Finally after a hard day at work and an attempt at a healthy dinner, I have some time to finally talk about my Saturday brew: The Hop & Liefde clone.

As I am writing this, I can hear the constant bubbling of the fermenter which is a good sign of a healthy brew. My second brew was a complete disaster and the fermentation was so slow I seldom heard any bubbling at all. So the first 12 hours of fermenting are always tense for me, as I carry at the back of my mind the feeling that it may all go down the drain again. But those fears are all but gone as this brew is fermenting like a champ.

Mido took up some of the milling work(out), after all, we men need strong beer arms to lift our beer crates.So let's rewind about 6 hours to the first step, which at this point has become a classic of every brew at my place, milling the barley on the ironing board. I feel like I should explain my extravagant preference for an ironing board as my milling table, but the answer is simple: it was a temporary (probably permanent) solution to a problem of not being able to fix the mill on any other table in the house. If you can't help but hear a voice saying #HOMEBREW in the back your mind right now, don't worry, this is working as intended.

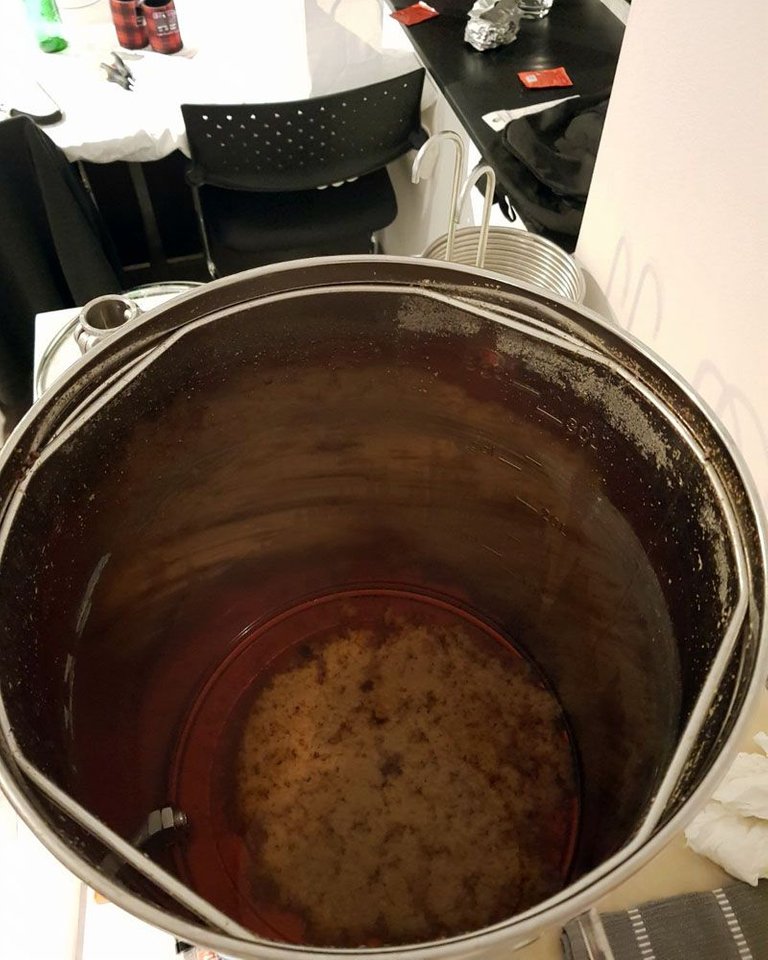

After nearly an hour of grinding all the barley, we had 4 kilos of Pilsner and 1 kilo of Caramel malts ready to go. First in was the Pilsner.

After pouring the Pilsner malt, the Caramel malt was next. This one will help achieve a nice golden color to the beer, as well as more toasted dry notes. The objective was a color of 23 EBC, although I'll be honest, I don't have the qualification yet for measuring this, it is something I still have to learn. Beersmith 2 calculated that this ratio of grain was the right amount to achieve this color, so I trust it for now. You can't just pour in all of the barley at once, since big lumps could form and impact your efficiency. It's like making porridge, you need to pour the grain slowly and mix well. Since this part requires some pro cooking skills, I recruited Chef @exyle for the job of stirring.

Mashing profile was 20 min rest at 60C and 60 min rest a 64C and mash out at 78C. The objective was the produce a wort with dry but malty flavor profile and thick foam. We'll see if I succeeded.

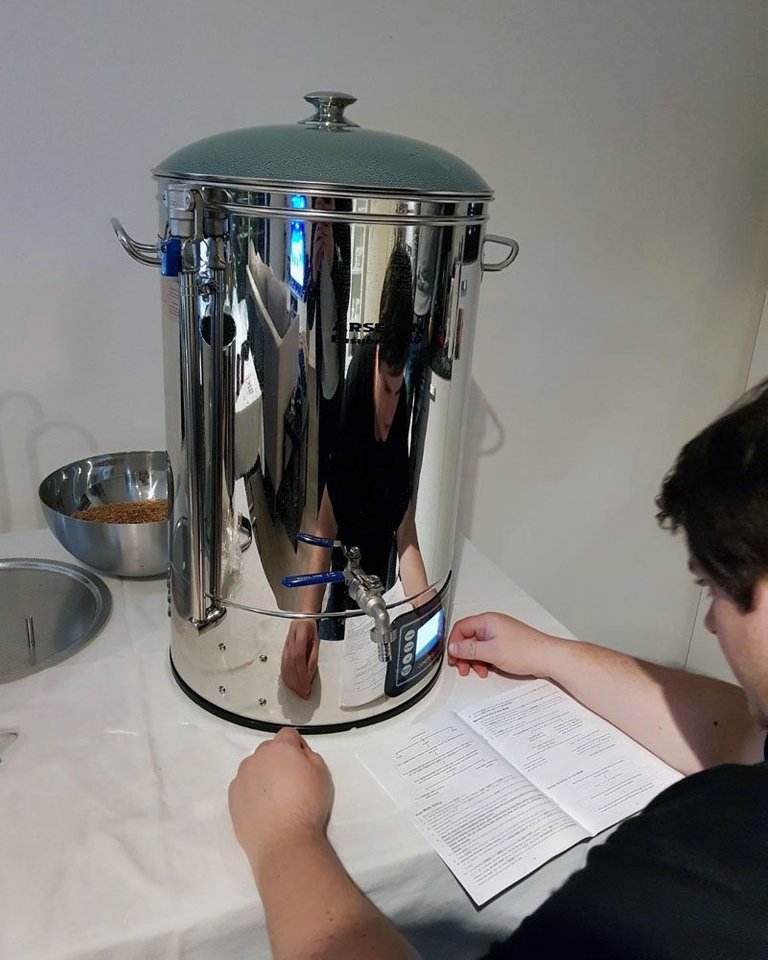

Since it was only the second time I was using my Easybrew 30, there was still a lot of manual reading to be done in order to get the settings just right. I still have a hard time with the sparging stage, as in my opinion, it takes a bit too long while the wort is sitting at 78C. For this brew I sparged with about 6l of water, but I think on my next try I will use less so the wort goes to boil sooner.

After mashing was done, removing the filter and the grain was pretty tough, as my table + kettle setup was too tall and I had to climb on a ladder to remove the 8-10 kg of wet grain. I always feel bad about throwing this away, as I know there is some cow out there in the world who would absolutely love to munch on these. So if you are a bovine and you are out there looking for some delicious barley to eat, I got you covered.

I boiled the wort for 75 minutes, adding 80g of Saaz pellets at 60 min and another 80g at 30 min. According to Beersmith 2, this should yield around 57 EBC of bitterness. I used hop bags for this stage, as I like to keep the trub to a minimum, but I noticed that 80g of hops in one single bag was a tad too much, as they bloated to the size of a grapefruit. Next time, I think I will fill each hop bag with a maximum of 40g of pellets.

After boiling was done, I added some Irish Moss for coagulation, and did my favorite part of the entire brew, the Whirlpool. I managed to keep the wort loss at a minimal thanks to a compact Trub as a result of the Irish Moss.

My objective was to have a final gravity of 1.045-1046, however I think I went a tad too far with the water and ended up with a FG of 1.044, which will likely produce a beer of about 4.5% abv, not quite the 4.8% I was hoping for but still reasonable for an American Pale Ale. I tested the FG by cooling the wort to 25C as fast as I could on running cold water.

After I was satisfied with the FG value (more or less) it was time to cool the wort, for this, I hooked up the heat exchanger to the tap water which was quite cold due to it being winter in the Netherlands. This helped me cool the beer from 90C to 21C in about 20 minutes. Wish I could cool down the nerves of my girlfriend that fast when she's upset at me.

With the wort cool, it was time to pitch the yeast. I used Safale US-05, this was the same used on my first ever brew which produced a very delicious single malt single hop APA. I can't go wrong with this. The description of Hop & Liefde says that it uses top fermenting yeast, I didn't bother to dig further to find out which, because I can't really convince myself choose another yeast for this brew after the US-05 showed such great results last time.

I let the US-05 hydrate in wort at 21C for half an hour before pitching it in the fermentation tank.

Phew... Time to close the fermenter and wait for those tense 12 first hours, which is when the tank goes from silent to bubbling away joyfully. Job Done!

Except not... after 6 hours of brewing, when you finally think that you can crash in the couch and just enjoy some rest, nope.. you have to clean up EVERYTHING, and cleaner than anything else you are accustomed to. Beer making equipment has to be cleaner than a surgery room.

It's a good thing for my friends that they are such great photographers, this way they can focus on taking pictures rather than helping me clean up.

I kid. I can't complain, without them it would not be possible to post such good pictures of the brewing, so thanks Mido and thanks @exyle, you made this brew all the more special!

I hope you liked this post, I have also made a bunch of videos which I will begin to post using D-Tube, just have to figure out the app a little more. In about two weeks time I will bottle this bad boy, so I look forward to sharing more pictures of this brew in its final stages.

Thanks for reading and see you next time.

Cheers!

Very good post. My dream is to have my own beer.

thanks! It's never too late to start!

Great article! I use the Brewer's Edge Mash and Boil, a very similar unit. I enjoyed viewing your process! Thanks for sharing, looks delicious.

You have a new follower!

Thanks @seahawksfan, I will enjoy checking out your posts from your brewing sessions as well. Consider yourself followed!

Very interesting post.

Thank you, this blog is intended to share all my experiences as progressively learn to homebrew. Hope you enjoy the content!

It was fun man, although besides grinding and stirring I did not do much :). You are a good at this man. The equipment you have is so pro. Can't wait to taste the beer.

Thanks man you were very helpful don't worry. Although I did some research and I will need to dry hop this for about 15 days to get the perfect aroma so you're gonna have to wait a bit before you can take your beer home hehe.

I'm so curious, wouldn't mind tasting it hehe that looks so pro, you were born for this!

I'm sure you will try a lot of it since most of this batch is going to @exyle!

Fantastic, your own beer!!! Do you have a name for it?

Good point @s3rg3, I guess I will call this one Hop & Gratitude since it's the payment back for my friends @exyle and Mido who believed in the brewing project and help me raise the funds to buy it!

This was an excellent post, very interesting! I am a homebrewer too! I think I have around 30-35 brews behind me. Home brewing is a lot of fun but as you wrote, the cleaning sucks! I will follow you and if you are interested, I have done a couple of blogs about home brewing on my channel! :)

Thank you and I am now following your blog also! Great content!

,,,,,,,,,,

I'm curious, I want to prove it!

you have a new follower, I wish you luck, I like your publication .. I hope you like to follow me @fabrews