Well Hello There Horsepower Lovers!!

All For Nothing!

Well this really was a useless exercise! Okay not totally useless since I got the opportunity to practice a little! If we can call this practicing! But I have to say just because something is less significant it doesn't mean you should throw it away!

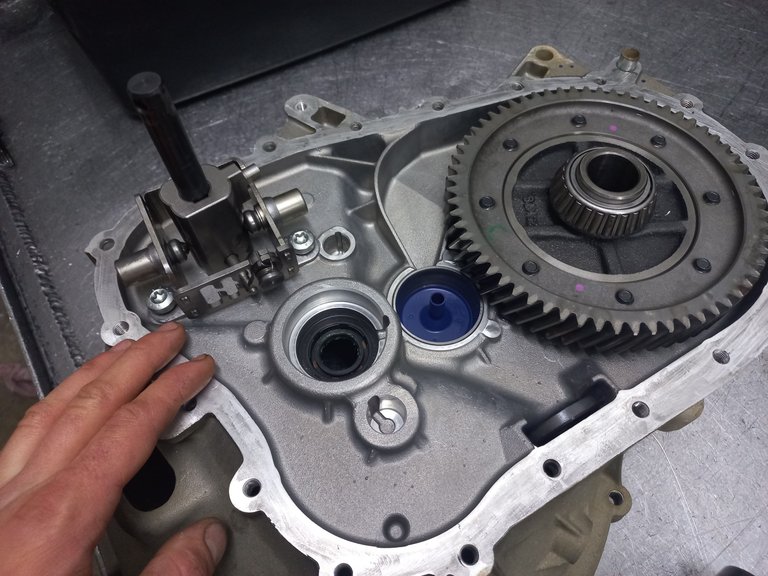

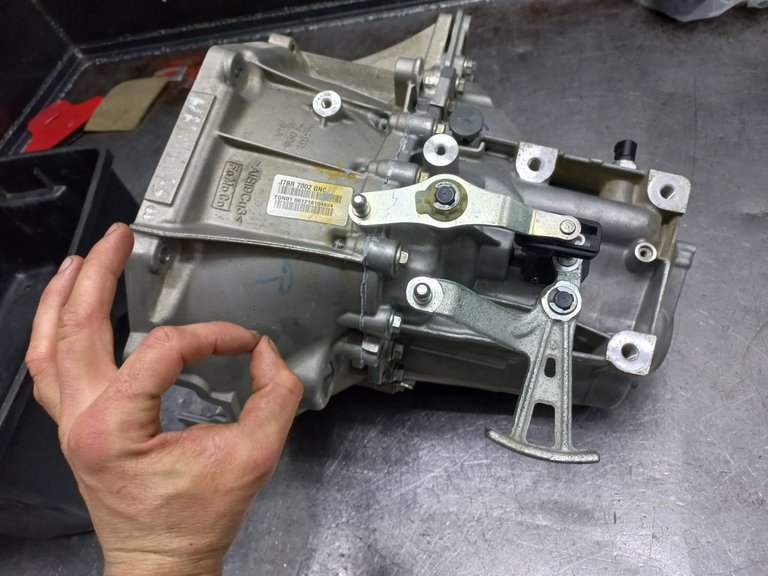

I got myself this nice Ford Figo transmission to close up! Let's run through it! Although there really isn't anything complex behind this! We also didn't tear it down to just parts, it was only a bearing failure on this one and we wont even be replacing that!

Almost Halfway!

Okay I might be exaggerating a little here but you can almost say so! Once the diff is in place it's all smooth sailing from here onwards! Lovely right?

Loving how clean this casing came out though. so I am going to put in a little bit of effort on this one even though they are going to scrap the vehicle, I don't want anyone pointing fingers at us for this or that!

As perfect as we could get it!

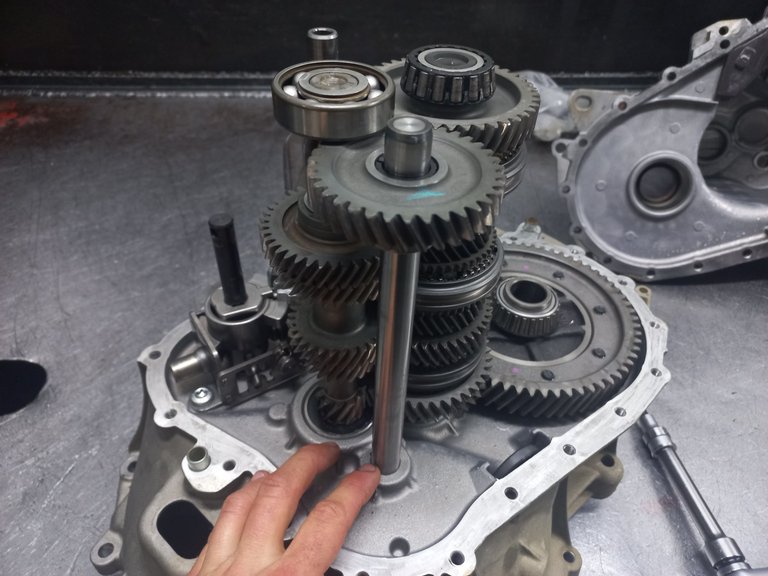

If I had a say I'd say that most of the work was in that selector over there! Heck getting everything lined up and then having to bolt the entire thing to the casing is quite the mission for a one man!

Sank Right In!

The real trick is getting those two shafts (Cluster shaft to the left and counter shaft to the right) in together and through the differential gears! Without breaking a bearing cage or the oil feeder as seen in the previous phote, that little blue thing!

The Tricky Part!

This can sometimes be the most tricky! Puzzling out the selector shafts! Now it's not something that I particularly struggle with but it's something to figure when you didn't do the teardown on the transmission!

I managed to get through it quite easily, this time though!

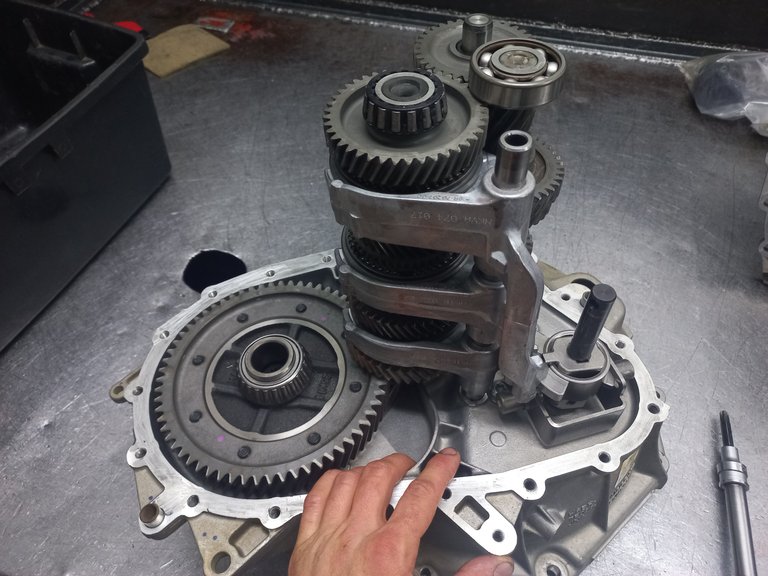

But coming this far I realized I made two major mistakes!

The first mistake I noticed was that I never inserted the idler (Reverse gear) I then had to remove everything to get it in place! So you've got an extra shaft so fit in with the rest! It had to be done because the gear runs underneath the bearing on this one! So there was no other way!

I also forgot to add the guide for the selector shaft! Heck! At-least this is like a few minutes of work so nothing major turned on its head though! Just had to puzzle it out!

Now we're getting there! Always make sure to double check! It's not nice sealing up a casing and then you have to remove it again! Oh that silicone turns into a mess real quick!

She's perfect and ready!

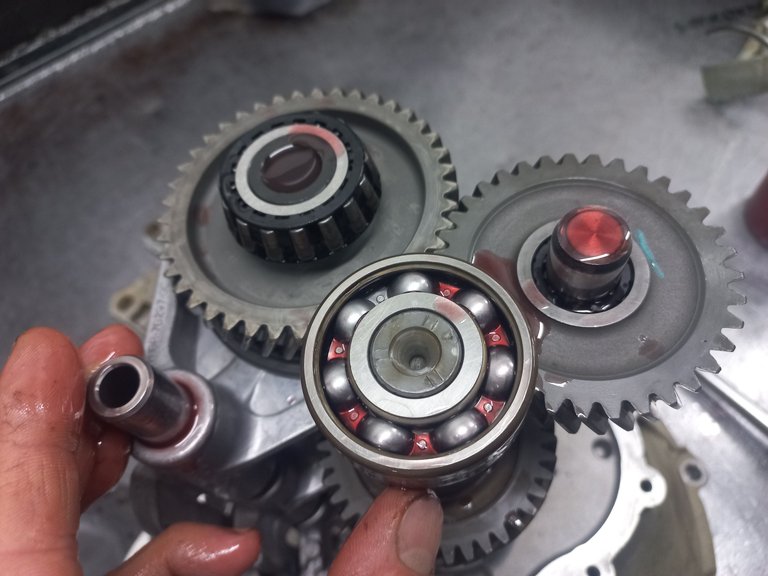

Oiled Up!

This is something that most people overlook!

Now for me personally I like having a casing just slide over everything! Why have the hassle to waste time with a hammer and all that? If you put oil on everything that needs to slide in the casing you can just hit it with your palm and have it done with!

Onto the next one!

Connecting the people of #HIVE across South Africa. #hive