As you know, I have a friend who's into tuning cars, and he's pretty knowledgeable about the modifications that can be done, partly because he knows the Highway Code very well.

His motto is:

Don't make the car go fast if you can't stop it

I think that's more than fair and reasonable.

Before we get into that, though, the usual disclaimer.

Everything I write is not an incitement to modify one's vehicle, but an "educational" treatise to better understand some mechanical aspects

As you may have guessed, we are talking about the braking system.

The brake system is made up of the brake calipers with their wear pads called pads, the discs on which the calipers act, the hydraulic pump for operating the calipers, and the brake fluid that is used as a means of operating the brakes.

The pump

I'd say it's pretty simple it's nothing more than a piston with a well-defined diameter that pushes oil into the calipers and causes the calipers to close on the disc.Between the calipers and the disc are the friction elements, but we'll talk about those later.

To make the strain on the brake pedal, less, we use a tool called the brake booster: you will all have noticed that if the car is off, the brake pedal feels very hard, while if the car is running, the pedal is soft.

This is due to the brake booster, which in this case is called a vacuum brake, that is, it uses the vacuum created by the engine intake to help push the pump piston.

The pump, as I mentioned just above has a well-defined diameter because the fluid thrust to close the calipers is calculated based on that; a change to the pump would mean a profound modification to the system with results that are not always the most efficient.

The liquid

The liquid that is used to push the pistons of the calipers is a special oil resistant to high temperatures: think that in a stretch of road a little twisty and with a drive with a rather sporty setting can reach 250 degrees C.

For this reason the oil is very important and must be replaced every 2 years, because being hygroscopic it absorbs moisture and in the moment when we need emergency braking when the oil reaches 100 degrees water evaporates and the compression force is relegated to a gas, which as everyone knows can be compressed.

In this situation the effect is transmitted to the pedal and it becomes "spongy"-it's basically like stepping on a tire, we feel some resistance but it's not the same as when the oil is at full efficiency.

A very important feature is that this oil is extremely corrosive to the car's paint so you need to handle it with care.

The oil has various gradations from DOT 3 to DOT 5.1; DOT 3 is no longer used, starting with 4 and up for cars with increasingly racing characteristics.

This means that if a car is born with a DOT 4 it CANNOT use a DOT 5, this is because the system is different and especially the replacement deadlines are different.

Although DOT 5.1 withstands very high temperatures, it is also extremely sensitive to moisture, so to maintain its efficiency it needs to be replaced more frequently.

The Calipers

We come towards the end of the system where we find the "three musketeers": the calipers, pads and discs.

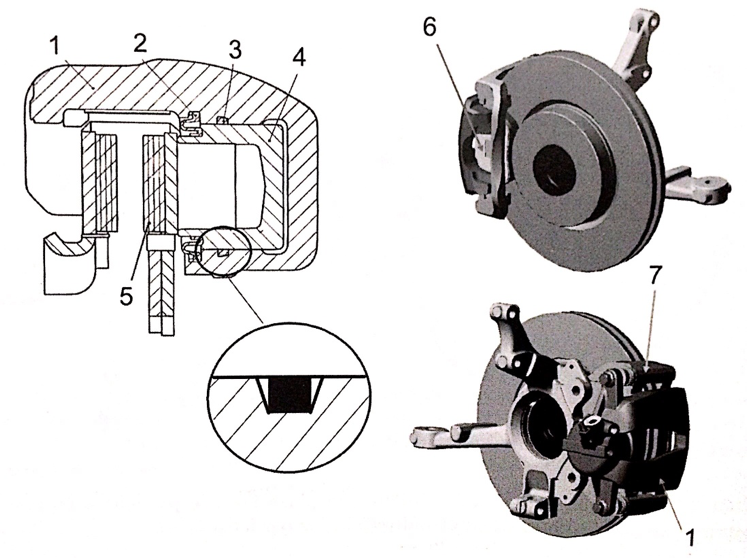

There are two types of calipers: floating and fixed.

Floating ones consist of a single piston that exerts pressure on a pad and by means of mechanical deflections the other part of the caliper, precisely floating, moves and allows the pad to press on the disc.

Fixed calipers, on the other hand, are divided into two mirrored parts and each has 1 or more pistons that press the pad onto the disc.

For reasons of braking modulability and balance, fixed ones are preferred.

Nowadays in the tuning environment, it is very fashionable to modify the braking system, and there are companies that provide special kits that are street-legal. Of course, the costs are prohibitive: they start at a minimum of 2,000 euros.

It's necessary to say, though, that these systems are designed by engineers and therefore have the same reliability as the stock system, only it's oversized.

So, once again, do not venture into experiments that are

dangerous to your and others' lives!

The Disks.

Well we have come to who really stops us: the disk.

Discs fall into two broad categories: the monolithic and the self-ventilating.

In turn, you can have various types of discs: smooth, drilled, whiskered, drilled and whiskered or Gr.N smooth.

Monolithic ones differ from self-ventilating ones because they are nothing more than a 1 cm thick cast iron rim, while self-ventilating ones are a sandwich with fins inside that dissipate the heat generated by friction.

The perforated discs serve to better cool the whole system and also dissipate the fading gases developed during braking.

It should be noted that it is necessary to choose discs of a certain quality otherwise, in the vicinity of the holes, cracks (cracks) can originate that undermine the stability of the disc.

The whiskers serve to keep the braking surface of the pad "alive," it follows, clearly, that consumption is greater; on the other hand, braking is safer!

The whiskers have a direction of rotation, depending on which has different results: with the whiskers rotating in the direction of travel, or against the direction of travel.

Racing direction whiskers are used for street use; in fact, they are less noisy despite keeping the pads performing.

Opposite direction whiskers are used for track use, where comfort is not important; in fact, they are noisy and vibrate excessively.

Speaking of which, this friend of mine, since his 75 has onboard rear discs, to keep them in full performance has fitted drilled and whiskered discs, and the fitment is racing.

FOTO DISCHI 75

When braking on the highway at high speeds, yes, I must say the comfort is just like a race car!

The concurrence of the whiskers and holes is for maximum performance of the system that cools well and the pads are always ready.

The Gr.N smooth disc, nothing but a disc very similar to the road disc, but with a higher coefficient of friction and material stability at high temperatures, really enviable. It must be said, though, that such discs are born mainly for track use, so for street use they are inadvisable because they cannot reach the right operating temperature.

The pads

Well we have come to the final part of the system, the component that performs the most important task.

The pads are nothing more than steel plates with friction material glued on them that presses on the braking track of the disc.

Also for pads there are of different compounds, from soft street to medium to hard or very hard that are purely racing.

For street use it's best not to go beyond medium, otherwise the stock disc after a few miles would have to be changed.

For excellent value for money-performance, with an original disc we can mount Ferodo DS2500s, your car will

totally change braking, try it to believe!

For today the "lesson" is over, see you next time!

La persona que realiza la reparación y cambio del sistema de frenos debe de ser una persona confiable o que lleve mucho tiempo realizando el trabajo ya que de eso depende nuestra vida es algo que hay que tomar en cuenta

The person who repairs and changes the brake system must be a reliable person or who has been doing the job for a long time because our life depends on it, something to take into account.

Translated and formatted with Hive Translator by @noakmilo.

Now this is the truth dude! Laughs and there's people that'll never change up those brakes!

!PIZZA

$PIZZA slices delivered:

(5/5) @technicalside tipped @mikezillo

Quite an interesting lesson you have given us in this post, covering the functional or operating parts of the brake system. One would have expected more details about the meaning of DOT, for example, but for sure that is something that can be googled, anyway.

Honestly, I have enjoyed a lot reading itHello @mikezillo

Thanks a lot