Hello everyone,

some time has passed since the last update.

No, the project is not dead, but I had a lot of

work with a new way of documentation.

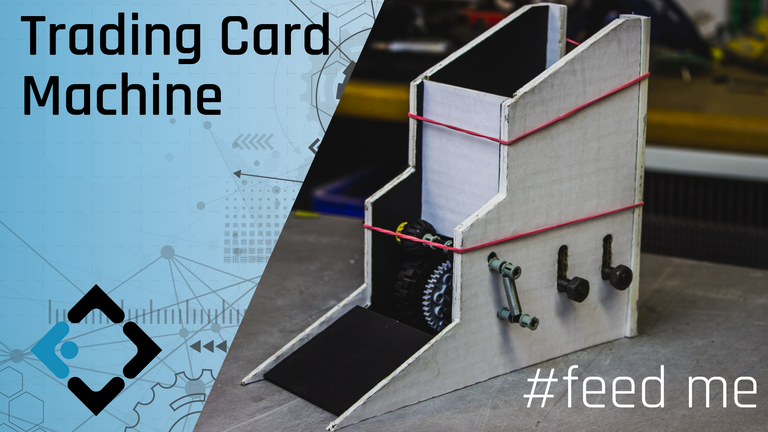

I worked on a video that shows you the

building process of the Card Feeder.

And what should I say ..... it's so complex and

time consuming. It's insane.

I spent hours and days on my camera and on

my computer. I learned a lot, it was very

interessting and I also think, that I will produce

more videos in the future.

This means also, that I don't had the time to

work on the Card Sorter.

But now,... the video is finished.

I like it, but it's not perfect. There is enough

room for improvement.

How do you like it?

Do you have questions or suggestions?

Tips for a better video?

Thanks a lot.

What’s next?

I'm working on the "offical" article about the card feeder. :)

And I start to work on the Card Sorter

Servus and cu next time!

Hi theguymasamato,

Visit curiesteem.com or join the Curie Discord community to learn more.

Hi curie,

thanks. That means a lot to me.

Wish you also a nice day.

Nice project!

Would also be nice to have a model to be 3d printing it :-D

Wouldn't it be better adapted for laser cutting ?

Given we're talking near-exclusively flat pieces

Plus with Laser Cutting you could engrave a cool design on each side of the Card Feeder XD

3D printing could be used to extend the design's sides to make an awesomely shaped version that's much more stable, though, so there's probably potential with both Laser Cutting and 3D printing !

Hey pbock,

yes you're right.

One problem, I don't have a laser. :)

But, I own a CNC. I could cut the shapes with it.

cu

Sure Laster cutting would speed up some parts and would give you the option to use different materials. But its not so big that you could not print it and 3d printer are more spread...did you get yours by now ? I still haven't got my price from MyMiniFactory.

nope... they've gone silent since I found that update on their indiegogo page saying they had a 1 month delay (so technically delivery date would have been mid/end October). Tried sending MakeX's MIGO team an email but no answer yet, and it's been more than a month since the liaison from MyMiniFactory has answered my emails X/

have they at least been keeping you updated on the prize, or have thye just gone silent too ?

True, 3D printers are easier to acquire and more widespread, so 3D printing adaptation would probably be the easiest to go with first.

What I think the 3D printed version would excel at would be to have sculpted parts on the exterior parts, like having it look like an actual old tower that spews cards or something XD

Yea good idea with the tower :-D

Just send out an email to myminifactory asking if they have any updates for me.

Hi drmake, thanks.

When the scanner and the sorter is finished I will think about the final design and material. 3d printing is one option, because I have created already the 3d model in Fusion360.

Yea would be a interesting machine to print !

Thanks for using eSteem!

Your post has been voted as a part of eSteem encouragement program. Keep up the good work! Install Android, iOS Mobile app or Windows, Mac, Linux Surfer app, if you haven't already!

Learn more: https://esteem.app Join our discord: https://discord.gg/9cdhjc7

Thanks for your vote.

Great video, looks very professional!

Personally, I prefer text for this type of content, so I particularly liked the small text boxes. ;D Also the "close-ups" eg. when cutting the cardboard were great. You feel a bit like being part of it and you are animated to replicate it. Maybe I would even add a point at the end where you can hear the sound of the device in operation.

One question I have: The mechanics is indeed driven by a servo. Is this "hacked" or does it go back to its starting position after each ejection of a card?

By the way, the trick with the wood to reinforce the cardboard, I have directly noticed. :D

I'm looking forward to a final video / article with the finished feeder.

Hello schabenstolz,

thanks for your tips, I appreciate it.

I will do my best to consider it in the next video.

This video is an additional documentation, but it will not replace the written text. I just want to finish everything so that I can show it all together in the final text post. Drawings, animations, photos and the video.

Yes, with a servo. No, it's not hacked. It is a FEETECH FS90R Micro Continuous Rotation Servo

You are welcome.

I'm looking forward to the article and thanks for the link, i did not know that such servos exist. :x

You are real handy man! If you are doing such stuff with cardboard and legos with a little bit of electronics, I can imagine you can create impressive stuff using real materials, like probably wooden furniture, I like how you created that cardboard case and thought about every single side, measured and checked and rasp. It was worth because the end result is really good. I wish our children could learn those skills in school it would be helpful in their life too.

Thank you so much. I feel flattered.

It was a lot of work, maybe a little bit over the top, because it's only a test.

But I learned a lot. This was my first time working with cardboard.

If there will be a school subject about "making", I want to go back to school. :)

Join our Discord Channel to connect with us and nominate your own or somebody else's posts in our review channel.

Help us to reward you for making it ! Join our voting trail or delegate steem power to the community account.

Your post is also presented on the community website www.steemmakers.com where you can find other selected content.

If you like our work, please consider upvoting this comment to support the growth of our community. Thank you.