They are crystals of different compositions that are used as an instrument to measure the amount of ionizing radiation to which they have been exposed.

In the thermoluminescent materials used, in dosimetry, thermoluminescent emissions are essentially processes related to the presence of impurities that have been artificially introduced into the network of the matrix material (dopants). These impurities generate specific energy levels (traps) in the band of forbidden energies located between the valence band and the conduction band that do not exist in the pure material. These new levels can be occupied by charge carriers, electrons or holes, released during irradiation. In insulating materials the band gap is usually quite wide, 6 eV or greater, allowing the presence of a wide variety of traps associated with various complex defects in which precisely impurities involved with which the material has been doped.

In effect, during irradiation the material absorbs a certain amount of energy that results in the creation of electron-hole pairs, exciting electrons to the conduction band and leaving their respective gaps in the valence band. Both types of charges can move through their respective bands and after a short interval of time they recombine (early recombination) either by radiative or non-radiative channels [1]. The existence of these intermediate levels in the band gap causes an alternative channel to open through which part of those electrons or gaps generated after irradiation are stabilized by delaying or preventing their immediate recombination.

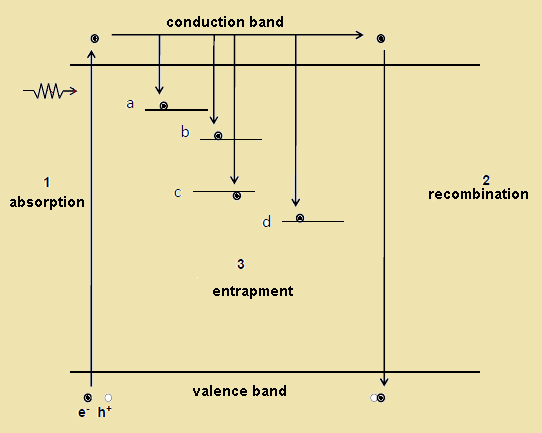

The entire process is represented schematically in Figure 1. The absorption of energy is represented by step 1: an electron is carried to the conduction band leaving a gap in the valence band. The early recombination (step 2) represents the almost immediate return to the ground state prior to irradiation. The entrapment of part of the charge carriers (electrons in this case) is step 3 of the figure. In short, these intermediate levels or traps serve as places where a small fraction of the energy absorbed by the material of the radiation field can be stored once the irradiation has ended.

Figure 1. Thermoluminescence process. [1]

It is possible to find structures (matrix network and impurities) in which there is a distribution of these impurity levels close to the conduction band. In such a case, the charges trapped in the conduction band are again excited by simply supplying a small amount of energy in the form of heat, that is, by raising the temperature of the material.

If the temperature is gradually increased, the charges trapped in the traps closest to the conduction band will be excited in the first place. These will reach the conduction band at lower temperatures than those loads that have been trapped in deeper traps and will obviously need a higher energy to be released. Once in the conduction band and, with the material at high temperature, the most probable process is the recombination that again has the possibility of following radiative and non-radiative channels. In good TL materials, radiative recombination is favored by the existence of luminescent recombination centers, also associated with specific doping impurities.

This whole process takes place during the reading stage of the dosimeter and is represented in Figure 2. Step 4 of the figure is the thermally stimulated release of trapped charges followed by the diffusion of electrons by the conduction band and gaps in the band of valence. Finally step 5 shows the radiative recombination that takes place in the recombination center and that is what generates the thermoluminescence curve.

Figure 2. Reading process in the thermoluminescence. [1]

In summary, this simplified scheme can be understood as the termoluminescence in terms of two types of centers, traps and recombination centers. The traps act by storing information relative to the absorbed dose of the radiation field and the recombination centers transforming it into TL photons during reading.

The shape and structure of the TL curve obtained in the reading is determined by the process of liberation-recombination of the charges of different trapped signs, in this scheme electrons and holes. For deep traps, such as c or d in Figure 2, the probability of escape of their traps at room temperature is very low and the associated peaks are stable at that temperature. The traps a and b of this figure, given their proximity to the conduction band, will require less energy to be released and their probability of escape will be greater and may not be stable at room temperature. For this reason the low temperature TL peaks are not used in dosimetry because the dosimetric information is not stored with sufficient thermal stability [1].

As the radiative recombination follows the release of the charges, the intensity of the light detected during the reading will also have the shape of a peak. In Figure 2 each thermoluminescence peak is associated with a different and independent trap and each process can be described phenomenologically as just done and the composition of all of them would lead to a complex thermoluminescence curve, very common in the different thermoluminescent materials.

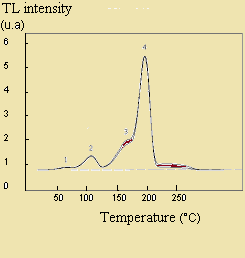

The LiF: Mg, Cu, P (TLD-100H) material that has been elaborated for dosimetric use in the form of powder, polycrystalline in different presentations, either chip's, circular or rod's type, used in my research work . The typical brightness curve of LiF: Mg, Cu, P, intensifies at peak 4 near 200 ° C, with a lower intensity of peaks at low and high temperatures. Peak 4 is the main peak in dosimetry, peak 5 is the most problematic in terms of the residual signal and the consequent capacity to reuse this material (Figure 3) [2].

Figure 3. Representation of the LiF brightness curve: Mg, Cu, P. [2]

REFERENCE

[1] Muñiz Gutierrez, J. L. (1999). "Experimental methods of postal dosimetry for quality control in radiotherapy based on LiF: Mg, Ti (TLD-100) and LiF: Mg, Cu, P (GR-200). Application of numerical methods to the analysis of thermoluminescence curves ". Madrid Spain: Complutense University of Madrid Faculty of Physical Sciences Department of Materials Physics.

[2] Mckeever. S, (1995). "Thermoluminescence dosimetry materials: properties and uses". Nuclear Technology Publishing. Ashford, YW, England. P. 55-57.