"A Quick Overview of Ceramic Glaze to Ceramic Products"

There are two types of ceramic products; glaze and unglazed and almost all ceramic products today are covered with glazes. Either for decorative purposes, to hide surface defects and imperfections, primary protection against abrasion or to add strength and hardness, glaze has been most commonly used in ceramic industries. In fact, glazing of ceramic product has long been present even during the ancient times. The first recorded history for glaze use was dated way back 13th century B.C. in the Elamite Temple at Chogha Zanbel.

According to Wikipedia, ceramic glaze is an impervious layer or coating of a vitreous substance which has been fused to a ceramic body through high temperature firing. The general purpose of glaze before was only for decoration until modern ceramist and engineers have developed advance glaze formulation primarily designed to add strength to ceramic materials. There are also ceramic glazes applied on wall tiles to obtain self-cleaning properties.

Today, glaze has also been use for more than one purpose only. Glazes are applied to ceramic products to enhance properties and to become more effective accordingly based on its designated functionality. For example glazing earthenware products eradicates porosity, thus allowing the product to hold liquid for distinctive use such as for cups and as kitchen wares. Moreover, coefficient of friction of glazed products decreases due to glaze vitrification making the product easy to clean.

Furthermore, aside from glaze colors, glazes can also be on formed on various surface designs such as being glossy and matte. For instance floor tiles are most of the time glossy but could sometimes be matte depending on their functionality and on where they are intended to be used. Bathroom floor tiles are usually designed matte to add abrasion and avoid accidents. Wall tiles on the other hand are mostly glossy. There are even wall tiles designed through nanotechnology to become self-cleaning tiles.

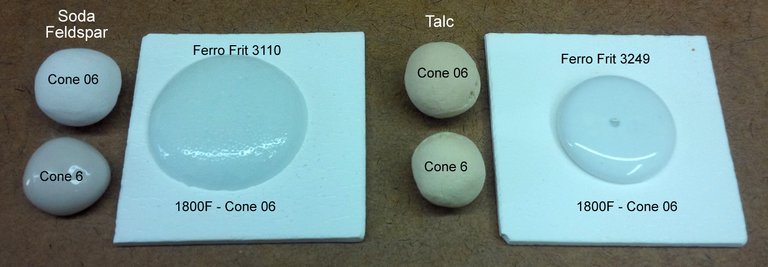

Glazes are primarily made of ceramic flux or the melting agent which partially melts first during firing. Thus flux vitrifies at lower temperature compared to other components and therefore its addition to glaze formulation lowers the high melting point of silica which is the glass former component of glaze. Clay in such cases can be used as primary source of silica if elemental analysis is given. Clay can also be source of other components such as alumina.

And so, the raw materials and primary components used for making ceramic glazes are mainly silica, alumina, colorants, opacifiers and metal oxides or fluxing agents. Silica acts as the glass former during firing of these components while alumina on the other hand prevents the liquefied fired glaze from running off the ceramic product. Various metal oxides such as calcium and potassium acts as fluxing agents with lowers the melting temperature of silica and the other components are self-explanatory.

The combination of these components, the glass former, fluxing agent and run-off agent determines the melting temperature of the glaze which is called the maturity temperature. There are important groups of traditional glazes today which are named after their main fluxing agent component. And according to Wikipedia, these are;

1.) Lead-glazed earthenware which is shiny and transparent after firing, which only needs about 800 °C (1,470 °F). Used for about 2,000 years around the Mediterranean, in Europe and China.

Lead glazing in ceramic industry has been discouraged due to its potential harmful effects. Lead glazing in ceramic industry has been heavily monitored by government due to its high toxicity and its bioaccumulation ability.

2.) Tin-glazed pottery, which coats the ware with an opaque white glaze. Known in the Ancient Near East and then important in Islamic pottery, from which it passed to Europe.

Tin glazing on the other hand was made unpopular with the introduction of enamel glazing during the 18th century. The advancement has gained much favor due to its proficiency to be fired at much lower temperature.

3.) Salt-glazed ware, mostly European stoneware which uses ordinary salt.

4.) Ash glaze, important in East Asia, simply made from wood or plant ash, which contains potash and lime.

5.) Feldspathic glazes of porcelain.

Today, modern glazing has advanced far enough to be able to produce different glazing combinations, appearances and properties of ceramic products. There have also been modern methods of application which are being practiced by most ceramic industries today. Machines for automatic application of glaze have also been created and modernized. So whatever is the target for glaze application, the most important information is the basic of glaze components.

THANK YOU FOR TAKING THE TIME TO READ MY POST

Electric Mosquito Net with Silica Fabric (Ceramic) Insulator

Don't Miss This Year's Orionid Meteor Shower!

The Natural Occurrence of Clayey Raw Minerals

Diamonds Are Not Forever if We Understand its Nature and its Crystal Structure

References:

https://en.wikipedia.org/wiki/Ceramic_glaze

https://en.wikipedia.org/wiki/Glaze

https://ourpastimes.com/the-history-of-glazing-12311173.html

https://www.pcc.edu/staff/pdf/957/IntroductiontoGlazeComposition.pdf

https://www.ceramicindustry.com/articles/86816-glaze-basics

http://www.americantileandstone.com/contentpage.aspx?Id=19765

Thanks for the post. Interesting read.

I wanted to make a crucible to melt aluminium.

I thought about using glaze as a heat protector, would that work?

It's okay if you do not coat you ceramic product with glaze, aluminum melts below 700 degrees Celsius, you can use stoneware body for your crucible. You can save time and money :)

nice and very informative post :)

Good information!

@mrainp420 has voted on behalf of @minnowpond. If you would like to recieve upvotes from minnowponds team on all your posts, simply FOLLOW @minnowpond.

To receive an upvote send 0.25 SBD to @minnowpond with your posts url as the memo To receive an reSteem send 0.75 SBD to @minnowpond with your posts url as the memo To receive an upvote and a reSteem send 1.00SBD to @minnowpond with your posts url as the memohey there my friend! ^_- how are you?

this is an interesting content. Makes me want to buy some ceramic teacups as a souvenir. I think I would go for MT9. It looks pretty, don't you think?

Hello Gillaine, I'm fine.. Those are just sample names made by the people who conducted the experiment :)

Good work very informative post.

Great post thank u for sharing love it

parang donut lang pala to @asbonclz ? na may glaze ? galing galing

on a serious note, does glazing affects the thermal property of ceramics? Meaning does it dissipates less heat? I noticed, when using a glazed ceramic cup for my coffee, the warm temperature (of coffee) is preserved longer than using an unglazed cup.

Haha parang ganon na nga pero mahirap yan @precise kasi yung ibang glaze nag run-off, dapat compatiple sila sa ceramic body, dapat ang expansion nila almost the same lang. Maraming problema ang glaze lalo na mali formulation.

Most glaze bai NO, lalo na sa mga cups, NO. Pero naay mga ceramic coatings bai nga low ug thermal conductivity. Naa gale coatings bai na maka withstand ug very high temperature, naa to sila'y mga secret components hahaha mga lightweight hollow ceramic materials, one example is diatomite.