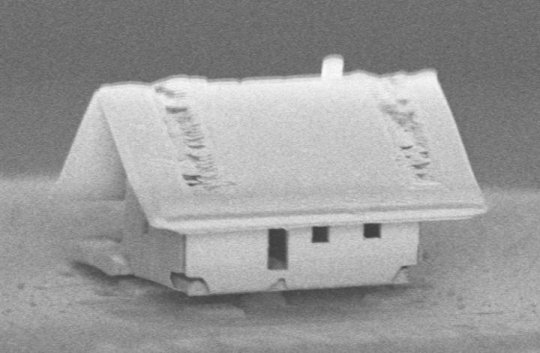

Nanorobotics team demonstrates their new capability to manufacture optical nanotechnologies.

A French nanorobotics team from the Femto-ST Institute in Besançon, France, assembled a new microrobotics system that pushes forward the frontiers of optical nanotechnologies. Combining several existing technologies, the μRobotex nanofactory builds microstructures in a large vacuum chamber and fixes components onto optical fiber tips with nanometer accuracy. The microhouse construction, reported in the Journal of Vacuum Science and Technology A, from AIP Publishing, demonstrates how researchers can advance optical sensing technologies when they manipulate ion guns, electron beams and finely controlled robotic piloting.

Until now, lab-on-fiber technologies had no robotic actuators for nanoassembly, so working at this scale inhibited engineers from building microstructures. This innovation allows miniaturized sensing elements to be installed on fiber tips so engineers can see and manipulate different components. With this advancement, optical fibers as thin as human hair can be inserted into inaccessible locations like jet engines and blood vessels to detect radiation levels or viral molecules.

"For the first time we were able to realize patterning and assembly with less than 2 nanometers of accuracy, which is a very important result for the robotics and optical community," said Jean-Yves Rauch, an author on the paper.

The French engineers combined all the technological components for nanoassembly -- a focused ion beam, a gas injection system and a tiny maneuverable robot -- in a vacuum chamber, and installed a microscope to view the assembly process. "We decided to build the microhouse on the fiber to show that we are able to realize these microsystem assemblies on top of an optical fiber with high accuracy," Rauch said.

Building a microhouse is like making a giant dice from a piece of paper, but nanoassembly requires more sophisticated tools. The focused ion beam is used like scissors to cut or score the silica membrane "paper" of the house. Once the walls fold into position, a lower power setting is selected on the ion gun, and the gas injection system sticks the edges of the structure into place. The low-power ion beam and gas injection then gently sputters a tiled pattern on the roof, a detail that emphasizes the accuracy and flexibility of the system.

In this process, the ion gun had to focus on an area only 300 micrometers by 300 micrometers to fire ions onto the fiber tip and silica membrane. "It's very challenging to pilot the robot with high accuracy at this cross point between the two beams," Rauch said. He explained that two engineers worked at multiple computers to control the process. Many steps are already automated, but in the future the team hopes to automate all the robotic stages of assembly.

Now, using the μRobotex system, these engineers are constructing functionalized microstructures to detect specific molecules by attaching their microstructures onto optical fibers. The nanorobotics team is hoping to push the limits of the technology further still, by constructing smaller structures and fixing these onto carbon nanotubes, only 20 nanometers to 100 nanometers in diameter.

Hi! I am a robot. I just upvoted you! I found similar content that readers might be interested in:

https://www.sciencedaily.com/releases/2018/05/180518102729.htm