After successful implementation of the largest in the world combustor created for processing waste made by rocket engine of Buran space ship, Anatoly Papusha together with other specialists took part in series developments in the field of energy and metallurgy. Their experience in the field of aerospace and deep understanding of combustion process came into play. The result of these works was new developments that were patented and some of the participants got their academic degrees. Here the list of most important patents that were gained in period of 1980-1990’s:

№ 1034755“Method of neutralization of nitrogen oxides of hydrocarbon fuel high-temperature combustion products”(1978-1983)

№ 937896 “Method of neutralization of nitrogen oxides and equipment for its implementation” (1980-1982)

№ 996797”Equipment for examination of method of harmful waste and testing measurements and control facilities of parameters in neutralized gas stream” (1983)

№ 1229521 “Method of fuel-oxidizing compound ratio regulation in multi-zone unit heater”(1984-1986)

№ 1364639“Method of Martin furnace worming”(1985-1988)

№ 1405033 “Gas pressure regulating equipment”(1986-1988)

№ 1710793 “Exhaust gas purification equipment”(1989-1992)

№ 1726801 “Secondary air feeder”(1990-1992)

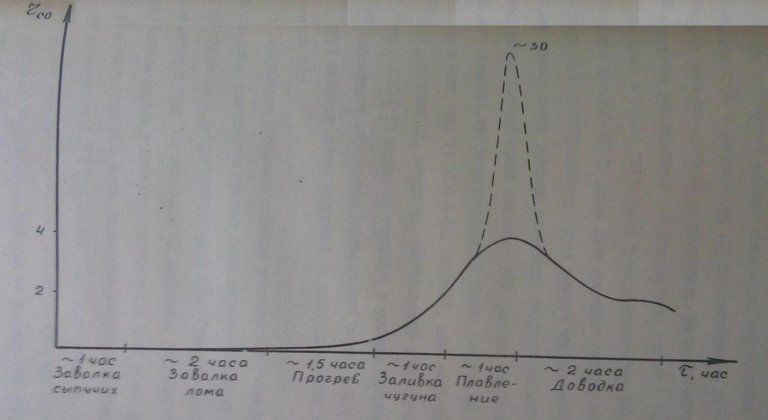

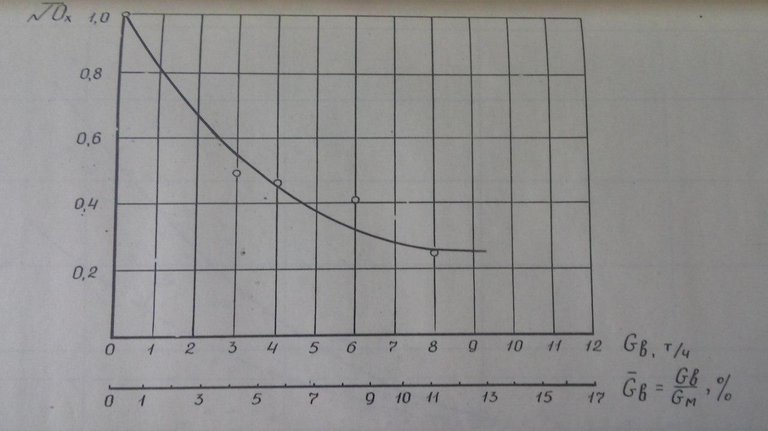

Those developments were implemented on one of the biggest in Europe Martin furnace №6 of capability of 900 tons in Mariupol (USSR, Ukraine). Significant reduction of CO and NOx emission was reached in real production processes (pic.1). In addition, the developments were implemented on Kashirskaya state regional power plant, Moscow region, boiler TGMP-314 with a capacity of 300 MW where significant reduction of NOx emission was also reached (Pic. 2).

Those developments were implemented on one of the biggest in Europe Martin furnace №6 of capability of 900 tons in Mariupol (USSR, Ukraine). Significant reduction of CO and NOx emission was reached in real production processes (pic.1). In addition, the developments were implemented on Kashirskaya state regional power plant, Moscow region, boiler TGMP-314 with a capacity of 300 MW where significant reduction of NOx emission was also reached (Pic. 2).

Pic. 1. Changes of CO concentration in flue gas of Martin furnace in different phases of production process.

Pic. 2. Changes of relative concentration nitrogen oxide in relation to amount of water injected into boiler TGMP-314

Participating in those projects A. Papusha was working on his own development that was later patented – the Russian Federation patent № 2005519 “Method of neutralization of high toxic substances and equipment for this purpose”, 15.01.1994

After many years of research and development, this technology was listed in the United Nations “Survey of Currently Available Non-Incineration PCB Destruction Technologies” (First Issue, August 2000) under the original name of “Papusha Rocket Technology (PRT)”.

Industrial introduction was held on dioxin containing dielectric oil neutralization industrial estate based on one of the biggest in Europe metallurgical complex “Severstal”, Cherepovets. From 1999 to 2004 132 tons of “sovtol-10 ”had been utilized (I hazard class, under the jurisdiction of Stockholm Convention on Persistent Organic Pollutants). The work got the I.P. Bardin prize in 2000.

The next stage was implementation of the technology on the 40 foot container mobile complex in Shykhany, Saratov region, in 2002-2005. Here, 37 prepared substances (chlorum-, fluorine-, sulfur-, phosphorus-based) were processed with the record-high level of environmental safety - 99,9999 %.

Then, in consideration with rising interest to the technology from abroad, the technology was patent-protected in a number of countries:

“Thermo-chemical method of neutralization of high-toxic substances”.

Ukraine, patent № 83134, 10.06.2008

Republic of Belarus, patent № 11790, 28.01.2009

India, patent № 239682, 30.03.2010

People's Republic of China, patent № ZL200580010594.3, 08.12.2010

On the basis of these patents and the method of transonic combustion A. I. Papusha in cooperation with Doctor of Chemistry S.D. Varfolomeev, got patent of the Russian Federation № 2550164 “Technique of natural gas production from gas-hydrate and equipment for its implementation”, 07.04.2015.