Poultry egg incubation is an activity that requires sustainable energy supply for efficient performance, operation and profitability. This involves the management of fertilized poultry eggs to a satisfactory development level that leads to normal chicks. It includes the control of the extrinsic environmental factors of the surrounding.

Naturally, a mother hen performs this function but at low efficiency. And artificially, an incubator, a special system that simulates the environmental conditions required for such operation is usually employed by poultry farmers to do the same operation within specified temperature and relative humidity range. The ranges are usually between temperature and relative humidity of between 36 – 39oc and 50 – 70% respectively. To maintain this temperature, range sustained heat supply is paramount. In the most developing countries, the vast majority of poultry farmers in the rural communities operate their farms on small scale and/or even subsistence level. They often use a collection of bush lamps and kerosene stoves to achieve the heating requirements of the small hatcheries and brooders for day-old chicks.

The problems with these systems are enormous ranging from environmental pollution and fire outbreak. Use of fossil fuel is known to produce toxic gases which are harmful to eggs and poultry attendants. Electricity based egg incubators are known to produce clean energy without harmful effects on the environs but they are however limited in operation due to the initial cost of procuring such equipment coupled with the high cost of electric bill, frequent power outages where grid electric exists and the unavailability especially in the rural areas.

For sustainability in poultry chick production, the need for sustainable and environmentally friendly energy supply resource can never be over-estimated. Such energy resource measure should be attractive and easy to come by or renewed by nature for example the use of solar energy. A special feature of solar powered incubator is that it could harness solar energy by using available materials. and is adaptable to both rural and urban poultry productions. Major advantage of solar powered poultry egg incubator is that it could lead to a pollution-free environment, systems that are free from fire hazards and the development of small, medium to large-scale commercial incubators.

Survey has revealed that at the present there is no commercially functioning poultry egg incubator in the southeastern part of Nigeria. The day old chicks’ supplied to the zone come either from the southwest or northern parts of Nigeria. The poultry farmers in the zone has no option order than to purchase the day chicks at very exorbitant rates at about three hundred naira (N300) about two US dollars ($2) per chick due to high cost of logistics and transportation.

Few individuals that own low capacity incubators ranging from 100 – 300 eggs which are powered by fossil fuel kerosene systems, generators or the combination in the process. They often collect and hatch eggs for individuals at non-refundable charge of about one dollar ($1) per egg. To an average Nigerian poultry farmer this amount is considered very costly. The direct effect is high cost of day old chicks. Majority of the incubators operate at very low capacity at about 20% efficient. (Okonkwo et al 2012)

*Solar Energy/Photovoltaic

In Nigeria, rapidly escalating costs of petroleum based products have forced farmers, government officials and scientists to re-evaluate present farming practices and to search for alternatives of petroleum based agriculture. Solar energy has for ages been used in crop drying while cooking with solar energy is more recent practice (Yohanna, 2004). Generally, sun drying applies to spreading the crop in the sun on a suitable surface such as roadsides, mats, hanging crops from the eaves on building, trees etc and drying on the stalk by standing in stock or buddle as practiced in many parts of Northern Nigeria.

The essential parts of any solar thermal power generating scheme are a means of collecting solar energy; provision of suitable thermal converter and mechanical converter and a method of strong energy for use in non-solar or low solar periods (Stine and Harrigan, 1985). Solar energy plays a vital role in agriculture.

*Solar energy utilization in Nigerian Agriculture

It provides energy without noise because it has no movement in their parts. It provides energy without wastes and do not need waste material for energy production nor produce waste during the course of producing energy.

Solar photovoltaic (PV) technology supplies electricity without combustion. It has less maintenance since nothing is consumed or weared during their operation.

Direct solar energy conversion devices are generally either solar thermal or solar electric while solar thermal system can be extended to produce electricity, both systems can be developed to produce mechanical power. Thus, solar radiation can be applied in agricultural processing which requires heating or cooling such as drying, refrigeration and lighting, water pumping, grinding, threshing and other size reduction processes as well as in conveyance and transportation

*Utilization of Solar Energy in egg incubation

Design provision must be made for humidifying the air. For forced air circulation hatcheries, a wick type cloth dropping into a pod of water may be used to increase moisture evaporation into the hatching space. The components consist of a solar air heater, glazed with a single thin PVC corrugated sheet. The exit of the heater is directed to the egg chamber containing a natural circulation tubular exchanger, egg trays, water trough and humidifying cloth wick.

For heating at night a rock filled drum painted black in the outside is provided as a heat storage medium. The full ducting allows for the warm air to flow through the drum on sunny days before entering the egg chamber. The black painted drum surface also acts as a solar collector plate. The heat stored in the rocks is then utilized in the night. On overcast days, the air flows directly into the chamber (Okonkwo and Akubuo, 2001; Singh 1990) (Yohanna et al 2010)

*Incubation and Embryonic Development

Embryonic development is a continuous process that can roughly be divided into three different phases. They are differentiation, growth and the maturation. Typically, differentiation of organs occurs in the first days of incubation. The growth and the maturation of the organs occur in the later phases of development. Each of these phases requires specific incubator conditions. As the embryo grows, its metabolic rate increases and this is accompanied by increased heat production.

Consequently, the natural pattern of the embryo and eggshell temperature shows an increase towards the end of incubation. In the incubator we must differentiate between the temperature set point at which the incubator operates and the temperature of the air at the level of the eggs, which determines the temperature of the egg and embryo. At the start of incubation, the embryo produces little heat and eggs must be warmed. This means that the air temperature must be higher than the egg temperature. As the embryo grows, metabolic heat production increases and to prevent overheating the air surrounding, the eggs must be cooled such that heat is removed from the eggs.

Incubators are machines, which artificially provide the egg with the correct, controlled environment for the developing chick. Incubators are mainly classified into two based on the source used for heat generation method. They are electrical incubators, nonelectrical egg incubators and solar thermal hybrid incubators.

Novice poultry producers usually become interested in artificial incubation of their own chicks. The success of this type project depends on proper care and incubation of the hatching eggs so healthy, vigorous chicks are produced. Many times a producer carefully attends to the incubation process but disregards the care of the eggs before they are placed in the incubator. Even before incubation starts the embryo is developing and needs proper care. Hatching eggs suffer from reduced hatchability if the eggs are not cared for properly.

The size and type of incubator selected depends on the needs and future plans of each producer. Many different models are available. For continuous settings, separate incubator and hatcher units are recommended. If all eggs in the unit are at the same stage of incubation, a single unit can be used. Locate the incubator and hatcher units indoors to protect them from major weather changes. It is essential that the room has a good ventilation system to supply plenty of fresh air. Keeping the units indoors makes it easier to maintain uniform temperature and humidity.

*Types of Incubator

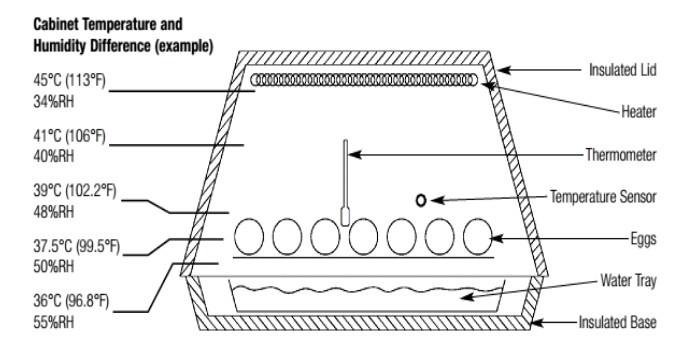

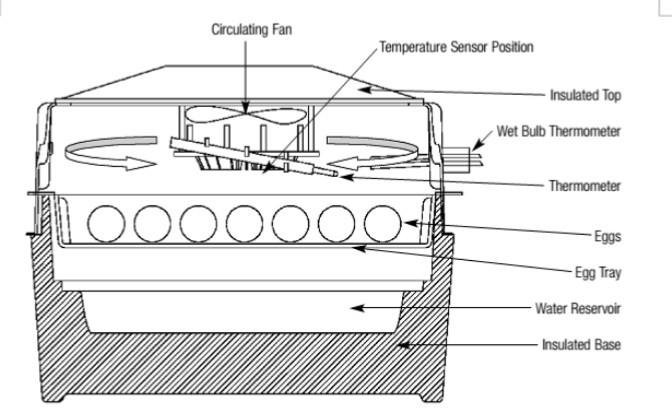

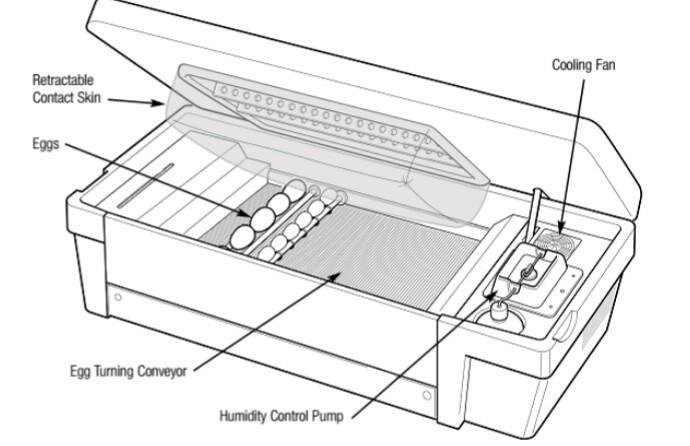

Vinusankar et al (2015) has it that electrical incubators can be classed as Still Air, Forced Draft and Contact types according to how air is circulated. Still air incubators are the most basic form of incubator. A still air incubator is basically an insulated box consisting of a heating element, temperature controller, egg tray and water tray. Due to still air inside the chamber a temperature gradient is formed. In a forced draft incubator, a fan is used to circulate the air inside the box, thereby temperature gradient can be avoided. Contact incubators are a new generation of machines designed to mimic natural incubation much more closely. The lid with the attached skin mimics the functions of an incubating parent. In non-electrical incubators the sources used for heat generation for maintaining the incubator temperature difference was different. (vinusankar et al, 2015)

Incubators of several types and capacities with adapters for eggs from different species are available. Basically, an incubator is a box that holds and rotates eggs while maintaining appropriate temperature, humidity and oxygen levels.

An automatic rotator rotates eggs at least twice a day. Humidifiers are of several types; some are actuated by wet bulb systems while others are designed to maintain humidity by a simple water reservoir surface area system. Either of these systems can be used effectively. Temperature can be controlled by the older wafer system or by newer microprocessor systems. Whatever the system chosen, an incubator with a backup controller set at less than 102°F (38.9°C) can save the hatch if the primary temperature controller ever malfunctions. Remembering that temperature, humidity, ventilation and turning are the important factor during incubation, so these factors are to be monitored.

*Still Air Incubators

Still air incubators are the most basic form of incubator. A still air incubator is basically an insulated box consisting of a Heating element, a Thermostat or temperature controller to control temperature, Egg tray, a thermometer to measure the air temperature, a tray for water. Some machines however may have a hygrometer for humidity measurement or (and) turning mechanism for automatic turning of eggs

The air inside a still air incubator is circulated by convection. As the air is heated it expands and rises to the top of the incubator. The amount of airflow achieved in a still air machine is therefore determined by the ratio of air temperature inside the box to outside. The lower the air temperature outside the box the greater the airflow inside. To achieve good air circulation, air inlets are usually positioned in the base and top of the incubator

**Cabinet Temperature and Humidity Difference.

*Forced Draft Incubator

The forced draft machine was developed to overcome temperature gradient problems throughout the incubator. In a forced draft incubator, a fan is used to circulate the air, which gives a uniform temperature throughout the machine. The air temperature surrounding the egg is therefore constant and positioning of the thermometer and temperature sensor are less critical. Eggs, too, can be of differing size and set in trays at different levels. Using a forced draft incubator also allows the use of a Wet Bulb Thermometer, which can be used for the accurate reading of humidity. It is of more importance to control humidity in a forced air machine to prevent the higher airflow drying the eggs.

**Forced Draft Incubator

*Contact Incubators

Contact incubators are a new generation of machines designed to mimic natural incubation much more closely Contact Incubation mimics the natural incubation process that occurs in the nest. The most striking difference between natural and artificial incubation is the fact that the natural parent provides warmth by contact rather than surrounding the egg with warm air. This may not at first sight seem significant but important research studies carried out by J. Scott Turner at New York State University and the University of Cape Town has revealed major unsuspected differences in thermal behavior of eggs incubated by contact rather than convection.

Crucially, eggs in a forced draft incubator have near uniform temperature throughout incubation; there will be some increase in embryonic temperature towards the end of incubation as a result of increased metabolism but otherwise the whole egg will remain near incubator air temperature. By contrast, eggs incubated naturally or by contact, have significant temperature differences. Heat is entering the egg over a relatively small brood patch, which is therefore warmer than other regions of the egg and is being lost from most of the remaining shell area.

*Contact incubators

Incubating Conditions

The condition of incubator is very importance element. Poor results are most commonly produced with improper control of temperature and/or humidity. Improper control means that the temperature or humidity is too high or too low for a sufficient length of time that it interferes with the normal growth and development of the embryo. Poor results also occur from improper ventilation, egg turning and sanitation of the machines or eggs.

The components than must be control in the incubator are temperature, humidity and ventilation. The turning of eggs in the incubator must also be controlled.

*Temperature control and its effects

The temperature must depend on the types of egg. In order to hatch a good percentage of fertile eggs, an incubator must be able to maintain a constant temperature. Though different sorts of eggs require different heat levels, most will grow and hatch well at 99 to 101°F. Sure, that does sound imposingly precise, but such accuracy isn't all that difficult to achieve.

Incubation temperature is one the most critical factors and the optimum temperature is 37.5-37.7˚C during the development stage and 36.1-37.2˚C during hatching period (Decuypere et al., 2001; Meijerhof, 2009). In the word of more specialized, egg shell temperature affects embryo development and chick quality (Lourens, 2003). The egg shell temperature is an indicator of embryo temperature and it is affected by breeder age, embryonic development stage, heat production by embryo, heat transfer between egg and envrionment, air temperature in seter and hatcher, air velocity and relative humidity (Meijerhof and Van Beek, 1993, Tona et al., 2004; Lourens et al., 2006; Hamidu et al., 2007; Molenaar et al., 2010).

In large scale hatcheries, during the second stage of incubation period especially after 9th day of incubation, optimum temperatures ranges could not be achieved because of excessive heat production by developing embryos (Nichellmann et al., 1998; Lourens et al., 2007; Meijerhof, 2009). It suppresses heart, crop, gizzard, liver, intestine development and also yolk sac absorption. Embryos with high growing rate are sensitive to temperature fluctuations. Small deviations from optimum ranges have negative effects on hatchability and hatchling quality (Taylor, 2000; Molenaar et al., 2010). In case of providing optimum temperatures, yolk sac is absorbed exactly by embryos, navel of chicks is closed well, thus the number of good quality chicks increase and early stage chick mortality originating from uncovered navel or yolk sac and E. coli infections can be reduced (Meijerhof, 2003). Fluctuations in egg shell temperature results in economic losses in broiler production with negative effects on post-hatch performance and slaughter yield (Wilson, 1991; Lourens and Van Middelkoop, 2000), because of the regressive impacts on organ development (Shafey, 2004) and chick growth performance (Michels et al., 1974; Decuypere, 1979; Geers et al., 1983).

In higher incubation temperatures, chicks hatch earlier and the navel problems and organ abnormalities could occur more than optimum temperatures. Deeming (2000) reported that higher incubation temperatures increase oxygen requirements of embryos. By much more burning of oxygen, waste heat production and also eggshell temperature show an increase (Lourens, 2003). As a result of this, growth rate is deteriorated, utilization of albumen proteins is repressed and embryo goes under stress. At hatching, higher late term embryonic mortalities, lower hatchability, worse quality of chicks and post-hatch early period chick mortalities could be occurred (Deeming, 2000; Lourens et al., 2005; 2007).

Deeming (2000) also reported that lower incubation temperatures result in chick death in pip stages. It causes longer incubation period and delayed hatching. Additionally, abnormal incubation temperatures induce twist toes and this abnormality affects negatively broiler performance in later. Lately, the effects of different incubation temperatures in a certain stage on embryonic development, chick quality and broiler performance have been investigated by different researchers. Joseph et al. (2006) compared lower temperature (36.6 ˚C) to control (38.1 ˚C) from 1st day to 10th day of incubation and found lower hatchability and rate of saleable chicks in lower temperature treatment than control. Hatchability of total eggs and rate of saleable chicks were found as 87% and 81% in lower temperature treatment, 91% and 87% in control. In the second part of this research, Joseph et al. (2006) investigated that the effects of high incubation temperature (39.4 ˚C) in the same period. It was found that higher temperatures had an increasing effect on hatchability and found as 90% and 88% in control.

However, it had similar effects on rate of saleable chicks in control (88%) due to higher number of cull and abnormal chicks in higher temperature treatment than control. They also found that while lower temperature during development stage resulted in higher chick hatching weight and shorter chick length, higher temperature during hatching period resulted in lower chick hatching weight, but similar chick length compared to control.

In another study, Hulet et al. (2007) investigated that the effects of low (37.5˚C), control (38.6 ˚C) and high (39.7 ˚C) temperatures during hatching stage of incubation on broiler performance. As a result, they found that differences in chick hatching weight reflected the final broiler weight. The highest chick hatching weight was found in high temperature group as 43.1 g. In low temperature and control group, hatching weight was determined as 41.1 g and 42.2 g. At the end of rearing period, higher final broiler weight was found in control (2263.3 g) than others (low: 2213.8 g, high: 2165.7 g). Also, there were no significant differences for carcass weight and carcass yield among treatment groups.

Suboptimal incubation conditions also cause deficiencies in development during embryonic stage and in broiler growth performance during rearing period (Meijerhof, 2003). Hill (2002) reported that optimum incubation temperature is required for competence development of organs and growth, if not, it suppresses development, growth and survival rate. Wineland et al. (2000a, 2000b) emphasized that heart is one of the most affected organs by suboptimal eggshell temperatures and it causes changes in relative heart weight at hatch. It results in suppression of cardiovascular system during embryonic development. As a result of this, a metabolic disorder called ascites, induced by abnormal incubation temperatures, occurs especially during 5th and 6th weeks of rearing and causes serious economic losses (Coleman ve Coleman, 1991).

*Humidity control and its effects

The other important factor affecting chick quality and incubation results is relative humidity. Lundy (1969) reported that optimum relative humidity could be between 50-60% for optimum incubation results. During the incubation, optimum egg weight loss should be approximately 12-14% (Ar and Rahn, 1980). The egg weight loss between 6.5-14% until internal pip stage is too important to ensure an adequte air cell size and to begin lung respiration (Molenaar et al., 2010). Varios factors like temperature within setter, relative humidity, egg shell quality and egg weight influence egg weight loss. While inadequate egg weight loss during embryonic development causes oedema in chicks, excessive egg loss weight results in dehydration and also higher number of small and cull chicks (Lapao et al., 1999; Collins, 2000; Molenaar et al., 2010; Taylor, 2000). According to Taylor (2000), inadequate egg loss weight causes increment of egg albumen, higher percentage of late term embryonic mortality, the higher number of chicks with uncovered navel and red hocks.

During incubation, in lower humidity levels, hatching chicks could be small, dehydrated and sticky (Deeming, 2000). Uncovered navels is one of the most common problems in higher relative humidity levels. It inhibits utilisation of yolk sac, induces yolk sac infections, increases first week chick mortalities. Chick hatching weight is an indicator of chick quality and it depends on egg weight and also egg weight loss during incubation. The effects of relative humidity levels on chick quality and incubation results have been investigated by some researchers. Bruzual et al. (2000) searched the effects of three different relative humidity as 43%, 53% and 63%. They found the highest hatchability of fertile eggs as 89.1% in 53% relative humidity group and the highest chick hatching weight in 63% relative humidity group. In 63% relative humidity groups, late term embryonic mortalities was found significantly higher than other groups. Itwas explained that during late term of incubation, the oxygen requirements of embryos increased, accordingly increasing of water vapor and decreasing of oxygen partial pressure in seter. Similarly, Hamdy et al. (1991) practised two different relative humidity as 45% and 55%. As a result, they found that higher humidity levels cause an increase in chick hatching weight.

Rarely is the humidity too high in properly ventilated still-air incubators. The water pan area should be equivalent to one-half the floor surface area or more. Increased ventilation during the last few days of incubation and hatching may necessitate the addition of another pan of water or a wet sponge. Humidity is maintained by increasing the exposed water surface area.

The relative humidity level during incubation varies according to numerous parameters: breed, age of egg, age of flock and weight of egg, washing prior to incubation and the type of machine. However, it is important to keep in mind that excessive humidity causes pipping difficulties as the air cell is not sufficiently developed and therefore an increase in the percentage of pipped but unhatched eggs. As fluid resorption is poorer, chicks are larger, even swollen, and weaker. Finally, the risk of omphalitis is increased. Alternatively, insufficient humidity causes dehydration, leading to smaller chicks with sparse down. Shell membranes stick to the embryo and hatching difficulties can also be observed. (CEVA Animal health, Asia Pacific, 2007)

Using a wet-bulb thermometer is also a good way for determining relative humidity. The wet-bulb thermometer measures the evaporative cooling effect. If the wet and dry bulb read the same temperature, humidity is 100%. The greater the evaporation taking place, the lower the temperature reading on the wet-bulb thermometer and the larger the spread will be between the wet and dry-bulb readings. The range of wet bulb temperature required is 26.5 - 32˚C [12]. To make a wet-bulb thermometer, add a cotton wick to the end of a thermometer. Then place the tail of the wick to the end of a thermometer. Then place the tail of the wick in water. The cotton then absorbs the water. As the water evaporates from the cotton it causes a cooling effect on the thermometer.

Source

Plagiarism is the copying & pasting of others work without giving credit to the original author or artist. Plagiarized posts are considered spam.

Spam is discouraged by the community, and may result in action from the cheetah bot.

More information and tips on sharing content.

If you believe this comment is in error, please contact us in #disputes on Discord