How are you all architectural design friends? In the last few days I'm back working on a home window furniture design project which is an order from the local community in my area and in my 3rd window architectural design,this time I am back working on one of the house window designs which is a design that is also much in demand by local people for house windows and shop houses.

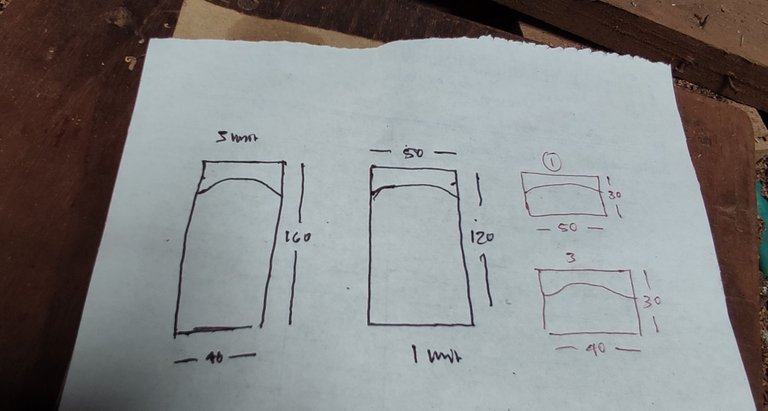

And again, I finished a wooden window project made of meranti wood and this is one of the woods that is in great demand by the public with a characteristic brown color natural of woods and this time I got as many as 3unit orders of windows with the same size, which is 40cm x 160 cm followed by jalousie frames measuring 40cm x 30cm for these windows (3 units) and (1 unit) window size 50cm x 120cm which is also followed by jalousie 50cm x30 cm (1 unit)which is equipped with 5mm translucent black glass and in total 4 units of windows and 4 jalousies in 2 different sizes and this is one of the window sizes that are often used in house construction today.

The materials that I need or that I often use to complete projects such furniture are.

•Mini wood cutting machine.

•Hand drill(to make holes in the wood when installing the pegs) and sit drill(to make holes in the bulkhead of the top and bottom of the window).

•Meter and hammer

•Router machine(for making flowers on the inside corners of windows and making glass holder holes).

•Meter (measuring instrument)and elbow.

•Smoothing machine and.

•Panel machine (to make nipple pegs on frame sets).

•Meranti wood that has been trimmed with a size of 3.5 cm x 6 cm is the main binding material for the window series.

And this is an order and jalousie window design that is equipped with the size and number of windows and jalousies.

And you need to know,,for the thickness and width of the wood frame on the left and right of the windows, we often use wood measuring 6cm x 3.5cm and for the wood frame the width depends on the design order we received and for this one order, the size of the wood frame width of the window we use is wood with size 5cm x 3.5cm (bottom width divider) and 10.5cm x 3.5cm (to form the top window bulkhead).

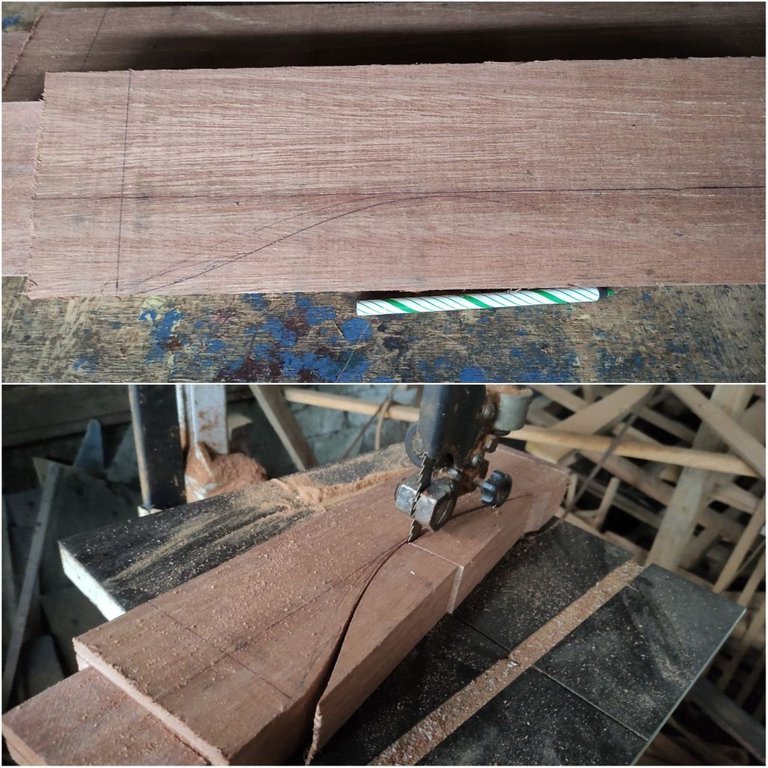

Then to complete the project for the first stage I cut wood for the left and right of the frame from the two windows with different sizes and for windows with a height of 160cm (3 units) here I cut the main frame left and right of the frame with a height of 165cm as many as 6 pieces and for windows that are 120cm high (1 unit) here I cut 2 pieces of wood for the left and right frames of the 125 cm window and also I cut the jalusi window sills with a height of 30cm to 35 cm (8 pieces) from the two windows.

You may ask why on average I give more 5 cm higher than the window height written in the picture?because the 5 cm or I will add 2.5 cm up and 2.5 cm down so that during the insertion process the wooden pegs do not break and when the window is finished ,,the wood that is more than 5 cm will be cut when the window is installed by the window builders home.

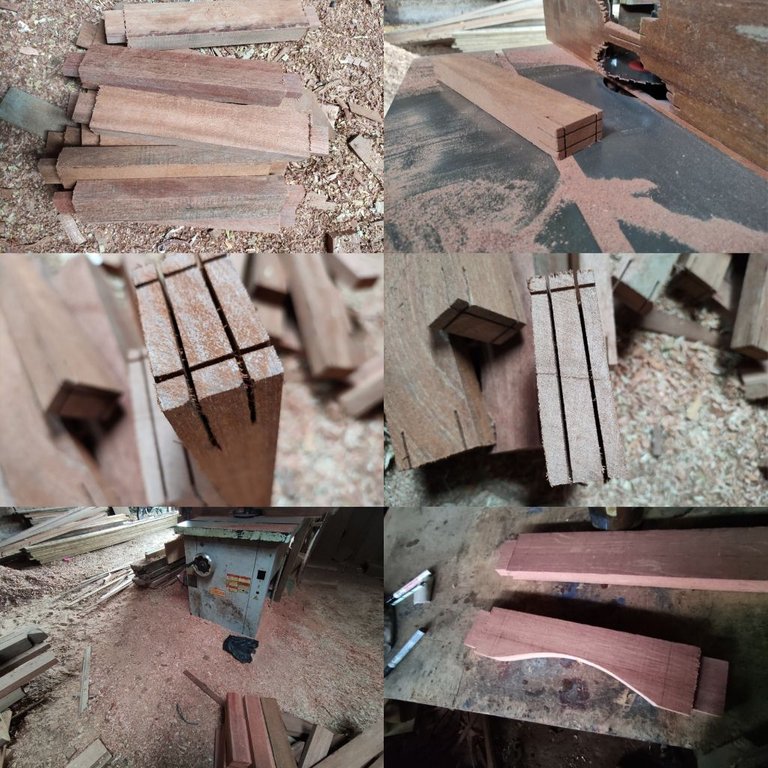

Then I continued by cutting the wood to measure the width of the window and here as I said before, you have to be quite careful in calculating x , - , ÷ , + to get the length of the wood for the top and bottom of the window and also in making the size of the pegs. main nipple chain.

For the upper and lower series of windows and jalousie, the size is 40cm x 160(3 unit) cm and the jalousie is 40 cm x 30 cm(3unit) to get the right result, how to calculate it 40 cm, we subtract the size of the left and right frame of the window (6cm x 2 = 12cm ) means 40cm-12cm = 28cm then we add 3cm+3cm for the left and right pegs, meaning 28cm + 6cm = 34cm for the size of the window screen width of 40cm x160cm and the same for 50cm x 120cm (1 unit) window bulkheads and 50cm x 30 cm (1 unit) jalousie 44cm a total of 4 pieces of bulkhead .

Back to the order design drawing and in the order drawing design, the arch shape is indicated at the top of the window and to make the arch shape, here I used 10.5cm wood to draw the arch shape and cut it using a seated jitsaw machine or a circular saw cutting machine.

To make an arch shape on the wooden bulkhead at the top of the window and the jalousie-julusi, here I draw the arch shape first and for the cutting process you can see in the image below.

Then after the cutting process is complete, I continue with the process of smoothing the former saw blade on the curved shape of the wood by using a grenda machine.

After that, I continued the process of making the main peg nipples on the top and bottom bulkheads of all the windows using a panel machine (wood splitting blade) and for the size of the nipple, the length is 3 cm left and right ,the result is like this.

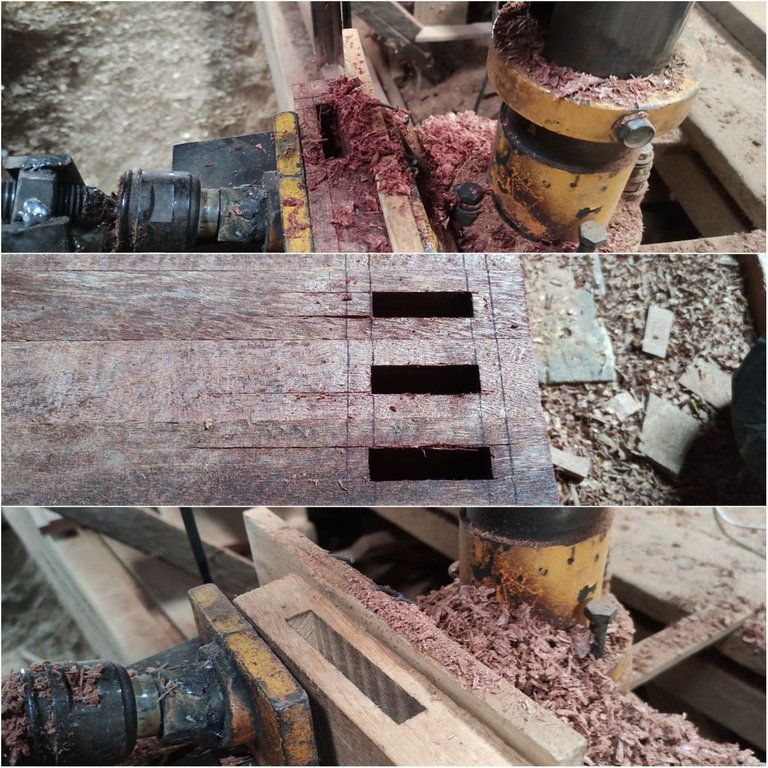

After the process of making the series nipple is complete, I continue by outlining the length of the window on the left and right main frame of the window for the process of drilling the hole for the upper circuit holder under the window with a drill hole depth of 3cm x 1,5cm the length of the bottom hole is 4 cm and the top is 10.5 cm for the assembly bulkhead holderand the manufacturing process is like this.

And now that I have finished all the main assembly materials for windows and jalousies, then I assemble the basic assembly, then I continue the process of planer / trim all parts of the main frame of the front and rear windows using hand shaving machine.

Then for the next stage, giving flowers around the surface of the base circuit in the front and back windows, followed by the process of giving a 5mm glass holder hole with a depth of 1cm.

then, I continued with the process of giving glass to tha window and the jalousie ,and the owner of the order ordered 5mm itam glass for this window and jalousie, the standard glass size from the factory was 152cm x 122cm and the window had a different size,, for the first time I prepared the glass for windows 40cm x 160cm.

And after all the process of installing the glass on the window and the jalousie, I continued with the pressing process and to lock all parts of the wood connection, first I drilled the cocking part of the circuit which I continued by giving pegs made of wood.

Then after the glass installation process, pressing and dumpling processes were completed for all the jalousies, now I continue the process of smoothing the entire front and back surface of the window to smooth the entire wooden surface of the series of windows and after all the window-making processes are complete and this is the result of the architecture design of the window and that jalousie, of two different sizes, namely, 3 units of window size of 40cm x 160 cm and 3 units of jalousie 40cm x 30 cm and also 1 unit of window size of 50cm x 120 cm and also 1 unit of jalousie of 50 cm x 30 cm an order of meranti wood and 5mm black glass which is an order from a villager that I have completed and is ready to use.

I am @deltasteem from aceh, indonesia province and i am an employee of cv funiture in aceh which sells wood and all kinds of building materials and also accept all types of household furniture orders according to your order.

All of these pictures when i was working on that window and jalousie project and all images were taken using a smartphone camera, if you want to enjoy my previous architectural design works, please visit the post link below.

1.Architectural design- simple cafe bar table

2.Architectural design - Wooden tray with natural wood color combination/utilization of wood waste

3.Architectural design - Flower vases / utilization of wood waste.

4.Architectural design-Simple architectural design of my baby crib basket.

5.Architectural design-Table simple the combination of natural wood colors and classic table tops

6.Architectural design- Shophouse frame jalousie

7.simple-minimalist-mini-wall-shelf-architectural-design-to-decorate-your-home-room

8.architectural-design-of-the-ventilation-jalousie - part 1

9.architectural-design-of-windows-house -part 1

10.interior-design-architecture-simple-makeup-mirror-frame.

11.architectural-design-simple-minimalist-wooden-window -part 2

The rewards earned on this comment will go directly to the person sharing the post on Twitter as long as they are registered with @poshtoken. Sign up at https://hiveposh.com.

Thank you for sharing this amazing post on HIVE!

non-profit curation initiative!Your content got selected by our fellow curator @priyanarc & you just received a little thank you via an upvote from our

You will be featured in one of our recurring curation compilations and on our pinterest boards! Both are aiming to offer you a stage to widen your audience within and outside of the DIY scene of hive.

Join the official DIYHub community on HIVE and show us more of your amazing work and feel free to connect with us and other DIYers via our discord server: https://discord.gg/mY5uCfQ !

If you want to support our goal to motivate other DIY/art/music/homesteading/... creators just delegate to us and earn 100% of your curation rewards!

Stay creative & hive on!

thanks @priyanarc I hope you and your family are always healthy there and also my greetings, I hope the entire team @diyhub who works there are always healthy :)

Great work as always my friend. Good evening!

good evening again friends, thank you as usual this is my job :)

You're welcome (^_^)

Impressive architectural production work, as always! I have the impression that this specific commission seems to be more meticulous than your previous window frames. I think it's all because of some curves in the profile, isn't it? How long did it take you to complete this entire project order @deltasteem?

of course @storiesoferne the design curve this one gives the impression of luxury on the windows, I did it in 2 days,and this design window will look more luxurious if it is made in a size of 30cm x160cm or 170cm high and I think this window with this size is quite beautiful when used in minimalist home buildings.

And maybe you're wondering what wood is behind where I noticed the window and that wood is often seen in some of my posts,

it is a bar caffe table sheet that is in the process of being worked on and I have postponed the manufacturing process because the owner has not made the slightest payment.

Oh yeah, with all the available power tools, raw materials, and professional expertise at your immediate disposal, these window frames would not take long to fabricate. That curved profile on the project definitely adds a sense of class to it. As usual, thank you for this incredible piece of work. Congrats @deltasteem! 😊

@storiesoferne,you're welcome and greetings design architecture :)

My dad and I have a small workshop at my home town, and we have been doing small DIY furniture for our home. Your posts are really inspiring to me. Keep up the great work.

Thanks buddy, and it's a fun activity isn't it? and furniture is my daily work ;)

Architecture Brew #60. More power!Congratulations @deltasteem! We're delighted to specially curate your awesome publication and award it RUNNER-UP in

Thank you for subscribing to Architecture+Design, an OCD incubated community on the Hive blockchain.

and I am always ready to share tips in architectural + design furniture publications to liven up their enthusiasm for learning in this useful matter.thanks @aplusd for giving me space to publish my content that might be useful for our friends who want to learn how we work in window furniture and others.

With utmost pleasure @deltasteem. We are truly impressed by your incredible work. Your amazing content deserves to be recognized in our beloved community. Cheers! 😀