Concrete that heals itself? How does it function? What impact will it have on the industry?

Photo Source

The most widely used construction material on the planet is concrete. It can be found in large swaths of city pavements, river bridges, and the world's tallest skyscrapers. However, this tough material has a flaw: it's prone to catastrophic cracking, which costs tens of billions of dollars to fix each year.

If there is one flaw in concrete, it is that it has a low tensile strength, necessitating the addition of steel to make reinforced concrete. As a result, the steel must be protected from corrosion by the concrete. However, if the concrete cracks, it creates a pathway for harmful substances like chlorides, carbon dioxide, and eventually oxygen and water to reach the reinforcing steel, causing corrosion, rust, and eventually concrete destruction.

But what if we could avoid that problem, by creating concrete that heals itself?

Photo Source

This concept isn't as absurd as it may appear. It all comes down to knowing how concrete forms and how to use that knowledge to our advantage. Concrete is made up of aggregates (coarse stone and sand particles) mixed with cement (a powdered mixture of clay and limestone). When water is added to this mixture, the cement forms a paste that coats the aggregates and hardens quickly due to a chemical reaction known as hydration.

The resulting material eventually becomes strong enough to support buildings that rise hundreds of meters into the sky. While people have been making cement for over 4,000 years using a variety of recipes, concrete has a surprisingly short lifespan. Natural processes such as concrete shrinkage, excessive freezing and thawing, and heavy loads can cause cracking after 20 to 30 years.

Photo Source

It's not just big cracks that are dangerous; small cracks can be just as dangerous. Around steel reinforcements, concrete is frequently used as a secondary support. Even small cracks in this concrete can channel water, oxygen, and carbon dioxide into the steel, corroding it and causing it to collapse. Detecting these problems before they lead to catastrophe on structures like bridges and highways that are constantly in use becomes a huge and costly challenge. However, failing to do so would jeopardize the lives of thousands of people.

How does it function?

Photo Source

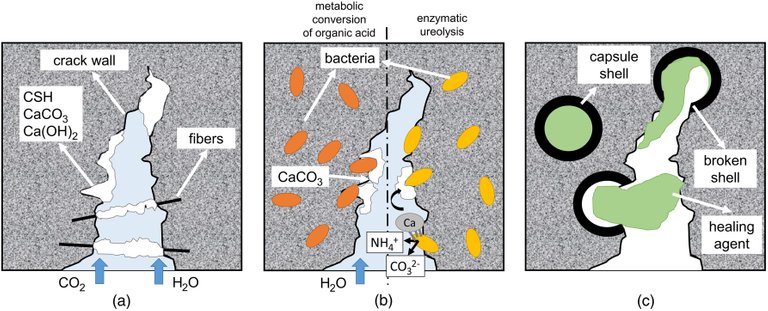

Fortunately, we're already experimenting with ways to get this material to self-heal. Some of these ideas are influenced by concrete's natural self-healing properties. Water hydrates the calcium oxide in the concrete when it enters these tiny cracks. When the calcium hydroxide reacts with carbon dioxide in the air, a process known as autogenous healing begins, in which microscopic calcium carbonate crystals form and gradually fill the gap.

Photo Source

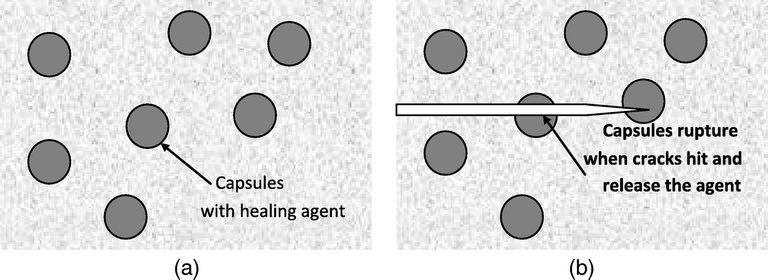

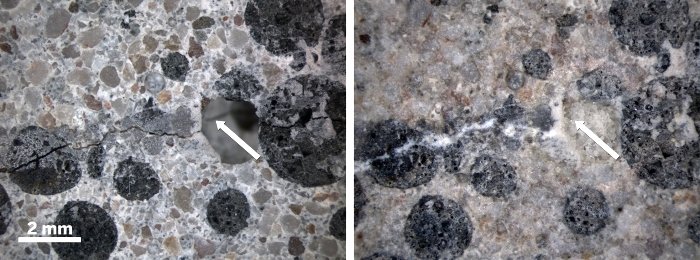

Unfortunately, these crystals can only heal cracks smaller than 0.3mm in diameter. By incorporating hidden glue into the concrete mix, material scientists have discovered a way to heal cracks up to twice that size. When we add adhesive-filled fibers and tubes to the mix, they will snap open when a crack appears, releasing their sticky contents and filling the gap.

However, adhesive chemicals often behave differently than concrete, and these adhesives can cause even worse cracks over time. Giving concrete the tools to help itself may be the best way to heal large cracks. Scientists have discovered that some bacteria and fungi, including the calcium carbonate found in autogenous healing, can produce minerals.

Photo Source

These bacterial or fungal spores are mixed in with nutrients in experimental concrete blends, where they could remain dormant for hundreds of years. When cracks appear in the concrete and water seeps in, the spores germinate, grow, and consume the nutrient soup that surrounds them, altering their local environment and allowing calcium carbonate to grow.

These crystals gradually fill in the gaps, and the hard-working microbes can completely repair cracks up to almost 1mm wide after three weeks. When the cracks close, the bacteria or fungi produce spores and become dormant, ready to begin a new cycle of self-healing when new cracks appear.

Impact in the Industry

Photo Source

Despite extensive research, we still have a long way to go before incorporating this technique into global concrete production. However, these spores have a huge potential for making concrete more durable and long-lasting, potentially lowering the financial and environmental costs of concrete production. These microorganisms may eventually force us to reconsider how we think about cities, bringing our otherwise lifeless concrete jungles to life.

We could eliminate the need for repairs if we could develop self-healing concrete, which would save a lot of money. However, there would be an environmental benefit – remember how much concrete we make? The amount of cement we need to make that concrete contributes between 5 and 7% of carbon dioxide emissions. As a result, any concrete that we don't need reduces the industry's CO2 emissions.

References

https://www.lorman.com/resources/what-is-self-healing-concrete-17376

https://www.giatecscientific.com/education/self-healing-concrete-embedding-self-activating-bacteria/

https://www.materialsperformance.com/articles/material-selection-design/2018/09/new-bacterial-process-developed-to-heal-concrete

https://www.biobasedpress.eu/2018/02/self-healing-concrete/

I first learned about self-healing concretes a while back but never read it details like this. I'm concerned about some of your images though. Are they all from free sources?

Thanks for dropping by sir :))

Asi es amigo mas cuando la cosntruccion se encuentra serca de las vias del tren o de alguna avenida importante, por el movimiento y vibracion, tambien se agrietan constantemente, saludos.

TYSM ^-^