I take everything back that I wrote about using catapults for civilian planes. There is a much better solution waiting out there, to which someone pointed me after mentioning the catapult idea.

The Electric Ground Vehicle

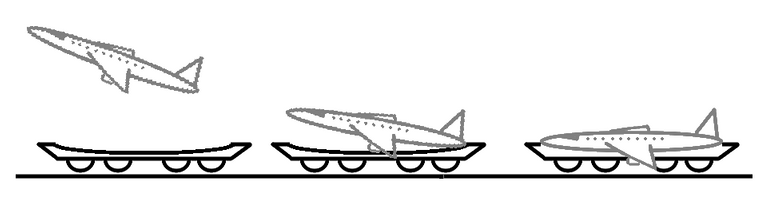

Instead of a catapult, which needs plenty of infrastructure, you could also use a big battery electric vehicle, on which the plane rests until it is fast enough to take off. The vehicle does not need a particularly big battery as it only has to carry the plane for the two kilometers on the runway.

All it needs is a very strong engine and a battery capable of delivering the power to the engines during the one minute acceleration phase on the runway. I‘m not an expert in the field, but I believe all of that is state of the art.

If you think of 50 Tesla Model S as a comparison, the electric ground vehicle would need a battery size of roughly 5 MWh. This value is based on the necessary top speed for the carrier that is twice as high as for a Tesla (plus the increased drag), but also considers that a Tesla has a range of more than 200 kilometers at top speed, while the carrier has only 2 kilometers to go on the runway. Therefore, a 5 MWh battery size should be sufficient to get the plane off the ground and have the ground vehicle drive back to the charging station.

What Does That Cost?

The electric ground vehicle would cost pretty much the same as 50 Teslas, which would be some 4 million USD. Since they need to be fully recharged after every take-off, while there is one take-off every two minutes, it would be logical to use removable batteries.

Assuming that fast charging is possible an takes 60 minutes, you need around 40 batteries and six vehicles to cover one runway (each one at the battery station, at the plane preparation, for take-off, the drive back, the battery replacement and one replacement vehicle).

As with electric cars, it is likely to have a cost ratio of 90:10 between the batteries and the ground vehicles. This would result in an investment of roughly 160 million USD for the entire system on one runway.

If you can use the batteries for 4 years until they need a replacement, you have around 40 million USD in total annual costs plus another 10 million USD for the personnel and the business part of the project. Divided through 100,000 take-offs per year, the system would cost around 400 USD for every plane that it is used for.

I would argue this to be very feasible. What do you think?