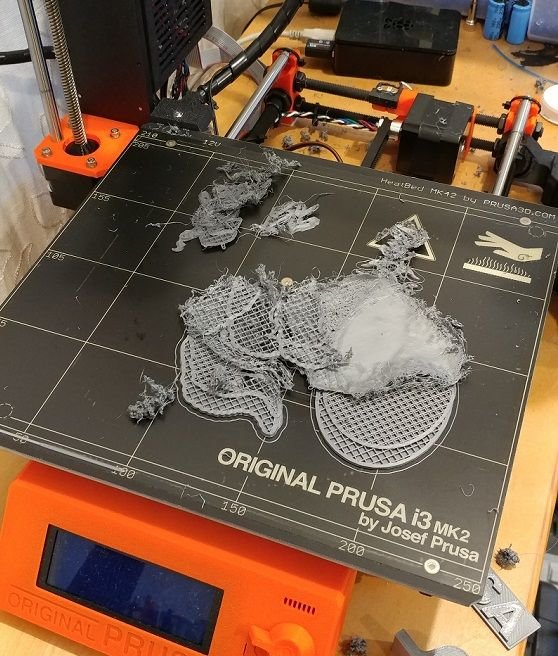

So I ran a 3d print last night, and in the morning I woke up to this beautiful bit of plastic carnage:

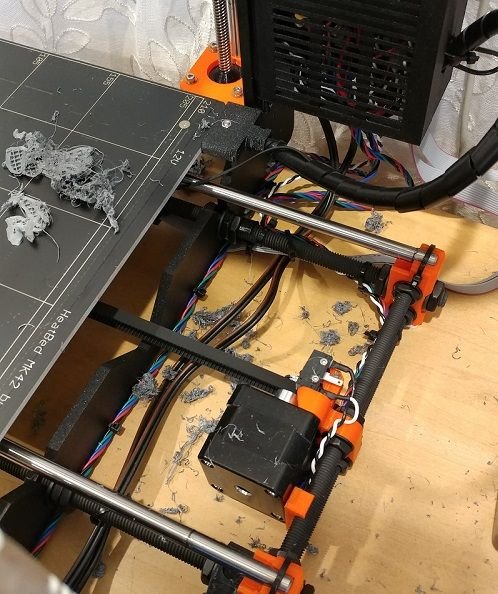

There was some debris in the back:

And don't forget the nozzle:

I'll be honest, when I started the print I hadn't really expected my printer to attempt it's own version of Laburnum. To put is succinctly, this was a catastrophic failure. Though as much as I was annoyed at having to clean it, I also found it kind of funny since it was completely unexpected.

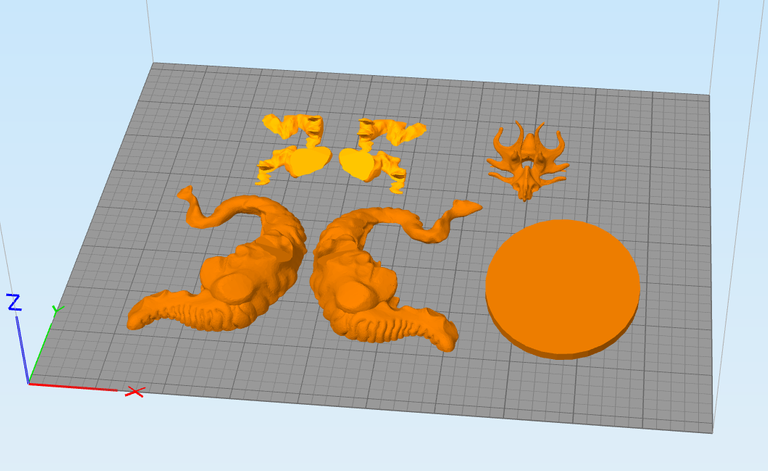

For reference, here's what I model(s) I was printing was supposed to look like:

It's the first few parts for the forest dragon model on thingiverse.

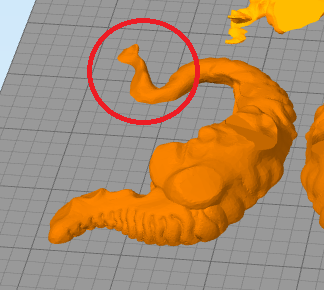

So why did this happen? Well, it's because of this little part right here:

Specifically, what happened was that part of the tail in the red circle didn't correctly adhere to the bed for some reason and curled up during the print. I actually noticed this during the early part of the print, but thought at worst it would just result in a shifted print. And at first it wasn't too bad - warping sometimes happens during prints like this but it's not usually a problem. Not so in this case. The problem was that as the printer kept running the head over that area and added plastic to it, the curled part became stronger and stronger with the additional plastic only adding to that curling effect until eventually the head got caught on it and it reached a breaking point. Once that happened, it was over. The part explodes off the board because of the pressure from the print head, debris flies everywhere, sad looking print.

I have seen failed prints before, but nothing quite like this. The printer still works though so I guess it's a relatively inexpensive lesson in knowing when to pay attention to early warning signs in a print. But hey, at least now I get to say that my printer made a dragon explode :)