Hello, My Steemit friends! I hope you all are doing well!

With learning, reading, we can find out all good knowledge about Mechanical Engineering. The catalytic converter that works in the carburetor system is influenced by the octane content of the fuel so that we can know how to work on the vehicles we have and know how to overcome them in case of damage.

A little discussion from me about working in the carburetor system is influenced by the octane content of the fuel in the engine.

The volume of fuel produced in the combustion chamber in the engine is very influential for the needs of the engine in order to get efficient combustion results, this discussion is strongly influenced by the performance of the piston because the supply of fuel to the combustion chamber is sucked from the tidal piston, therefore the volume of fuel must be in accordance with the requirements needed by the engine.

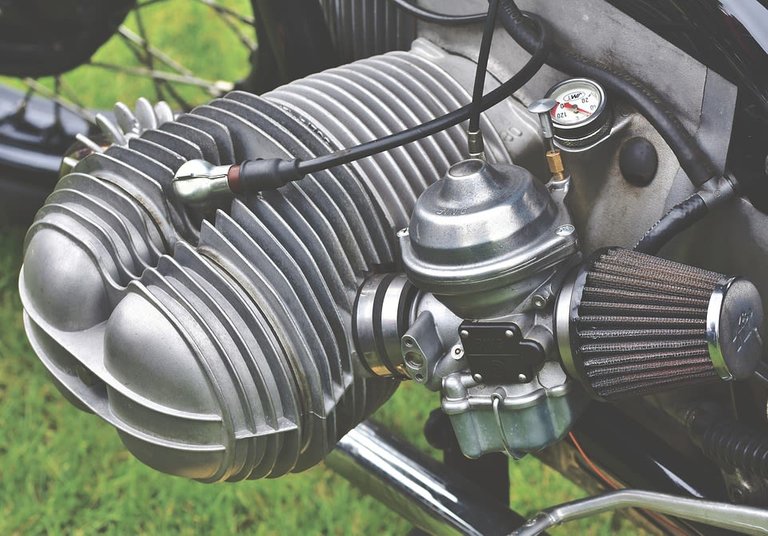

Every engine cannot run without a carburetor or injection system on a vehicle, in the engine working principle, the duties and functions of the carburetor and fuel injection are the same, the task of mixing clean air with fuel. What's different is how it works, below we learn a little difference in how the carburetor and injection systems work.

Work System Differences

In a carburetor, the piston action step produces fuel suction with air in the combustion chamber. In the injection system, the mixing of fuel with air is carried out by the injector at the request of the ECM which requests a signal from the sensor then spreads throughout the engine and exhaust.

When the engine is cold, the engine releases a rich mixture of gasoline to start the engine at cold temperatures. In the carburetor, a choke is needed to produce fuel into the engine combustion chamber, In contrast to working with an injection system, the temperature sensor will report a cold engine temperature so that the ECM receives an injector to enrich the gasoline mixture.

So, what is the function of Catalytic Converter?

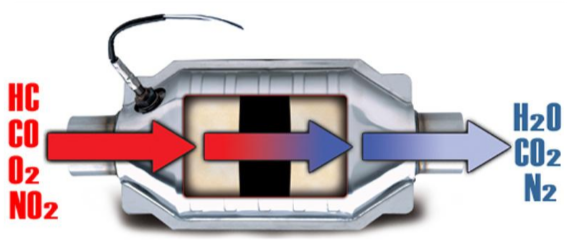

Catalytic converters are made of palladium metal, so when the flue gas touches the metal, a chemical reaction occurs to remove some content or compounds such as hydrocarbons.

Based on catalytic converters, there are 4 types of catalytic converters:

- Catalytic oxidizing system..

- Two-bed catalytic converter.

- Three-way catalytic converter system.

- Reducing catalytic conversion systems.

Oxidizing catalytic system

The working process of the oxidizing catalytic system by accelerating the oxidation of CO and HC, the commonly used oxidizing catalytic system is platinum or palladium operated under excessive oxygen conditions, with oxygen feed from secondary air injection, secondary air injection.

For this type of oxidizing catalytic system mounted on the carburetor.

In an oxidizing catalytic system, excess oxygen oxidizes CO and HC. Here's the reaction:

· HnCm + (m+n/4)O2 --> mCO2 + n/2 (H2O).

In the above reaction process, the NOx gas produced cannot be reduced so that another catalyst needs to be added. The disadvantage of this oxidizing catalytic system is that it is easily contaminated by lead, sulfur, and phosphorus.

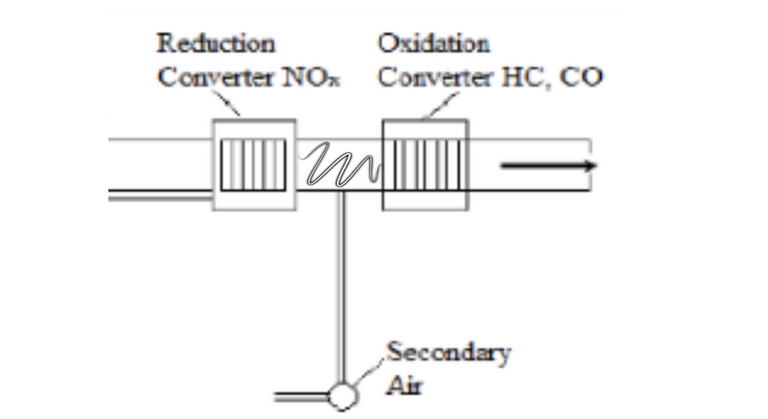

Dual-bed catalytic converter

With this converter process, there is a very high probability of simultaneous reaction to reduce NOx, CO, and HC. The drawback, the engine must be operated in the rich range so that fuel consumption becomes high.

Source (Unimus Student Research Resources)

Reduction and oxidation chemical reactions are complementary and interdependent so that the process goes well, it needs a constant fuel-air mixture under all engine loading conditions although this cannot be controlled with mechanical fuel mixing equipment.

Thus the simultaneous reduction of CO, HC and NOx pollutants will require a closed-loop system that continuously monitors the exhaust gases. In a closed-loop system, there are deviations that occur if the composition of the exhaust gas in the stoichiometric range then spontaneously changes the loop system.

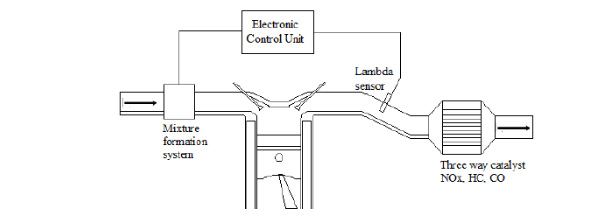

Three-way catalytic converter system

The three-way catalytic converter system is a flue gas processing converter that produces exceptional quality waste in terms of relatively clean gas quality.

Source (Unimus Student Research Resources)

This three-way catalytic converter system is influenced by a computer-based fuel-air mixing system and simultaneous conversion into CO, HC and NOx pollutants and we can know that this three-way converter system is platinum and rhodium.

The reactions on the three-way catalyst platinum and rhodium are:

The above reaction needs to be made so that the ratio of oxidizing to reductant, is an electrolyte cell with ZrO2 which can be used as a buffer that can produce all pollutant sensors. This sensor consists of an electrolyte cell with ZrO2 which functions as a solid electrolyte. The output voltage serves to fill the oxygen content in the flue gas.

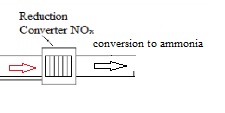

Reducing catalytic conversion systems.

NOx gas can be treated by an oxidizing catalytic system, but reducing the catalytic conversion system can be replaced with rhodium and ruthenium to accelerate the process of reducing NOx to N2 gas.

Source (Unimus Student Research Resources)

The reduction process of catalytic conversion systems can occur if there is excess reduction such as CO and HC, the process of conversion to ammonia because it can be changed again by the oxidizing catalyst to gas.

This is the type of combination between an oxidation type catalytic converter and a reduction type that operates in rich range conditions. There are two types to be injected, namely secondary water and secondary air on the catalyst.

Conclusion

Generally, vehicles have used catalysts and many problems occur due to lack of knowledge in driving down vehicles on the catalytic converter system. In this discussion you can find out the types of catalytic converters, making it easier for you to overcome them.

The catalytic converter system must use gasoline which has the best octane reserve, the carburetor system used by the fuel. If you use a poor octane composition, the catalytic converter is no longer effective, the volume of fuel must match the requirements required by the engine so that the piston produces a supply in the combustion chamber to produce efficient results.

Source

Azman Nicely Nasha/ @azman

Hello interesting content, the truth is that I've always been passionate about this kind of topics because I'm a car lover and I've always liked to modify them.

Friend you have problems with some images in your publication, some links are down and another image is copyrighted. I recommend you to correct these little details

Ok sir..

Thank you..

I will fix it in the next post..