Hi,

yes the first one.

However, to be honest this is not my preferred way to create knobs.

You have to be very carefully and the whole process while take some time.

You need

- the right acrylic (better cast than extruded)

- a drill press for a perfect and consistent 90-dregree angle during the whole cut.

- very low speed of the drill

- very low pressure (hole saw to the acrylic)

- cut the material in small steps, then raise the saw, wipe of the chips and then go for the next mm

- maybe a coolant

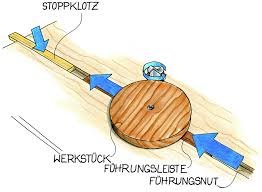

In my opinion the better way to create round things, is to use a router. The cut quality is also good, but its easier and faster. I tried this last year with a 30mm circle. Works very well.

Something like this.

Source

(Sorry for the German example)

np, I manage to understand German. Talking is worse.

I just use a lasercutter for round things ;-)

Those drill saws seem to wobble to much. Probable you have them in different price classes.