The homeowner tells us the house was built back in the 50’s and the shop was put in some 40 years later. “Wait, Wait, Wait... Hold the phone!! You mean to tell me this underground cable has been buried here for 70 years!!! Not in any sort of conduit, just thrown in a ditch back in the 50’s!!! And it just now decided to fault...”. We both looked at each other and said, "No Way!!" And immediately started looking around for signs of how the service to the house was first installed... Wait we don't have time to play Sherlock Holmes, this customers power is out and the sun is going down quick. Finding the cause of the outage is much easier during the daylight hours, you know that weird thing the sun puts off... light! Helps out big time. :wink:wink: In all honesty, when we arrived at the outage and the fuse was blown, we hope for an easy fix or we will settle for an obvious cause of the outage. Even though testing underground cable is really fun, that quick fix or blatant cause of the outage if preferred... sometimes... Feel free, click on that link or check my last few posts, making things go BOOM is always fun. Every time a fuse blows, or something blows up I can't help but die laughing... It's a Lineman/Man thing I guess

Without any definite sign to what caused the outage, it was time to start trouble shooting. 2-runs of direct buried 25Kv underground cable, an old POS Ranch Runner Transformer, and a pole mounted CSP Transformer (also a POS). Did I mention that the direct buried underground cable is a POS too?? It has no outer protective jacket, it's not put in conduit, and the insulation is a PITA to work with. Maybe the new technologies in the industry have me spoiled?? 😉 OK, enough jibber jabber!! Let's get into it...

A Day With A Lineman

Faulted Cable

I feel I need to clear the air on how old this cable is. The house was initially fed from some overhead wire. We did some Sherlock Holmes-ing and connected the dots. This cable is close to 30 years old and I believe the typical lifespan of this cable is around 20 years. So it looks like this cable has exceeded its lifespan. Whenever this old direct buried cable gets a faults it gets put into the list of old cables that need replaced.

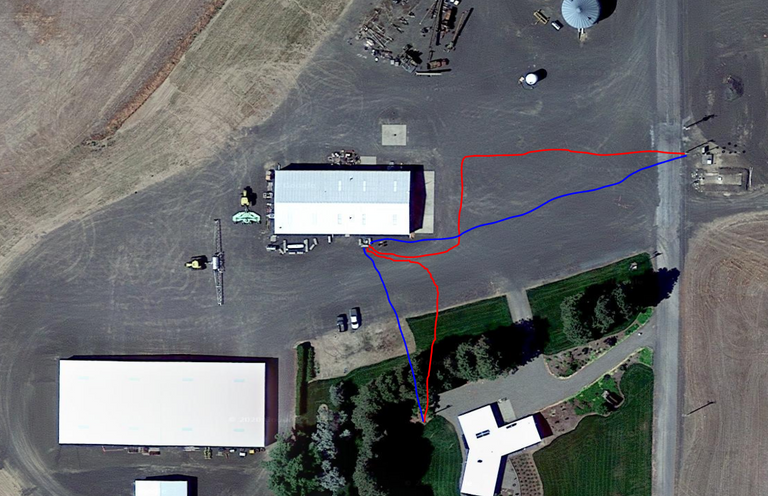

One thing was still really odd about this underground cable install. The route it took to the Ranch Runner transformer and then to the house didn't make too much sense...

Red is the location of the cable - Blue is how we would have ran the cable

There has to be some sort of method to their madness, maybe some waterlines or something were in the way... who knows. Then again it's easy to play Monday morning quarterback. Outage... Ya, back to the Outage... The main fuse that feeds the underground tap was blown. First we visually inspect everything thoroughly. Looking for any signs of arcing and sparking or catastrophic failure. (those are my favorite😉). Use a hotstick and pull the pressure relief valve and give the transformer a little sniff test. Typically if the transformer is bad, you will get a big wiff of a burnt oil smell. With both transformers passing the sniff test, I isolated the overhead CSP transformer at the house and decided to refuse and test the tap. This will test the run of underground cable to the Ranch Runner, the Ranch Runner, and the run of cable to the house transformer.

That fuse blew hard!!! It sent echoes across the countryside... it was awesome!!

We made a call for some help to head to the shop because either way we are either gonna need a transformer or the mini excavator to dig up and repair damaged cable. We try to plan ahead as much as possible without jumping to any major conclusions. We figured by the time the other lineman showed up to the shop we would have this all figured out... hopefully.

After raising the dead with that 20 amp fuse blowing, we began isolating pieces of this tap. First was to get that Ranch Runner Transformer out of the mix and isolate this first run of cable. To do this we removed the cable coming into the transformer and the cable going out to the house. These cables are installed on insulted standoffs in order to isolate the cables or equipment from the system. The cables can be safely energized while on the standoff.

source

source

The cable is plugged into this in order to stand it off. The Cable itself has an elbow spliced on the end of it, which allows us to remove and install cables on various equipment using a hotstick.

25KV Loadbreak Elbow

source

Alright, it's time to test again. With the transformer out of the equation we are going to be testing this first run of cable with a 1 amp fuse. No need to slam home another 20 amp fuse since we are just testing. If something is wrong in this first run of cable the fuse will blow no matter what size. When testing we always close the cutout in from the ground using an extendo hotstick. Please oh Please don't get any ideas!!! These hotsticks are tested at 100,000 volts per foot even while wet. Leave this stuff to the professionals... Lineman.

I know I know, you have seen these before if you have looked at my last posts. I just felt they needed to be included in this post as gifs. The videos didn't turn out too well IMHO

DAAAANG That 1 amp fuse hit hard too. When fuses blow that hard it is a sure sign of a nasty fault. In this case we have bad spot in this first run of underground cable... somewhere in this 500 foot long piece of cable.

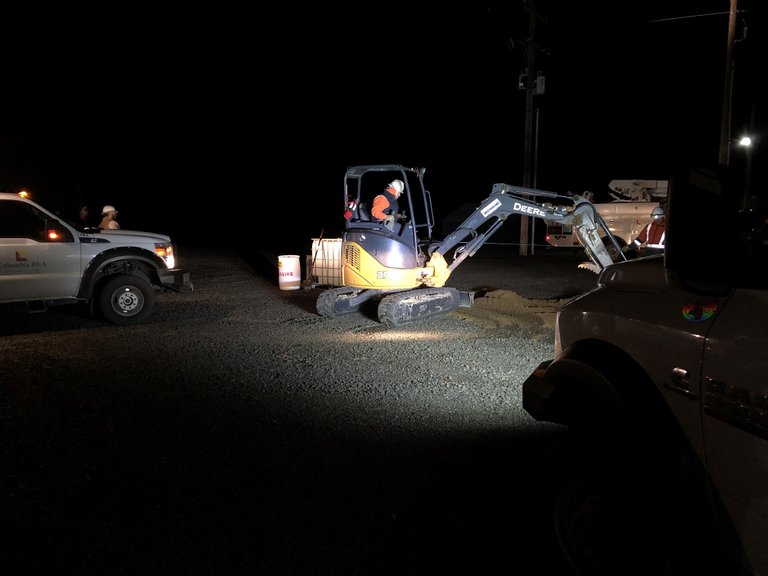

Time to make a quick call to the lineman at the shop. After asking if he combed his hair before he left his house, I told him to grab the mini excavator, the thumper, a couple splice kits and a chunk of underground cable. In the mean time we have to locate this cable and see exactly where it goes. Like I mentioned above, the route of this cable had our heads filled with question marks. We have a bad habit of trying to figure out why things were done a certain way and we tend to get distracted from the task at hand thinking about it.

The cable has been isolated, tested and ground. It's been located so we know the exact path it takes from the pole to the transformer. Now it's time to find out where this fault in the cable is. To do this we have this big box on wheels called a Thumper. What this machine does is apply voltage to the cable until it faults. When the cable faults you can hear a loud thump coming from the ground.

It's powered by the inverter on my truck and it simply hooks onto a ground source and onto the conductor itself. This is the Ranch Runner with the cables in it... lots of room in there huh? Good Greif!! Just trying to remove the cables I thought I was going to break the probe that makes the connection inside the transformer.

sorry it's a little blurry

Once the Thumper is hooked up and everyone is in the clear on both ends, it's time to fire it up and let the Thumper do its thing. Thump!

Every time the needle falls back to 0 that means the cable has faulted and can no longer handle the voltage. The result of the fault is a distinct thumping coming from the ground. Every 3-5 seconds it thumps. Now if it is too quiet and you can crank the Thumper up to get a louder thump. In this case we had a really nice thump going and all we had to do was put our ears to the ground and find out where the thumping is the loudest. Actually by placing your ear on the end of a shovel handle and holding the shovel on the ground, the thumping can easily be narrowed down to a 6-10 foot area. Sometimes when we can't quite narrow down the location of the fault, we will turn the Thumper down so the thumps don't echo so bad. Then using a road cone just the same way as the shovel. Once we get everyone to agree on the location of the fault, it's time to start digging.

The hole needs to be big enough for a couple guys to get in there and work. So once the cable is found, we expose about a 10 foot length and start looking for a bad spot. It's normally pretty easy to find. A hole will be blown in the insulation. So the electricity arcs from the conductor, through the weak spot in the insulation. Little by little until it finally eats away at the insulation enough for the full amount of electricity to reach the ground causing a ground fault.

In this case the bad spot was small enough to where we could cut out the small piece of bad conductor and insulation and just splice it back together. The sleeve used to connect the two pieces together has about a 1 inch long piece in the middle of it that is solid. This allows a little bit of the cable to be cut out and yet they will still fit all the way in the sleeve. You know since we can't pull some slack from any direction. If the spot was big enough to where the sleeve couldn't span the gap then we would cut out a 3-4 foot chunk of the cable and splice in a piece. That method would use two splices instead of just one.

Once the repair is made it's time to energize the cable to ensure that there are no other spots that are bad. We always leave the hole open and the cable exposed. Wouldn't that suck to have to dig it all up again because of another bad spot that was too small to see? Now that the Thumper has been disconnected, protective grounds removed and everything back to normal, it's time to energize the cable. Good thing because my warming fire was getting a little small.

The lights in the house are on and nothing blew up. So all that is left to do is backfill and compact the hole. We always try our best to leave the area better than it was when we got there... at least try to make things look like we were never there.

There you have it another episode of A Day With A Lineman is in the books. I hope this gave you all a little more insight into what goes On when the lights turn Off. Remember, don't attempt to do any of this yourselves. It may seem "easy" but that is only because we have had the proper training and learned the skills it takes to do this sort of thing safely.

Stay Safe Everyone!!

Your Random

Dose of...

Yooo! Long time no see. Merry Christmas Eve.

Hot stick #2. Was that you? Who did that without a face shield? Eh, is that normal to bury a splice instead of setting a box for you guys?

No it wasn’t me, I like to get up in there when I blow fuses. HAHAHA. We are about 30 or so feet away and once you get lined up you duck your head and slam it home. The fuse in contained in a this fiberglass tube. I have seen 120 amp fuses blow without any damage to the door itself.

These splices are made to be direct buried. They are a real PITA to get on and slid over the pressed sleeve. Lots of lube helps to get it on... well that came out kind of weird... so did that?!?!? Wow I am on one. Lol

Thanks for swinging by!! I hope you and your Wife have an amazing Christmas!!

Funniest thing I've read all week.

"grab the mini excavator, the thumper, a couple splice kits and a chunk of underground cable" sounds wicked

We know what we need when we need it. Lol.