/the job. XD

So I decided to buy a new one, a better one which cannot be clogged, but when they clog they could be cleaned easily. So I bought the e3d v3 Hotend and it was awesome, really awesome.

So another week went over, and more things happened. The filament won't stick on the build plate. I tried so many things, hairspray, glue, tape, hairspray and glue, hairspray and glue and tape, sometimes it worked, but not always and that sucked. So I read tons of posts about that problem and found an interesting article about the phenomenon why hairspray and glue is sometimes working. There is a component called PVA. The PVA sticks the filament that comes from the nozzle directly on the plate.

I read that that temperature differences between the plate and the filament is very important, if the difference between filament and plate is too big, there is a surface tension that creates that effect.

I decided to do the “best way” and bought a heated plate and for the heated plate I also need a new power supply. The printer worked and a couple hours after printing a microchip on the circuit board of the printer fused. And the original circuit board was so cheesy that the microchip couldn't be replaced easily. So I bought a new one, a better one with parts that I can easily replace. (Sometimes the chips fuse [s.above] because the stepper motor creates very high temperature)

Another few weeks later I tried to print with the new circuit board and the new heated bed, but nothing… It didn't work, the filament wouldn't stick on that plate.

A few moments later I read that many person use wood lime with water. The lime creates a small film on that plate with high concentrated PVA, a few hours later the water will be evaporated. I was happy and bought a very thick glass plate, because the glass plate can be easily cleaned if the try with the glue will now work. I went to an DIY market and bought a huge amount of wood lime, the DiY market only sell huge and expensive bottle of that shit. dot, dot, dot

A few moments, a couple of brushes and the glass plate was done. A thin layer of wood lime was on it. I started the heating plate and waited for the right temperature: 80 degrees Celcius - not more, not less. After 60 degrees Celcius I notice that the glass plate is getting brown and a few moments later, the lime was black. My first thought was … what the fuck …, after a few seconds my seconds thought was … what the fuck …, I waited for the heated bed to cold down. At the same time I looked on the package of the wood lime and after that a few seconds of reading I realized that the wood lime is water resistent……

Fucking water resistent… There is no PVA and that shit burns at about 60 degrees Celcius. I tried to clean the plate, totally needless, it’s done, that plate will never work as a printing plate [again?], so I bought a new one, well….

With the new plate and a new wood lime it worked.... It worked good, but for me it worked too good, from the temperature increasment and cool down process the plate broke in the middle. A complete 6 mm plate broke completely. O.o

I mean ... what the fuck ... either I'm really dumb or my printer hates me. XD

I bought a printer for fucking 500,00 Euros and invest more into repairs than that thing has costed [been costing wäre progressive, also verlaufsform]. XD

That’s a short story of my 3d printer and why I said that would be easiest to build one from scratch. I hope you enjoyed it. If you want I can write good sides of that printer and give you some tips for 3d printing. (:

I mean I have made everything wrong what a person can do wrong. XD