A few months ago, I was opportune to spend some time at Uyi Technical company (UTC) in the southern part of Nigeria. I had studied Mechanical Engineering for about three years but I hadn't acquired any field experience or a real world opportunity to put all I had been taught into practice. So when this chance came I gladly took it with open arms. I will be sharing a little of the knowledge I gained while working at A Technical integrated facility.

I was posted to different facilities at different times but I will talk more on the Engine Block.

Engine Block

Engine Blocks known as Cylinder block are the vast casings that contain the Cylinder and its internal components, intake and exhaust passages, coolant passages, crankcases, and other internal components. As some machine become more advanced and efficient, the classic Engine Block is becoming less and less recognizable. Some components of engines or systems are so highly integrated that the need for a bulky “casing” for internal parts is rare. Advancement of engineering technology also makes automotive manufacturing less reliant on casings and what some may call “non-functioning” parts.

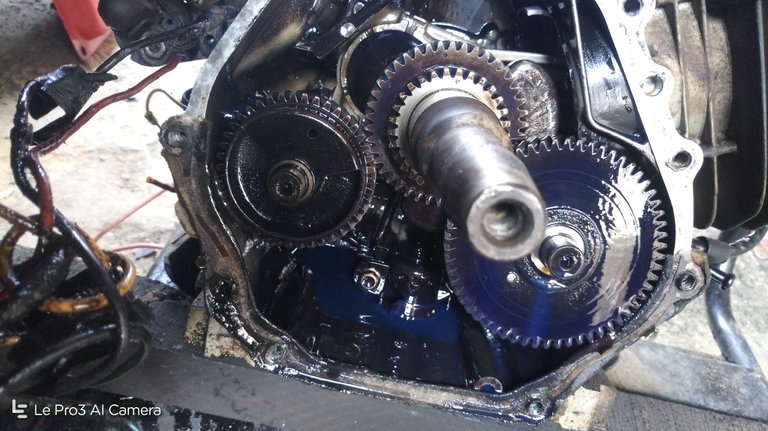

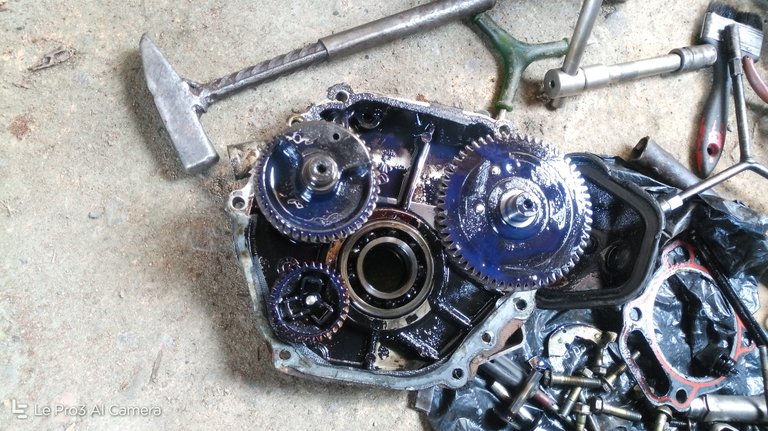

How to Fix The Block Engine

Step 1 – making ready the block the engine will very likely have to be removed, so be ready to do this. It is not an easy job and it takes quite a serious amount of dismantling of parts and components to get the block out.

Step 2 – Assessing the Crack : know how deep or long the crack is in your engine will determine a better way to fix it. It will also determine whether it can be fixed. Cast iron is not simple to weld and it takes a very skilled person to mend a cast iron engine block with welding equipment. If the crack is less than 8 inches long and less than 1/8 of an inch wide it is very probably that you can fix it with a metal stitching kit and epoxy.

Step 3 – Cleaning the Wound: The crack needs to be completely clean before you proceed any further.You could Use the wire brush to clean the crack and make sure there is no residue grit, grime or dirt in and around the crack. If the crack is too wide to use the brush then just wipe it clean with a damp cloth and use a tag rag. Even the most minute pieces of grit or dust can cause issues with the cylinders, so do not let any get inside the crack.

Step 4 – Stitching the Wound: handle a "stitch" from the kit box and insert it into the crack with the hammer. Depending on the type of kit you buy, your stitch may or may not have"shoulders". The shoulders help you to hammer the stitch deeper into the crack for better adhesion and a cleaner finish. Other stitches might be equipped with break-off grooves that cab be taken off at a predefined place, once inside the crack with the torque wrench.IMG_20180607_083806.jpg

Step 5 – Epoxy: Use an epoxy compound suitable for engine block fix. With the stitches in place apply the epoxy into the crack as far as you can put it andthen fill the crack completely. Cover over the surface and smooth the epoxy for a neater join.

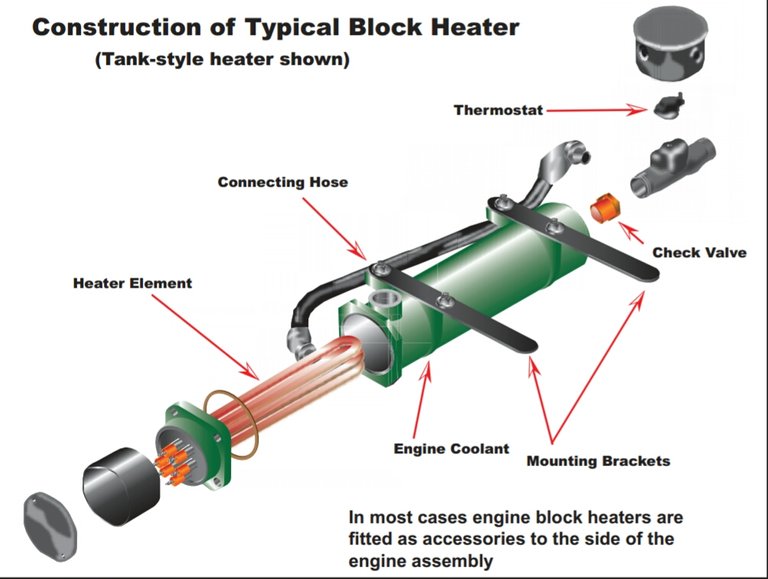

What is Engine Block Heater

A block heater warms an engine to Enhanced the chances that the engine will start as well as warm up the machine faster than it normally would in extremely cold weather.

When engine block heaters used

Engine block heaters are mainly supplied and installed as an accessory and form part of the original, standard equipment from all

standby generator set manufacturers. They are used where the generator is subject to ambient temperature below 60°F (16°C) in

order to preheat the water jacket coolant of the diesel/natural gas ‘driver’ engine and maintain it, thus assisting the engine start cycle

for rapid, easy ‘on-line’ performance.

Different types of block heaters

There are a number of different kinds of block heaters to operate while the engine-driven generator is shutdown in

colder climates, which we describe below:

1.Radiator-hose heater - This heater is fitted into the bottom radiator hose and the coolant circulates by thermal

convection.

The heater range is limited by available hose sizes and due to relatively low watts (typically 400 to 600 watts). This

normally makes radiator hose heaters unsuitable for preheating large engines and we would rarely recommend

this type for most standby generators above 15kW.

2.Freeze plug heater - They are fitted in the engine block using a freeze plug hole in the cylinder/

crankcase and protrude into the coolant chamber. They serve to circulate heated coolant throughout the block

by thermal siphon action. The downside of this type is risk of coolant leaks.

3.Tank-style heaters - They are installed on or close to the engine and connected to the coolant circuit, and

powered by single or three phase AC source via a power cord, while the engine is stationary. They are available in

sizes from 500 to 5000 watts, dependent on the engine displacement and the ambient temperature encountered

at site. They circulate the coolant throughout the engine and can be adjusted by a thermostat, if needed, to

ensure the coolant is kept at the correct temperature or even have an automatic clock-controlled timer. The

heater is automatically shut off once start cycle is initiated by means of an oil pressure sensor switch. On larger

engines, the tank-style heater can be supplied with a circulating pump, rather than relying on convection.

Benefits of using engine block heaters

The key reason for using an engine block heater is to maintain the engine at a temperature above 60o F (16o C) to ensure

it starts quickly when required. Cold engines can take a considerable time to crank up during which time the starter

batteries will be heavily discharged. However apart from a starting aid, the heaters provide the following additional

benefits:

1.Reduces engine wear - Engine wear could be reduced by up to 50%. The lubricating oil is also kept warm and thus

ensures that the essential oil is immediately pumped to the critical moving parts and points of the engine during

the start cycle.

2.Saves fuel - It is not necessary to leave engines idling to maintain them above the required starting temperature.

Reduced exhaust emissions on start - Engines are designed to emit lower emissions at their operational

temperature.

3.Less stress on other components - Batteries when cold have a reduced ampere hour capacity and starting a cold

engine can put a considerable drain on a battery system.

4.Engine sump - An engine system left for a length of time in cold

temperatures will see an increase in water build up due to condensation. Keeping the engine warmer than the

surrounding ambient significantly reduces condensation.

Maintenance points for engine block heaters

As with all major components, regular maintenance will ensure the equipment remains in full operation and ready to

perform its function when required. The following are key maintenance points for engine block heaters:

1.Clips - Always be check these items when carrying out routine maintenance (preferably weekly in extreme

conditions) on the generator to ensure that it is functioning correctly and the element is not damaged.

2.Hoses - Any hoses found not to be pliable should be changed every three years.

3.Coolant mix - It is important that the correct mix of coolant is used to avoid damage to the block heater.

Common problems with engine blocks

Being a big, precision machined, hunk of metal, the engine block is designed to last the lifetime of the Machine. But sometimes things do go wrong. These are the most common engine block failures:

1.External engine coolant leak

Puddle of water/antifreeze under the engine? It might be caused by a leak from the water pump, radiator, heater core, or a loose hose, but sometimes it’s the engine block itself. The block can crack and begin leaking, or a freeze out plug could work its way loose or rust out. Freeze out plugs can be easily replaced, but cracks are usually terminal.

2.Worn/cracked cylinder

Eventually, after hundreds of thousands of miles, the smooth machined walls of the cylinders will wear to a point where the piston rings can't seal against them well. On rare occasion, the cylinder wall can develop a crack, which will quickly result in a motor needing a rebuild. Worn cylinders can be bored larger, for oversized pistons, and in extreme cases (or in aluminum blocks) iron sleeves can be inserted to make the cylinder walls perfect once again.

3.Porous engine block

Caused by contaminants which got into the metal during the manufacturing process, voids in the casting often cause no issues at all for a long time. Eventually a poorly cast block can start to seep and leak, either oil or coolant, from the area where the imperfections are. There's nothing you can do about a porous engine block, because it'll have been faulty from the day it was molded. Having said that, any leaks that may arise from a porous block should be minor and if they surface within the manufacturer's warranty period the engine should be replaced free of charge.

Congratulations @graywood! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!