3D printing joins robotics, to allow production in developed countries at lower cost than in countries with cheap labor.

The assembly lines, which from the time of Henry Ford became the traditional method of manufacturing, will have to be strongly impacted as a result of additive technology. Better known as 3D printing, this methodology consists of adding layer on layer from a three-dimensional digital model. In this sense, it is the opposite of subtractive technology, which is how things have been developed up to now. That is, removing layers of a piece of material to obtain the desired shape. As a result of its additive and non-subtractive approach, this form of manufacturing saves many intermediate steps.

Moreover, instead of manufacturing multiple intermediate pieces, to assemble them together, this technology allows printing a final piece directly. As stated by Finbarr Livesey: "One of the first companies to adopt this technology was General Electric ... At present they manufacture a fuel injector directly via 3D technology, which saves them having to manufacture and then weld 18 separate pieces" (From Global to Local, New York, 2017). This directly affects the trade and mobilization of parts and intermediate parts that represent around 60% of international trade.

On the other hand, instead of having to store large inventories of parts and components, the additive technology allows printing on request. This makes inventories obsolete. 3D printing leads, in effect, to manufacturing on demand. Moreover, it allows customized and mass manufacturing of parts and components, based on the customer's specifications. However, this customized mass production can also include end products.

Finbarr Livesey once again presents us with a good example: "We have entered the world of mass production. On the Adidas website you can choose a sports shoe base and then customize it by choosing the color, texture and style, you can even add some text or photo that further customize the customer's specifications ... However, that pair of shoes it will never be manufactured unless the purchase button is clicked on the Web page, which links the manufacture of the product to its specific demand "(cited work).

Thus, Rick Smith and Mitch Free tell us the following: "Manufacturing in 3D printing is the second great wave of manufacturing technology. It is beginning to disrupt a global manufacturing industry of 14 trillion (million) dollars, based on standardized mass production "(The Great Disruption: Competing and Surviving in the Second Wave of the Industrial Revolution, New York, 2016) . This would be the equivalent of moving from collective transport to individual cars.

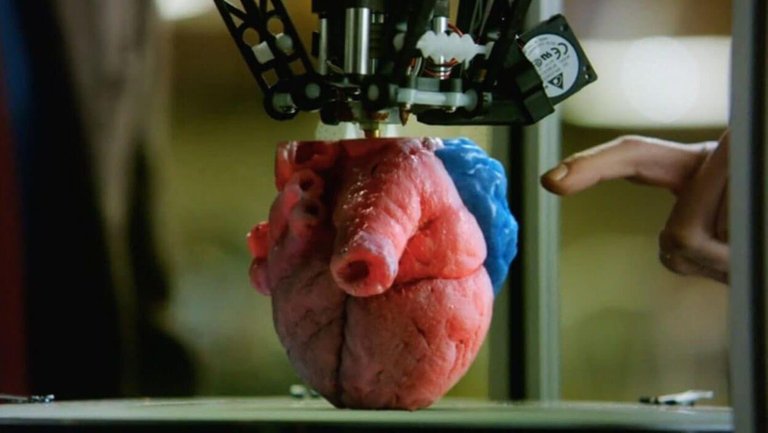

However, in addition to being able to eliminate intermediate manufacturing steps and to be able to customize scale production, 3D printing allows complex designs that escape the assembly line. Again in the words of Rick Smith and Mitch Free: "The additive process, by adding layer after layer, makes it possible to produce extremely complicated objects or simple objects with equal ease. The complexity of the design does not make the manufacturing process more expensive, which allows optimizing the functionality of the piece or product that is desired "(cited work).

Finally, additive technology offers two additional benefits: speed in the production process and lower production volumes close to the consumer market. The first is achieved by avoiding long supply chains, which keep the different parts or components of a final product moving from one end of the world to the other in the middle of successive phases of manufacturing and assembly. The proximity to the consumer market, on its side, allows to adapt the production to the particular size of the market, avoiding overproduction and waste. This, of course, contributes to cheapening the final product.

3D printing is thus linked to robotics, to allow production in developed countries at lower cost than in countries with cheap labor. The case of productive automation is clearer than that of 3D printing. According to Finbarr Livesey, cited above, the total average cost per hour of a robot is five euros, compared to nine euros per hour in the case of a Chinese worker. If robots can work without pause, at a lower cost than their human counterpart in a labor-intensive economy, there is no reason to keep factories on the other side of the world.

Both 3D printing and new robotics are leading to the return of factories to the developed world and with this, considering regressive globalization. The location, synonymous with that return, places the productive processes close to the final consumer. For many labor-intensive emerging economies, it is time to tremble.

Excellent your post you have my vote friend, greetings from venezuela.Votarias my post https://steemit.com/poema/@jjuan1990/como-duele-amarte