Before entering fully explain the different constituents of a refinery I think it is important to understand how oil is constituted and what the refinery's objectives will be when working with it. All this is included in this article, while in the following writings I will focus on the different processes that are carried out within a refinery.

ORIGIN AND FORMATION OF PETROLEUM

Petroleum is organic matter formed mainly by hydrocarbons and of fossil nature, result of the transformation of the matter of vegetal origin during long periods of time. It is also known as "crude", indicating that it is not a product for immediate use but that it must be transformed.

The fluid state of the oil has given ease of movement to the site, being in places other than its formation. The hydrocarbons formed are driven by high pressures and migrate through the porous layers of the crust to find biological formations where they are retained, usually a fault or an anticline. The liquid hydrocarbons formed are accompanied by gas and salt water (distributed by density). Salt water justifies its marine origin.

Oil extraction is produced by drilling the layers above the reservoir. If the deposit has enough pressure the oil will rise and if it does not have it, it will be pressurized (with gas or water).

Oil refining

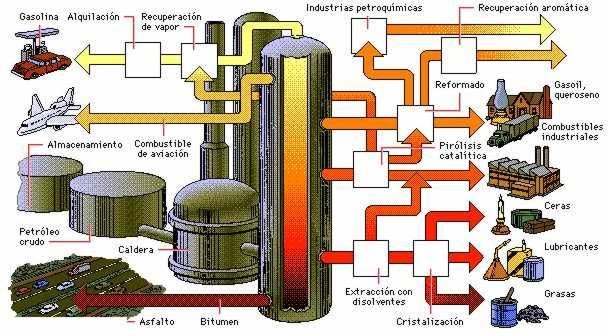

Oil refining is a process that includes the fractionation and chemical transformation of oil to produce commercial derivatives.

According to this objective, in general, these processes are carried out together in a refinery. The refinery is where the oil is treated to extract commercial fractions.

Oil is a mixture of different hydrocarbons, which must undergo a series of different treatments to be used in combustion engines and in the various branches of industry. Very often, the quality of the oil is highly dependent on its origin. According to its origin, color, viscosity, its sulfur content, the pour point or its mineral content vary. Therefore, refineries take these factors into account.

A refinery must be designed to handle a wide range of crude oils. Of course, there are refineries designed to process only a single crude, but these are special cases where the estimated gross resource is very important.

There are simple and complex refineries. Simple refineries consist of only a few processing units, while complex refineries have many more.

In the countries that have them, the refineries are installed preferably on the coasts, to save transport costs and construction of oil pipelines.

The crude, once arrived at the refinery, is stored in large deposits. In general, the crude oil is stored according to its sulfur content, the low content (BTS) is stored separately from the high sulfur content (HTS). The same happens in the treatment. According to market demand, the BTS is first treated in a cycle before treating an HTS cycle to avoid contamination of BTS products by HTS products. If the opposite is the case, the products passed a few hours after they are processed, where appropriate, are directed to the containers of HTS products for reprocessing.

Structure of a refinery

In the refineries it is transformed to oil that is composed of thousands of hydrocarbons in fractions, of composition and approximately constant properties, which distill between two preset temperatures. The refineries have different complexity according to the different installed plants. Its main products are naphthas, kerosene, gas oils, diesel and fuel oil.

GENERAL SCHEME OF THE REFINERY

The refinery must meet 4 objectives:

An adjustment of the volatility of the fractions.

Oil is a mixture of many hydrocarbons that has very different boiling points (which is not suitable for fuel applications). It is necessary to make intervals with the boiling points, that is, a fractionation. To divide the crude, several units are differentiated:

- Atmospheric distillation unit

- Light unit

- Vacuum distillation unit.

Qualitatively adjust the fractions.

Some of the fractions do not have the appropriate hydrocarbon structure and must be transformed to obtain a suitable quality fraction. The following processes are distinguished to carry it out:

- Catalytic reforming

- Isomerization

- Alkylation

- Obtaining ethers.

Quantitative adjustment of fractions

It is usual for the market to demand a greater proportion of light fractions than those obtained in distillation. The next objective is to transform the heavier fractions into light ones to adjust to the demand. This is achieved through the conversion processes, which are of two types:

Thermal processes:

Units: - Visbreaking - CokingCatalytic process:

Units: - Catalytic cracking

- Hydrocracking

Stages of oil refining

Hello,

We have found similar content: http://www.ingenieriaquimica.net/articulos/311-refino-del-petroleo-introduccion-i

Not indicating that the content you post including translations, spun, or re-written articles are not your original work could be seen as plagiarism.

These are some tips on how to share content and add value:

Repeated plagiarized posts are considered spam. Spam is discouraged by the community, and may result in action from the cheetah bot.

If you are actually the original author, please do reply to let us know!

Thank You.

More Info: Abuse Guide - 2017.

You received a 10.0% upvote since you are not yet a member of geopolis.

To read more about us and what we do, click here.

https://steemit.com/geopolis/@geopolis/geopolis-the-community-for-global-sciences-update-3

If you do not want us to upvote and comment on your posts concerning earth and earth sciences, please reply stop to this comment and we will no longer bother you with our love ❤️

!cheetah ban

Plagiarism - Soft

Okay, I have banned @joseferrer.