This is part 3 of the motorized Z-Axis build for my laser cutter

You can find part 1 here

You can find part 2 here

You can find part 3 here

To start off the installation of the bed into the K40 I knew I would have to do some cutting of the K40's base

So I brought the air compressor into my shed

Going to use an Air Nibbler to cut out the area for the stepper motor

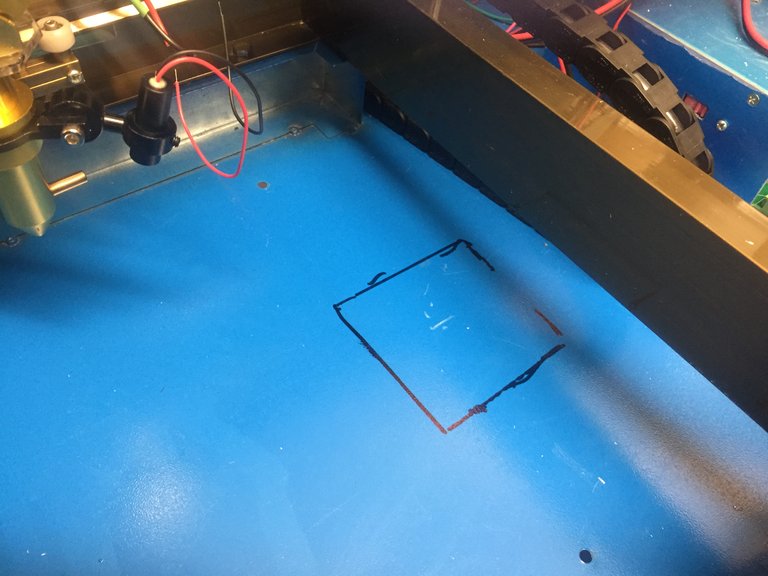

I start by marking with a texta the area that needs to be cut - I made this 60mm x 60mm

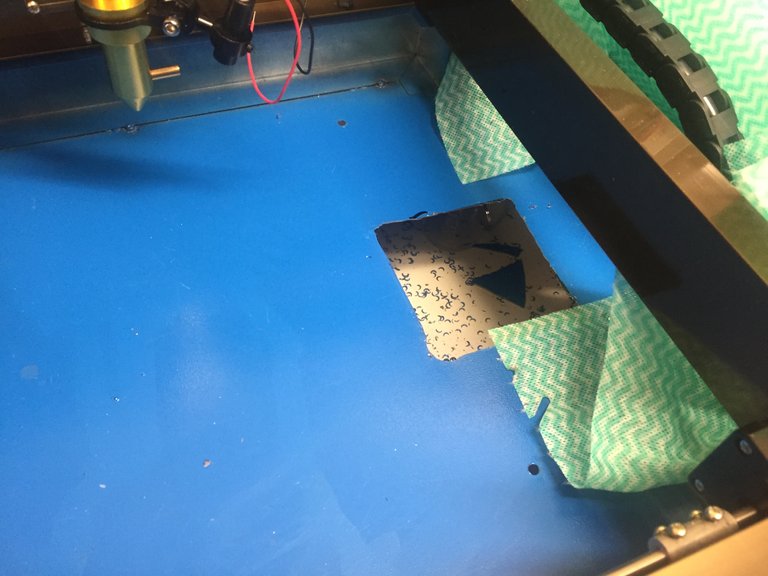

After laying down some cloths over the electronics on the right hand side, so no metal chips go into the electronics, I then drilled a hole large enough for the head of the air nibbler to enter

Once the hole was cut out, I used a clean dry paint brush to sweep the filings out the hole in the bottom onto the desk below (easy clean up)

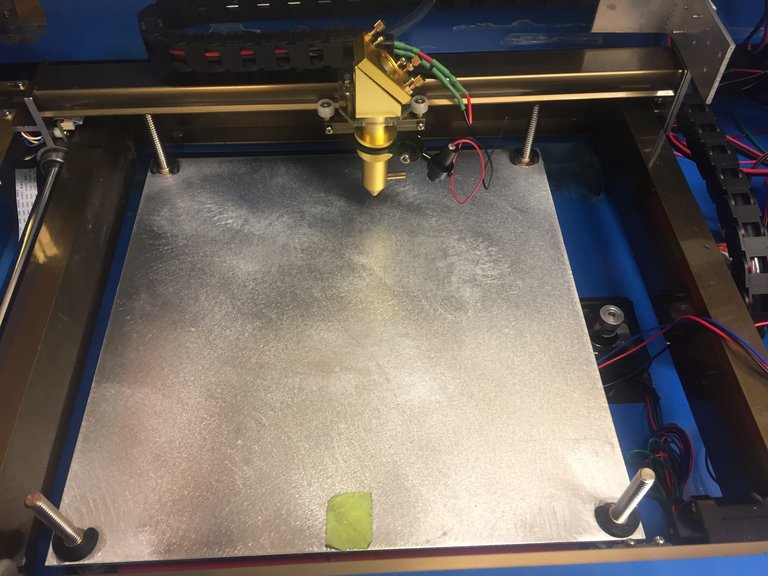

As you can see, it fits perfectly!

Its in!

So with the new laser head, it appears that the table may not go low enough for how I want to use it, so I am toying with the idea of cutting out the whole base where the bed would sit and then using a large sheet of 3mm aluminium to strengthen the structure of the base, once a large part is cut out..

Future modifications! Stay tuned!

congratulations to you @rativie Send 1.000 SBD or 0.800 STEEM to @anonwhale with your post URL in the memo. Get your post resteemed to 10,000+ followers and get a minimum of 40+ upvotes!

@aomura

@drotto

@anonwhale

@getup

@coolbot

@microbot

@minibot

@millibot

Hii im just follow u pls follow me back thanks

https://steemit.com/dmania/@rohanmore/you-must-be-new-here-zg1hbmlh-yere0

Send ur post link in my post im definitely upvote u thanks..

new technology is awsome that is good u info about this i like it keep doing

Support me in my TECH NEWS to grow up it will help and you get the news about new technology

This post has received a 12.52 % upvote from @booster thanks to: @rativiv.