Wood is extraordinary. It looks decent as a building material. It develops ideal out of the ground. Yet, contrasted with things like solid, marble, and steel, it's not too solid. All things considered, it didn't used to be, in any case. Researchers have now made a "super wood" that is sufficiently solid to stop a shot.

Nature of Titanium Strength

This isn't the world's initially designed wood. Odds are, you've got some in your home right at this point. Plywood, fiberboard, and particleboard are altogether made by compacting littler bits of wood into a solitary piece that is more grounded than its composite parts. Of those three, plywood is the most grounded, since it's made with thin layers whose grain is set at opposite edges. You don't need to stress over the wood being feeble along the grain on the grounds that each layer is sandwiched between two others running the other way. Be that as it may, on the off chance that you need to stop a shot, we wouldn't suggest hopping behind a plywood boundary. For that, you'll require super wood.

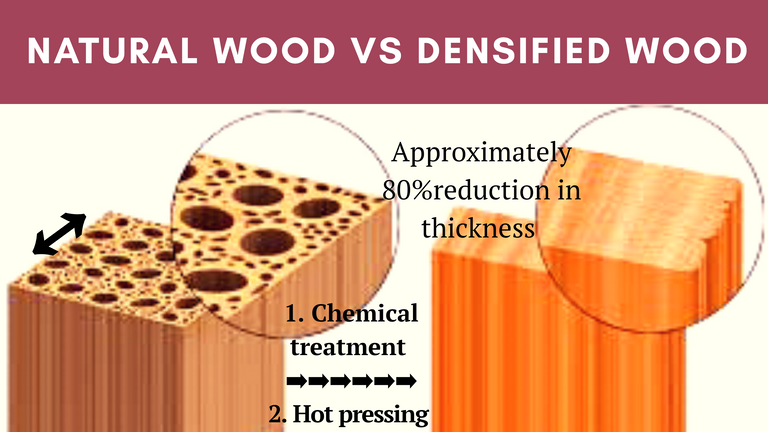

It was shockingly simple and shabby to make this new sort of wood. Like such a large number of supervillain inception stories, everything begins with a compound shower. In the first place, you heat up the wood in an answer of sodium hydroxide and sodium sulfite. That evacuates a great part of the wood's lignin and hemicellulose, two polymers that harden the plant's cell dividers, however leaves another polymer, cellulose, in place. This piece of the procedure isn't vastly different than the initial step of making paper. It may appear to be irrational, yet evacuating or debilitating these polymers is the way to making ultra-solid wood.

The following stage is to begin compacting. You subject the wood to enough strain to fall the cell dividers completely, at that point you turn up the warmth a bit and keep the weight going. Unhindered by the phone dividers, the hydrogen particles of the cellulose start to shape capable compound bonds with their neighboring iotas, making the material denser and more grounded than at any other time. What's more, when we say more grounded, we mean it — the wood progresses toward becoming 20 times stiffer, 10 times harder to break, and 50 times more impervious to pressure. It's not only more grounded than steel; it's more grounded than some front line titanium compounds. Better believe it, we'd say "super wood" is a truly reasonable evaluation.

The Future Is Clear

There's a great deal we could do with a substance that is nearly as shabby and simple to deliver as paper, more grounded than titanium, and lightweight to boot. Here's one thought: body protection. The super wood isn't exactly as solid as Kevlar, however it's around 20 times less expensive. It may likewise turn into a most loved for building autos and different vehicles since it can give the fuel-proficient advantages of a lightweight casing without the ensuing ascent in cost or ecological effect of plastic.

However, the way a few scientists see it, the staggering quality and solidness of the wood is just the start. Liangbing Hu, the lead scientist behind this super wood, could control the material in maybe a much all the more striking route in 2016, when he stripped out the lignin (which likewise loans wood its shading) and supplanted it with another polymer called methyl methacrylate — otherwise called Plexiglas. The outcome? Something straight out of "Star Trek": straightforward wood. So your future auto may not simply be riding on a wooden edge. It could have a wooden windshield also.

Kindly give credit to the source of your image. You can use this tool https://steemitcuration.appspot.com/imageformat

even if the photo was edited by you is it still necessary to give credit? thank you in advance for the answer