A bra that fits exactly, is still an exception to the rule. I would like to put a very interesting woman in the spotlight. Lidewij van Twillert designs tailor-made bras with 3D bodyscans.

The design of a bra is not good. The lingerie is too tight, the straps cut or the clasp itches. Little has changed since the first bra. In 1910 the American publisher and author Caresse Crosby found no suitable corset. By cutting a handkerchief, she had invented the bra by accident. It took another twenty years for the bra to be fitted with a underwire to support the breasts. And the latest innovation - the seamless, pre-formed bras with foam - dates back some twenty years ago. That was mainly an aesthetic procedure. The wearing comfort did not change.

During my industrial design studies at Delft University of Technology, I wanted to do something with fashion. After a workshop in 3D body sciences, I started thinking about which item of clothing really needs to fit perfectly. Those are bras. I started working on that. - Lidewij van Twillert

Her first bra, which she designed as a graduation project, was for the lead actress of the musical Cabaret. The musical is set in the 1930s. That is why she immersed herself in the fashion of that time. With that vintage style in mind, she now designs the custom made bras in her company Mesh Lingerie.

Van Twillert's company is located in a warehouse on the western trading ground in Rotterdam. Van Twillert employs three colleagues, all women. The name of her company refers to the file structure in which the 3D body scans are delivered. A polygon mesh consists of a network of small triangles that together form a certain shape. Mesh is also an air-permeable polyamide, a substance that is very common in lingerie.

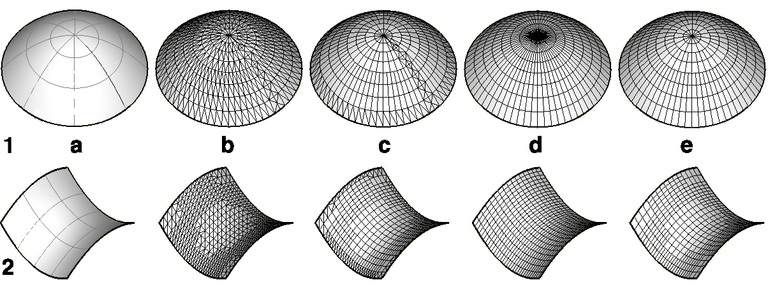

The fashion engineer mainly wants to replace the bra underwire. It often does not connect well to the body. Customers are scanned in the studio with a small, hand-operated 3D scanner. The scanner registers the shapes and converts them into a 3D image, a so-called bodyscan.

I can not say much about the technical details. That belongs to the intellectual property of Mesh Lingerie. They even have developed a method to lift the breast in the desired position. With the help of the bodyscan, they make the fit of the bra, the fabric part and the 3D-printed part that replaces the underwire. The material that comes out of the printer is made of nylon.

The software they use can model everything accurately. This include files for the pattern of the textile part and a 3D file for making the print of the support element. Everything is designed for the unique body. This exact way of measuring is different from that of clothing, using a standard measuring system that does not work properly. Bras from two brands may have the same size, yet their fits will differ. Women have to search endlessly for lingerie that fits them well. At Mesh Lingerie, everything is custom-made: the fit, the distance between the cups, the width of the braces and the depth of the cups. For me, this sounds amazing.

Conservative

Why this approach hasn't been applied much earlier? Van Twillert has a theory about this.

If there were more female engineers, this problem would have been solved years ago. Moreover, the fashion industry is a conservative world, they work according to the principle of trial and error, where a design stays on the market until someone comes up with something better. In other sectors where engineers work, they use calculations and hard figures to get a design right. I prefer this way of working. I work according to an exact approach and do scientific tests to improve a garment.

Her new approach would also be better for the environment. They are working on a circular system. If the textile part is a bit worn, you can come back to the workshop with your bra. Then they make a new bra around the existing 3D-printed structure. Although they first have to test whether that idea works in practice.

Mesh now has a pilot in which thirty women get a bra. She wants to expand that number by attracting women to this innovation through a tour of lingerie shops in different cities. Van Twillert has designed various models. Bras with preformed cups, bras with or without padding and special bustiers where the 3D-printed support is visible on the outside and that you can wear as outerwear. Van Twillert also works on a strapless bra, for example under a gala or wedding dress.

The lingerie is not cheap. Van Twillert and her colleagues manufacture each bra by hand. 'That is rather labor-intensive, because making a bra is a lot more complicated than a T-shirt. Everything must fit together perfectly. One bra costs € 300, including the body scan. But after that first bra, there is no need for a extra scan and the price is reduced to 175 euros.

Van Twillert's dream goes beyond a boutique in the city center of Rotterdam.

I want to change the fashion industry. A bra is a technically challenging product with a clear function: supporting the bust. I see it as my mission to bring the design of the bra to the 21st century, with all the techniques that are available. Soon we will be able to scan 3D with sufficient quality with a smartphone. Then mesh lingerie can conquer the world.

great article, like with many other things, the key point is that there are not enough women both in engineering and in power possitions in most industries, and women's problems are not a priority for the male dominated industries.

If it was a man's traditional task to iron, the autoironing machine would have been invented long time ago.

So, lets celebrate this innovation and encourage more women to take up engineering careers!

Totally agree! To be honest, I do not iron at home. I'm not an engineer, so maybe I can start with that :)