Do you have any money 1$,10$ or maybe even a 100$ bill in your wallet? You most likely have, and do you ever question how it is made? Well ill explain!

You see money is a essential part of life, without it you are nothing and with it you are "something". You see since the roman times money has been very and I mean very used, to trade goods,food and most important technology! So lets see how its made shall we?

...................................

Raw Materials

Money is made out of 75% cotton and 25% linen to give it the "texture" feel. It contains small segments of blue and red fibers scattered throughout for visual identification.

The Manufacturing Process

In the US, all paper is engraved and printed by the Bureau of Engraving and Printing, which is part of the Department of the Treasury of the Federal Government. Every day aprox 36 million pieces of paper (money) is printed (40% is 1$ bills, 25% are 20$ bills) and on average it takes 4 cents to produce.

Engraving The Die

Someone hand cuts the design into a piece of soft steel, known as the "master die", using a very and I mean very fine engraving tool and a magnifying glass. they consist of many dots, lines etc. that are cut into fine pieces of many sizes (if you know what I mean ;D) they are produced by a ruling machine and the scrollwork in the borders are cut using a geometric lathe.

Fun fact: Every time a new Treasurer of the US or a new Secretary of the Treasury is appointed they MUST have their signature engraved on the new "master die"

Making The Printing Plate

When the die has been inspected its heated and pressed into a form to raise the impression of the design. 32 of these raised plastic impressions are bonded together into a so called "alto" Then it is placed into storage.

The magic "alto" is then placed into a plating tank and is plated with copper, the plastic is stripped away leaving the metal also known as the "basso" with 32 recessed impressions of the design. It is cleaned,polished and inspected. If it passes it is plated with chromium to make the surface hard. The front and back side are printed with a a 10,000 sheet stack of paper is filled into a letterpress where they are colored. Keep in mind 16 sheets of paper are made for 1 tiny wee bit of 1$ bill.

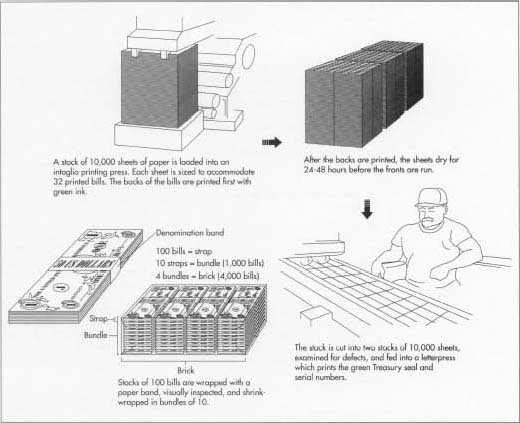

Cutting And Wrapping The Bills

10 sheets are gathered in the stack of 100 and cut into 16 individual stacks of 100 bills each with a vertical knife.All defective bills are replaced with star notes. The 100 bills are then wrapped with a paper band. The banded stacks are given final inspection and are shrink-wrapped with plastic of 10 stacks. 4 of these 10 stack bundles are then wrapped together to form a brick..

Congratulations @tadejloncar! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOP