A Flame-Side Chat with Prof Matt Bochman

Hello, fellow brew enthusiasts,

This week, we are having a flame-side chat with Prof Matt Bochman, leading author of a paper entitled: “Primary souring: a novel bacteria-free method for sour beer production”. Matt is an Associate Professor in the Department of Molecular & Cellular Biochemistry at Indiana University. You can find his lab webpage here.

I described his paper here, and it gives me great pleasure to report on my discussion behind the scenes in this post.

(Left to right) Cody Rogers, Matt Bochman, and Caleb Staton toasting a successful science-brewery collaboration at the Upland Brewing Company. Image credit: James Brosher, IU Communications

We previously described this paper, which in a nutshell, helped identify hetero-fermentative yeast strains, able to produce lactic acids. Here, we will talk about what led to the development of the primary souring approach, what it took to get there, and what we can learn from it. Importantly, his work has inspired him to create his own company (wild pitch yeast; more on that below). You can more information on his commercial services here.

Edgar: What sparked your interest in wild yeasts, and more specifically, those that can sour beer?

Matt: I'm a yeast guy in general but not specifically wild yeasts. I've been working in research labs in one capacity or another since 2001, and yeasts have been model organisms used to ask and answer scientific questions in all of those labs. They're great organisms for genetics, molecular biology, biochemistry, cell biology, etc. At around the same time that I fell in love with research, I was getting interested in the budding craft beer scene in the US and started homebrewing. By the time I started my own lab (2013), I was hooked on both yeast and fermentation, so I reached out to local brewers to offer my help with the yeasty end of things if they ever needed it.

Eventually, I met Rob Caputo, who was the head brewer at the Flat12 Bierwerks in Indianapolis at the time, and he wanted to make the all-Indiana beer. Farmers had started to grow hops in the state, we had barley grown and malted here, it wasn't hard to get Indiana water - the missing ingredient was local yeast. That led to us developing a yeast hunting protocol, collecting and characterizing our first 20 or so strains, and making some fun one-off, all-local beers for people to try. Being a science nerd, I wondered what else Mother Nature had out there just waiting to be found, and one of the big surprises was hetero-fermentative yeasts. We didn't specifically set out to find them; we lucked into them as part of our larger wild yeast collection. Being spoiled by the delicious sour beers that the Upland Brewing Company makes locally is what really got me to focus on the "lacto-yeast" though.

Edgar: In your paper, you state that the identification and use of novel yeasts lag behind in brewing. Apart from the influence of brew yeast suppliers, do you have any opinion as to why wild yeast uptake has been relatively slow?

Matt: Brewers are taught early to keep everything as clean and sanitized as possible because wild microbes can easily ruin their hard work. Getting them to realize that they can use non-standard bugs in their beers then becomes an uphill battle. If you can brew with California ale yeast, a Belgian ale strain, and a hefeweizen strain without cross-contaminating, then you've got good enough cleaning procedures to use just about any yeast strain. In the hop-crazy world of brewing, many people also simply don't know that yeast can supply 50% or more of the flavor and aromatics to a beer that isn't heavily hopped. There are neutral, fruity, bitter, and funky yeasts just like there are many varieties of hops. Use all the tools available!

Edgar: Many (lager) yeasts are infertile and hybrids. How do wild strains compare when used in brewing? Do they sporulate? Are they more difficult to maintain?

Matt: Wild strains are quite different from commercially available domesticated lager and ale strains. People think they're unpredictable, but that's just because we haven't been brewing with them for decades and know all of their ins and outs. We propagate and store wild yeasts in the same way that we do standard brewing strains, and if anything, they grow faster than their domesticated cousins. When it comes to fermentation though, it's a mixed bag. There's a wide range of attenuation and flocculation levels, optimal fermentation temperatures are likely to be different, etc. Some of these strains are known to sporulate, and spores may actually be what we're reviving in the lab after yeast hunting. With somewhere between one hundred thousand and one million yeasts predicted to be out there, there's no one-size-fits-all description of wild yeasts though.

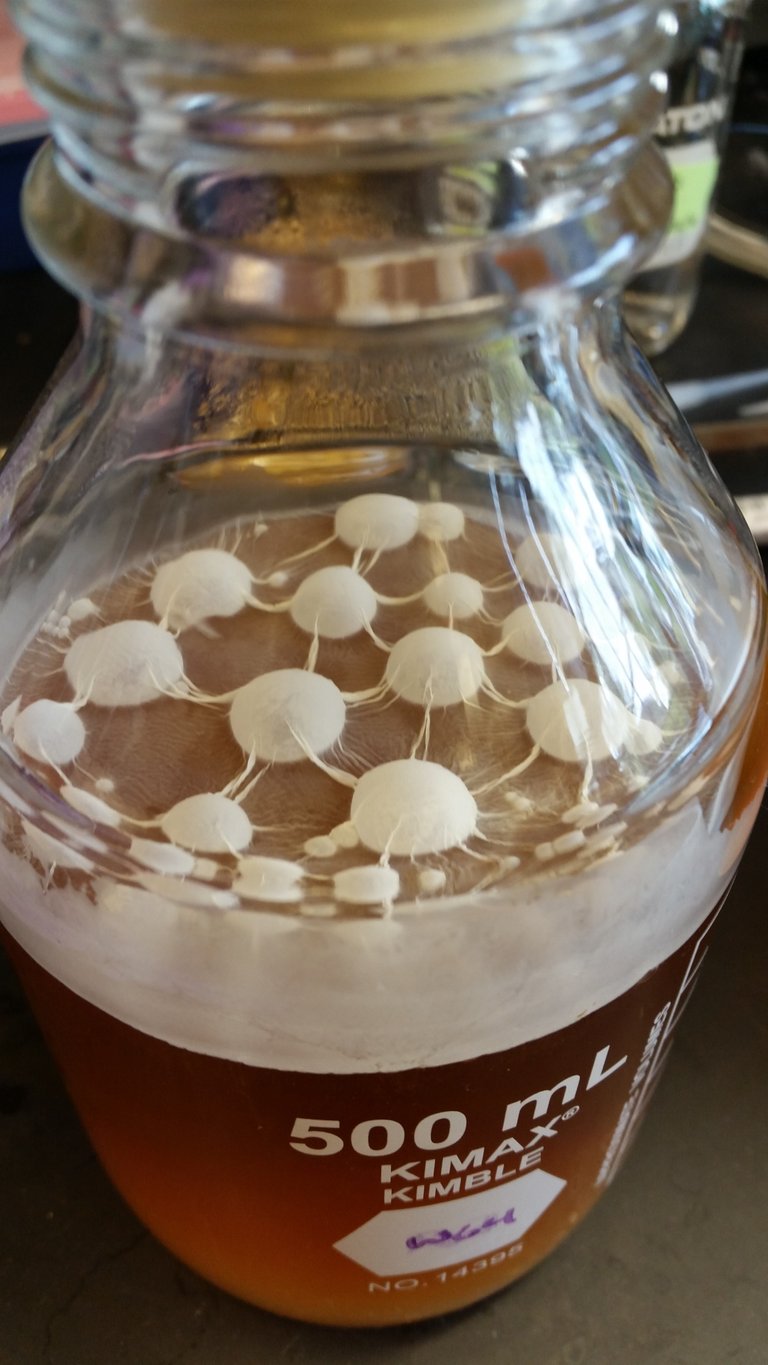

A wild yeast pellicle growing atop a mini-fermentor full of blonde ale wort in the Bochman Lab. Image credit: Matthew L. Bochman

Edgar: What, in your opinion, are the best places to look for wild yeast, suited for brewing?

Matt: All wild yeasts are going to be found where there's an abundance of sugar, so people generally start by collecting things like fruits, berries, vegetables, and running tree sap. Sugars polymerize into lots of complex things like woody biomass though, so tree bark, decaying wood, and soil are incredibly rich sources of wild yeasts too. We tend to have the best luck finding brew-worthy yeasts on tree bark, which may hint at the origins of commercial yeasts on wooden vessels and tools used to brew beer before stainless steel became the go-to material.

Edgar: Could you briefly elaborate on how you isolate yeast from bark?

Matt: We collect small pieces of tree bark (postage-stamp-sized is plenty) into plastic zip-type bags, which are essentially sterile on the inside. Back in the lab, we then transfer those samples to test tubes containing 5 mL of a medium that’s composed of 1% yeast extract, 2% peptone, 8% dextrose, 5% ethanol, and some antibiotics. The high sugar level helps to select for osmo-tolerant yeasts, and the ethanol selects for ethanol tolerant yeasts. The sugar also selects against some molds, and the ethanol and antibiotics kill nearly all bacteria. We then incubate the tubes with aeration (on a roller drum or in a shaker) and wait 1-3 days for the cultures to show signs of growth by becoming turbid. We then streak out small volumes of the turbid cultures onto Petri plates (generally WLN agar) to isolate individual colonies of any and all strains present. It really boils down to classic microbiology and single colony purification. A homebrewer can mimic this setup at home using weak, hopped wort (gravity = 1.040) supplemented with some vodka to get started.

Edgar: What does the perfect (imaginary if needed) wild yeast strain look like?

Matt: The perfect wild yeast depends on what you want to ferment. If you want to make a killer beer, you want a strain that eats maltose (and perhaps nibbles some of the longer-chain malt sugars), make 5-10% ethanol, attenuates well, flocculates well, tolerates a pH range of 4-5.5, and ferments fast at your ambient temperature. If you want a good wine yeast, you don't care about maltose but want a strain that can tolerate more osmotic stress (high sugar content) and yields even more ethanol. In some sense, all wild yeasts are perfect; we just haven't found the perfect use for them yet.

Edgar: How do you see this work advance the efforts of (small) breweries and home brewers? Or how can we better stimulate wild yeast uptake?

Matt: I know brewers - professional and homebrewers alike - that struggle with making sours for various reasons. Our hope is that lacto-yeasts can make the process more approachable for everyone. The market seems to agree, and that's why Lallemand is selling the Philly Sour yeast now. It's not one of ours but a lacto-yeast nonetheless. More broadly, brewers are also learning to love kveik yeasts, which aren't quite wild strains but still new to most of them. As more and more people begin to experiment with these non-standard strains and mixed culture fermentations, the stigma or fear of using wild yeasts will hopefully go away. Honestly, I hope the same thing happens with GMO yeasts. There's a world of possibilities there too.

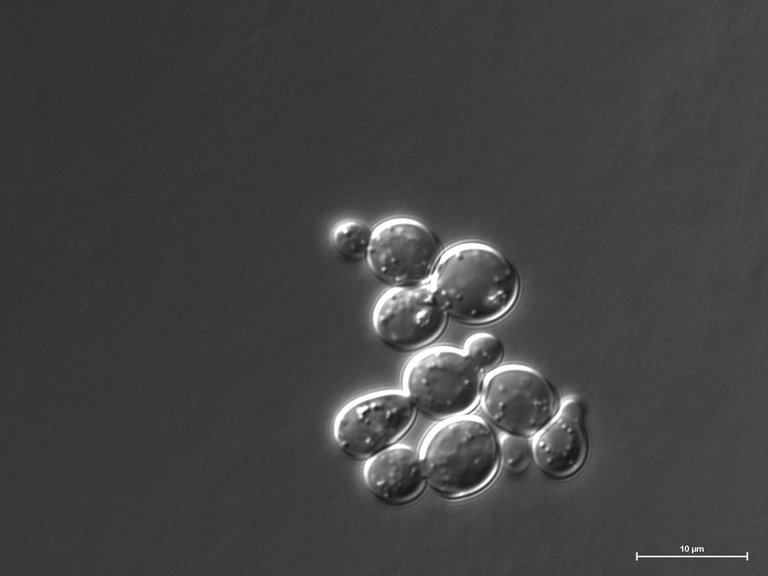

Differential interference contrast (DIC) micrograph of YH38 cells, a strain of Saccharomyces paradoxus isolated from the bark of a chestnut oak right outside of Simon Hall on the Indiana University campus. Image credit: David G. Nickens.

Edgar: What was the biggest hurdle or bottleneck in your research?

Matt: Funding! I would love to do more fermentation research, but there aren't many sources of funding for such projects. Specific to our yeast hunting though, the biggest bottleneck is fermentation. It's easy to find ethanol-tolerant wild strains using the protocol in our Food Microbiology paper. We've got ~400 in the freezer now, but there's nothing stopping us from collecting 4000 or 4 million. The hard part is figuring out if they would be any good for making beer, and for that, you have to brew with them. We've brewed with each of our 400 strains once and tasted each beer, but that's a slow process.

Edgar: Are you planning or are your strains available to (home) brewers that wish to use them for brewing?

Matt: The original idea that Rob Caputo and I had was to start a yeast lab to not only offer yeast and yeast hunting services to brewers but also more typical lab services to breweries that don’t have their own in-house QA/QC labs. We’ve jumped through the hoops to create an LLC called Wild Pitch Yeast, but the logistics of starting a business like this while all of the stakeholders have other, intense, full-time jobs has us in a state of limbo. We have sold pitches of yeast to brewers all across America but at a very small scale. Short of a cash infusion or partnership with an existing yeast lab, we don’t currently have a way to scale up and expand our reach. If anyone is interested in that partnership though, please reach out to us at [email protected]!

Edgar: What is the next important but yet open question that you are now addressing from your research?

Matt: I'm a science geek, so I'm interested in all of the questions. How and why are the lacto-yeasts making lactic acid while nearly all other yeast strains examined don't? Can we optimize brewing conditions for these strains to make them more competitive with traditional brewing yeasts? Can we push things even further to make industrial levels of lactic acid, which can then be turned into polylactic acid (PLA), a biodegradable plastic? The list goes on and on.

Edgar: Thank you so much for a very stimulating flame-side chat. I am sure many of us will be sampling local bark to look for some delicious beer yeasts!

Edgar, The Beerologist.

Edgar Huitema is a Scientist, Brewer & Scientific Consultant at ExtrAnalytics. Subscribe to my free newsletter to get the latest advances in science. Contact me if you wish to discuss your needs and our research.

Support us

Recently, I learned that the average price of a six-pack of (US) craft beer is $12. For only $5 per month (about 3 bottles of craft beer), you support our mission: To keep you up to date with the latest brew research. Check out the additional benefits paid membership brings and give us a go!

Congratulations @huitemae!

You raised your level and are now a Minnow!

Check out the last post from @hivebuzz: