Introduction

The word meat derives from the Latin CARNIS; that in Greek is called Kreas and from this voice the names derive to two of its characteristic components: creatine and creatinine.Textual quotation: Book of MEAT AND MEAT PRODUCTS. Prof. Dr. Hennann Schmidt Hebbel. 1984. Chile.

It is worth mentioning that meat is an essential food for sustenance in human nutrition, that is why it is of the utmost importance that we learn from its different forms of processing and conservation, for which I present in the following article all the biochemical aspects and the different technologies applied for the processing and generation of meat products.

The muscle tissue of mammalian flesh is made up of giant cells, called fibers that measure from 1mm to several cm long, which are held together and wrapped by a membrane of connective tissue, called sarcolemma or estrone. Inside the fibers and bathing in the liquid or sarcoplasm that fills them are numerous myofibrils of only 1 micrometer (thousandth of a mm) in diameter and which constitutes the contractile system of the muscles. Textual quotation: Book of MEAT AND MEAT PRODUCTS. Prof. Dr. Hennann Schmidt Hebbel. 1984. Chile.

This structural form of the meat supposes great challenges for the processing of the same, its study and comprehension will facilitate all the studies that can be made to diagnose all the applicable ways to generate the best operational practices in the slaughterhouses, these practices must be based on choose the best cuts based on the structural shape of the meat, its muscular support system will be part of the guide to separate and depulp the animal chosen for slaughter.

Components responsible for the aroma and taste of meat

It is from the biological study and chemical reactions that we can study all the elements that influence the taste and aroma of the meat.

Raw meat has only a weak aroma, which develops along with tenderness during the maturation phase, 2 to 3 hours post-mortem in cattle.

Interesting are the transformations that meat undergoes through cooking and roasting. The entire molecular and chemical structure of the meat is altered after it is subjected to a certain pressure and temperature (cooking or roasting the meat). It is necessary that we analyze separately the chemical reactions that occur within the molecular composition of the meat, studying its two ways of being subjected to temperature:

- Cooking: with water, it determines a weight loss of 20 to 40%, since the cell juice, melted fat and extractive substances pass into the broth, which is due to its stimulating action on the appetite. Collagen, in part, dissolves to the state of gelatin, and proteins, such as myoglobin, coagulate and transform; the flesh becomes gray and more digestible. On the other hand, if the meat is introduced in boiling water, the protids on the surface coagulate and the crust prevents the diffusion of the juice and its soluble components, resulting in a meat with a more pleasant flavor, but a tasteless broth.

-** Roast**: determines a weight loss of 20 to 25% and the formation of a crust of coagulated proteins and melted fat that prevents the extraction of extractive substances. In addition, certain aromatic substances are formed from fats and proteins in the juice.

Without comparing the two forms of temperature subjection of meat we can realize that there is a considerable weight loss due to cooking compared to roast, the easiest ways to analyze its flavor is by studying the chemical reactions that occur in the two modes: Cooking and roasting.

According to the way in which the meat is cooked and roasted, it has been possible to identify a large number of chemical substances, both fixed and volatile, which together determine the aroma and flavor of the meat subjected to heat; acting as precursors, the complex reactions generated by compounds such as peptides, thiamine, hydrogen sulfide and ammonia, among many others. Only some of the resulting substances present by themselves an aromatic note related to the meat extract; they are generally sulfur compounds such as methional, 2-formyl thiophene, 5-methylfurfural and 3,5-dimethyl-l, 2,4-tritonal (or tetrahydrothiophene).

What we can conclude with these two forms of cooking is that its study and analysis will provide us with the necessary knowledge to be able to add flavor to the different forms that we can apply to the different processes of maturation, conservation and processing of meats in sausages and other forms more of processing.

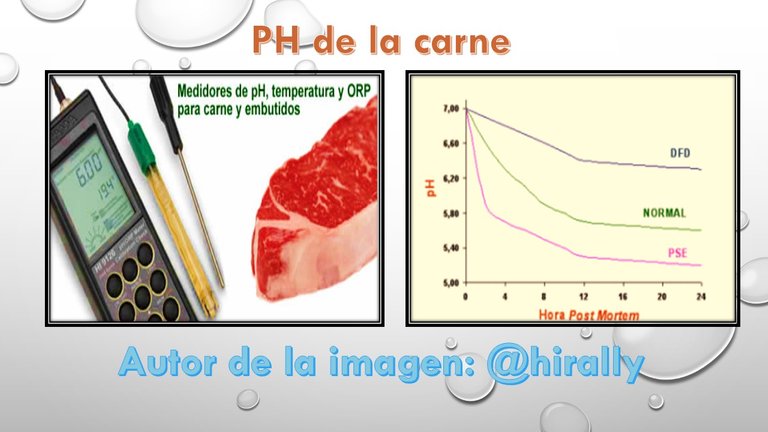

Influence of PH on meats

The slaughtering process generates, together with structural modifications in the meat, a series of biochemical transformations that manifest themselves, among other phenomena, by a deviation of the carbohydrate metabolism towards glycolysis with the formation of lactic acid that remains in the muscle and a decrease in the energy-active compounds such as ATP and ADP and phosphocreatine, which triggers the cadaveric rigidity (rigor mortis).

As a consequence there is a post-mortem decrease (p.m.) in the pH of the meat that reaches, in the first 24 hours, from 6.5 to 7.5 in the living muscle to values of 5.4 to 5.8; what depends on the initial glycogen reserve.

Both the magnitude and speed of this decrease in pH significantly influence the water retention power of muscle tissue, and fluid exudation can occur. But at the same time it limits the activity of putrefaction bacteria, acting as a selective barrier of the contaminating flora and also favors the activity of the proteolytic enzymes of the meat (cathepsins), whose autolytic transformations later determine the maturation of the meat. With this maturation process, the meat acquires its softest, juiciest and nicest-tasting texture, at the same time favoring its preservation capacity.

The behavior of myofibrillar proteins in terms of their water retention capacity is very dependent on the pH factor. Thus, at a neutral pH (6,8-7), its retention capacity is maximum, due to the disposition of the negative electrical charges of the protein molecules.

From the technological point of view, the Meat can come to present a bad retention of water, because the violent descent of the pH to less than 5,8 causes a partial protein denaturation; but it shows a good penetration of the salt in the dry curing. It can be used in raw sausages, by mixing up to 30% with normal beef or pork.

In the elaboration of raw meat products the most appropriate pH zone is between 5.5 and 5.8 in which the meat has a covered structure, that is, the muscle fibers are widely separated from each other and thus, the salt, Curing substances and other additives can penetrate more easily into the interior of the pieces of meat.

Therefore, pH measurement is fundamental, both to recognize the 2 extreme types of meat that have been described, as well as to select them properly and detect the degree of acidification in the maturation of meat products.

Conclusion

The engineering applied to the processing and conservation of beef, beef, poultry, among others, requires the strict importance of the study of biochemical reactions, these reactions go through several and diverse processes, since the animal is brought to its slaughtering process where it produces a high stress, making this change its chemical composition, to go through the different levels and types of cooking, the level of the pH is fundamental for its curing process, in it the amounts of salt adhere in a better way, making the meat is preserved in the best way, and maintains its aroma and flavor to the palate of those who consume it.

In food engineering, the study of meat products is fundamental, for them a series of technologies have been developed in the process of generating sausages from beef, pork and poultry. Once the meat is subjected to some conservation process, it is easier for its consumers to access it, since it may last longer for its subsequent consumption. In food engineering, we do not limit ourselves only to the study of the preservation of meat, but also to generate the different processes that help it to maintain good taste and aroma in its consumption, that is where apart from its conservation all technical and experimental efforts must be directed.

Bibliography consulted

Book of MEAT AND MEAT PRODUCTS. Prof. Dr. Hennann Schmidt Hebbel. 1984. Chile.

Meat is cool. It makes your muscles grow! <333

Congratulations @hirally! You have completed the following achievement on Steemit and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOPCongratulations @hirally! You have completed the following achievement on the Steem blockchain and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOPDo not miss the last post from @steemitboard:

Congratulations @hirally! You have completed the following achievement on the Steem blockchain and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOPDo not miss the last post from @steemitboard: