Creating ear transplants using bacterial cellulose, designing novel architectures for microbial fuel cells or bioremediation of phenol-contaminated water. These are all possible applications of a high degree of control in the structural arrangement of bacteria. This high degree of control has been demonstrated by using 3D-printing to create programmable geometries.

‘Flink’

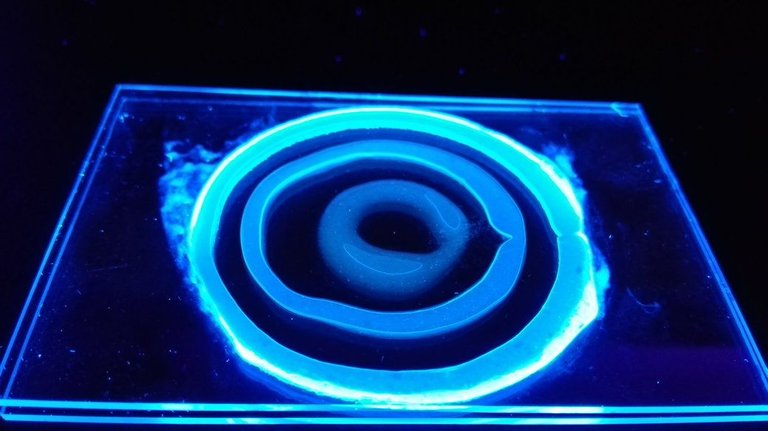

A recently published paper in Science Advances describes the creation of functional living ink, or as the authors call it: 'Flink'. The ink is a 1:1:1 combination of hyaluronic acid, κ-carrageenan, and fumed silica. This causes the ink to have just the right rheological properties to be printed in a 3D-printer. When pressure is applied to the ink it flows out of the printer. Afterwards, when it has deposited, the material properties transfer from a liquid-like to solid-like so that the shape of the printed materials stays intact. In more scientific terms this means that the destabilizing gravitational and capillary forces are insufficient to overcome the yield stress and storage modulus of the material. Combined with the quick elastic recovery the result is that the material keeps its printed shape, at least if the total solid concentration is high enough (Fig. 1).

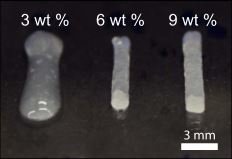

Fig 1. The effect of concentration on the rheological stability after printing (wt% means weight percentage).1

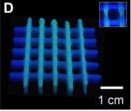

Now that an ink has been made with the rheological properties required for printing the bacteria can be added into the mix. Here is where the options start to open up. Bacteria have endless utility, therefore the decision on which bacteria to add the ink depends on the desired utility. As an example, the authors have labeled a bacterial strain called P. putida with a blue marker and another strain called B. subtilis with a green marker. Below you see a picture of a matrix created with the printer (Fig. 2). Can you guess which lines are which strain?

Fig 2. A printed matrix of P. putida and B. subtilis. 1

Cellulose scaffolding

One exciting application of this technique is the creation of scaffolding for producing structures out of bacterial cellulose. The bacteria Acetobacter xylinum is able to produce surprisingly strong hydrogels by secretion of nanocellulose. In the medical industry, they primarily use this feature to produce artificial skin, although there are many other possibilities. Right now the bacterial cellulose has already been used to make ear transplants, implants with specific surface patterns, and to mimic blood vessels. In the picture below you see how the 3D printing technique is used with Flink to create skin transplants.

Fig 3. Examples of the application of 3D printing living matter. Left: A 3D-printed cellulose structure, produced by A. xylinum, in the shape of a T-shirt. Right: A doll face was scanned, subsequently A. xylinum in Flink was deposited onto the face to create a cellulose-reinforced hydrogel. This hydrogel can serve as skin transplant once biological residue has been removed. 1

To me, 3D-printing is becoming a very interesting technique. It is highly applicable in many fields because it is so versatile. It has now allowed us to print 'living matter'!

Here are some plush microbes to end this post!

References:

3D printing of bacteria into functional complex materials

The Lost Atmosphere

A Killer in Space

Errors of experimentation

Total Daily Energy Expenditure

2017 – Obesity updateRecently from @Altherion

I am more and more amazed by the technological improvements done in the past 5 years. Technology grows more and more each year.

I know! The rate at which these technologies starts popping up seems to be increasing. Perhaps Ray Kurzweil was right about accelerating returns.

Congratulations @altherion! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOP