Most of cigarettes is made from tobacco leaf. Tabacco plant is initially grow outdoor, in warn regions( tropical countries) the field where the tabacco plant was planted is called seed bed covered with cotoon top sheet, when the plant is almost 10 inch tall they are being transplanted to the field.

tabacco leaves are harvested in one of these two methods the priming and the stalk cutting or manual cutting the leaf.

(Priming)

(Manual)

after the leaf are harvested the next process is called curing(drying) there are three ways to dry the leaf first is the basic air curing, the flue curing which uses a metal pipes that are attached to the furnances .and the fire curing which dries the tabacco with low buring wood fire which tje smoke was directly to the leaf produces aroma and smoky flavor....

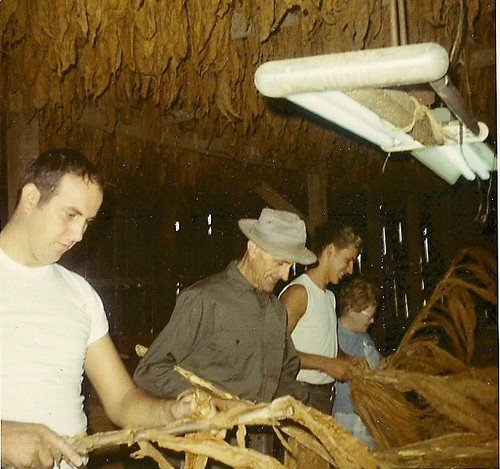

stripping and moistening the tabacco leaf.

tabacco leaves must be moistened into moistening chamber so they will not break if handled...the leaf was sprayed with moisturizer to prevent against cracking /breaking.

sorting and auctioning

tabacco leaves was sorted base on the quality, grades, color and size. after that it will tied in bundles for shipping and finally auctioned to cigarette manufacturers...

the production of making cigarette.

tabacco leaves will pressed and mechaniacally shred...

cigarette ingridients such as menthol or juices will now added to give add.. flvors

shredded tabacco is now dispense over the continuios roll of cig. paper...

the stick of cigarette will cut into desired lenght moderate cig. machines can produes for about 30 cigarettes per seconds,,,..

packing of the cigarettes.

cigararettes wil now pack sealed in .celophane and manually place in carton box...