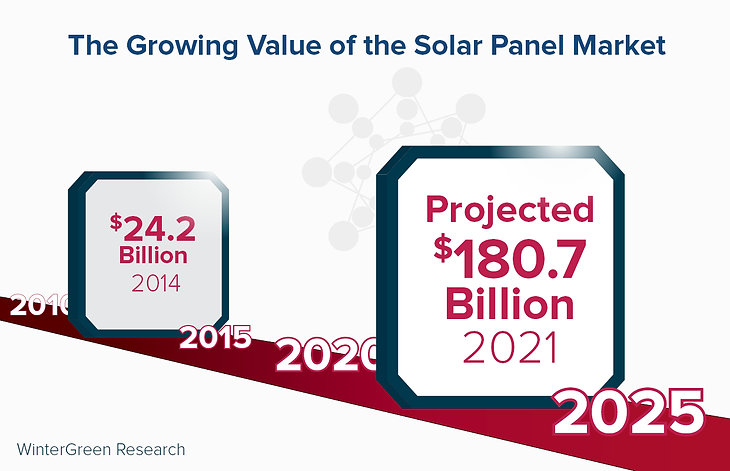

Solar power is not only amazing for the environment, but also a huge opportunity for intrapreneurs. The solar industry is growing rapidly turning into quite a profitable business. The main obstacles in recent years, have been the cost of renewable systems, their efficiency and their ability to store the energy they produce. Scientists have been trying to solve these issues, hoping to make this technology viable.

The global energy market is projected to grow to over $10.4 trillion by the year 2020.

Furthermore, the International Energy Agency (IEA) expects renewable energy to be "the largest single source of electricity growth over the next five years."

By 2040, renewables will command 60% of new capacity and 2/3 of power investment globally. As global population surpasses 7.5 billion people, additions to the global sustainable energy portfolio will top 700 GW or 26% of the world's power capacity. As international economies make a more conscious effort to shape the way we generate energy, the stage is set for renewables to become the primary method of powering the world.

The Solar Power "sector" is evolving rapidly, with the presence of Elon Musk, who pioneered the development of household battery storage devices called The Tesla Powerwall. Bringing the ability to store solar energy at home to the mainstream was a significant step forward, which has inspired other companies to produce their own versions.

One of the biggest issues untill now, has been the the cost, which for a long time suppressed the market of renewable energy. However, now things are changing! A company called Rayton Solar is hoping to radically alter the industry by cutting the cost of production by a 60% while increasing efficiency of solar panels to 24 %!

The technique Rayton Solar is using, utilizes a new cutting technique to produce incredibly thin sheets of silicon.

Approximately 100 and 50 times thinner than what is currently achieved, which means Rayon Solar can produce far more panels from the same volume of material than other companies!

The standard industry manufacturing process wastes half the raw silicon block due to the saw blade that is used to cut silicon. Rayton Solar's manufacturing technology is a zero waste process that represents a revolutionary new step for the solar industry.

The Process

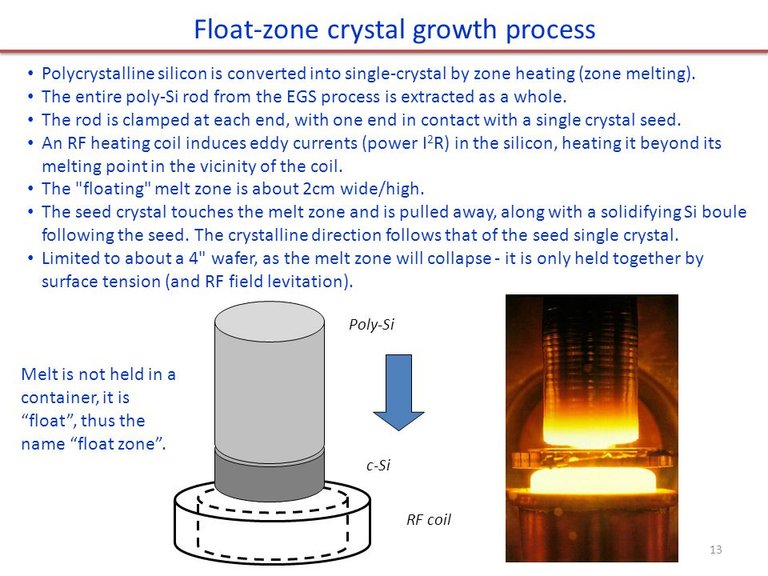

This technique allows the use of higher grade silicons, for example like the float-zone silicon currently used by NASA, which has a far higher efficiency compared to other market varieties.

Float-zone silicon is a high-purity alternative to crystals grown by the Czochralski process. The concentrations of light impurities, such as carbon and oxygen, are extremely low. Another light impurity, nitrogen, helps to control microdefects and also brings about an improvement in mechanical strength of the wafers.

All this cuts a huge part of the cost for the consumer. Which means more and more people will be installing solar panels. It would also lower the installation costs as 25 percent fewer panels would be needed. In terms of commercial use, this means that solar farms would need much less land.

We may say that the tide has already turned, fossil fuel industry is dying. It will take years to find out whether this is true, but what is certain is that renewables are looking like a far more logical investment for the future!

Official Video

Thanks for reading! Feel free to follow, vote and Re-esteem if you find it useful. You can find more of my articles here:https://steemit.com/@sungazer13

Source: http://www.raytonsolar.com/

http://www.iflscience.com/technology/new-solar-innovation-cuts-costs-by-60-while-increasing-efficiency-by-24/

Hopefully the company would take off really well. We need to be sustainable if we need a future that is bright.

That's really good news.

Future energy

Thanks for posting

Energei solar merupakan energi terbarukan, karena masa depan energi alami dari hasil alam akan habis dengan sendirinya, jadi dengan adanya cahaya matahari yang energinya bisa disimpan menjadi energi listrik, maka tidak ketergantungan lagi dengan hasil alam yang mau punah

Resteemed to over 5500 followers and 100% upvoted. Thank you for using my service!

Send 0.100 Steem or 0.100 Steem Dollar and the URL in the memo to use the bot.

Read here how the bot from Berlin works.

@resteem.bot

Resteemed by @steemvote - send only 0.5 SBD to get your post resteemed to 2K follower and receive Bonus-Upvotes

Excellent post @sungazer13. Amazing technology. Thanks for sharing.

Thanks for reading and commenting !

You cannot compare the cost of a research project and costs of industrial production. 200 micron is already very thin. Several attempt have been made in the past to print thinner layer. I hope they will be successful but it is a little bit early to say they will be 60 % cheaper.