Hello friends of Steemit!

Many of us are lovers of desserts and infinities of sweets, their raw material is essentially sugar. But will some of us know how this product reaches our homes?

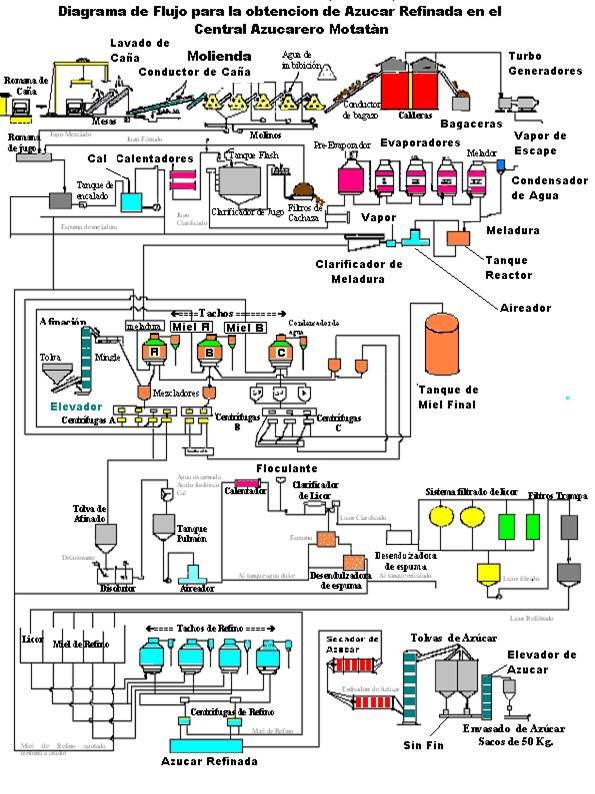

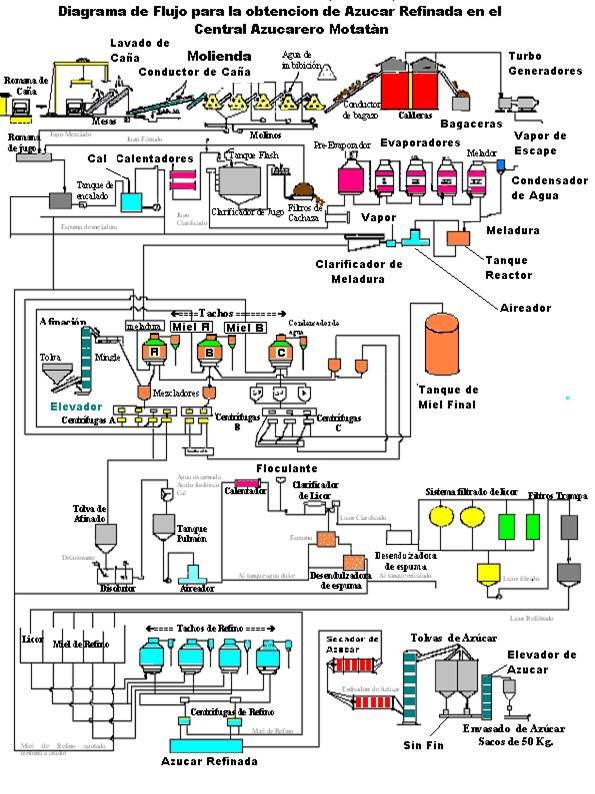

I would like to share with you some images of the route I made some time ago to a sugar mill and to show them how it works, the different processes that transform sugarcane into refined sugar of quality.

The productive process of sugar begins with the arrival in the Central of the cane that is transported in trucks, with weights that oscillate between 10 and 20 tons, this must be weighed before going to the milling in a Roman.

From there, it is directed to the probe, which is a piece of equipment that allows individual sampling that ensures a high percentage of analyzes carried out assuring the equitable payment of the raw material.

At this point the juice is separated with the shredder that goes to the factory for processing and the bagasse that goes to the boiler to be burned and converted into energy.

Stage of Crude: In this stage it begins with the milling or extraction of the juice of the cane. The defibrated cane passes through the tandem of mills.

Alkalization and treatment: The mixed juice from the mills where it is treated with a lime solution (5 ° Baumé) in order to increase the pH from 4.5 to 7.2 and 7.4 approximately.

Clarification: Composed mainly of high molecular weight polyacrylamides that agglomerate the solid particles and decant to the bottom of the clarifier.

Cachaza: This waste is the product of clarification, it is composed of: juice residue, sludge, bagasse and foreign matter separated in the clarification.

Evaporation: Consists of concentrating the clarified juice from 12 ° Brix to 65 ° Brix of approximately density, eliminating much of the water it contains.

Crystallization: This operation is carried out in heat transfer equipment that works under vacuum (26 "Hg), known as tachos, heating with the steam coming from the evaporators.

Centrifugation: Consists in the separation of crystals in cooked masses of mother honey using rotating machines called centrifuges.

Refining Stage: its purpose is to extract the remaining impurities from the refined sugar in order to raise its sucrose content from 98.60% to 99.80% and bring it to the parameters required for the commercialization of refined sugar.

Tuning: It is only applied to imported sugar, in order to prepare it for refining, eliminating the honey content around the glass.

Dissolution: It consists of dissolving the sugar with hot water, applying direct steam in a dissolutor tank until preparing a dissolved between 65 and 70 ° Brix, at a temperature of 80 ° C, this is known as dissolved liquor.

Classification of Liquor: In this process, the impurities contained in the liquor are separated by the phos-flotation method, in which the impurities float.

Filtration: The clarified liquor is passed through three Suchar brand auto filters lined with infusory earth that operate in parallel.

Crystallization: The Central has two buckets for refining adopting a system of four brews. This process consists in depleting the mother liquor through staged brews to lower the purity of the honey.

Centrifugation: It consists in the separation by this physical method of the sugar crystals applying washes according to the cooking that is centrifuging.

Mixing and Drying: This operation is counted with four hoppers to separate the sugars coming from the cooking.

Packaging and Storage: In the container room there is a packing machine of approximately seven bags per minute; the container is 50 Kilograms.

Source: Central Azucarero Motatan.

Source: Central Azucarero Motatan.

The information I show you here was provided by the employees of Central Azucarero Motatán, located in the state of Trujillo, Venezuela.

The images were taken with the BlackBerry 8530.

I hope you have enjoyed knowing a bit about how the sugar industry works and how today we can enjoy a product as good as sugar.

Until an upcoming educational publication!