Modern Manufacturing: Polymerization of High Density Polyethylene (HDPE)

Greetings to the entire STEEMIT community.

As a starting point, it is important to note that the modern world has emerged thanks to the mass development of the main principles of industrial manufacturing. It is precisely this revolution that has characterized the countries power in the world to take the economic advantage and social development. Polymerization is one of these principles of modern manufacturing that has provided an important impact due to its diverse application as a raw material for obtaining materials of high use and human consumption; such is the case of plastics, textiles, tools, industrial equipment, personal protective equipment, vehicle parts, machinery, among others.

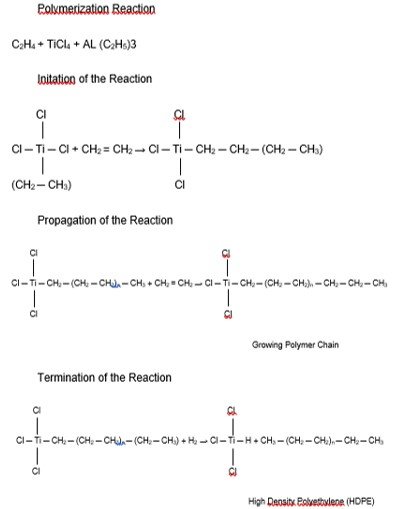

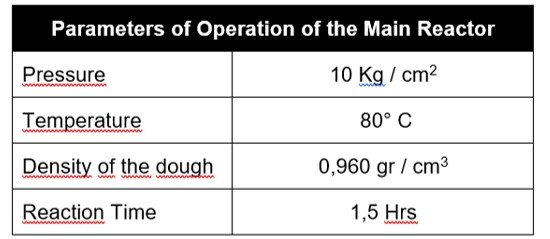

Polymerization is characterized as a reaction by which a polymer is synthesized from its monomers. Depending on the mechanism by which the polymerization reaction occurs to give rise to the polymer, it is classified as "step polymerization" or as "chain polymerization". In any case, the size of the chain will depend on parameters such as temperature or reaction time, each chain having a different size and, therefore, a different molecular mass, hence the average mass of the polymer. It is also worth noting that the main polymerization industrial processes are based on olefins developed by petrochemical research that starts from the fractionation of hydrocarbons such as natural gas and oil.

On this occasion I would like to provide a technical analysis of the industrial performance of high density polyethylene (HDPE) production; a semicrystalline thermoplastic polymer; by means of which the use of olefins is optimized to react it by addition with catalysts that open the molecular chain in its carbon double bond and form long reactive chains until the end and obtain the desired product. In this case, a diversified process is proposed according to two phases: Catalyst Preparation and Polymerization.

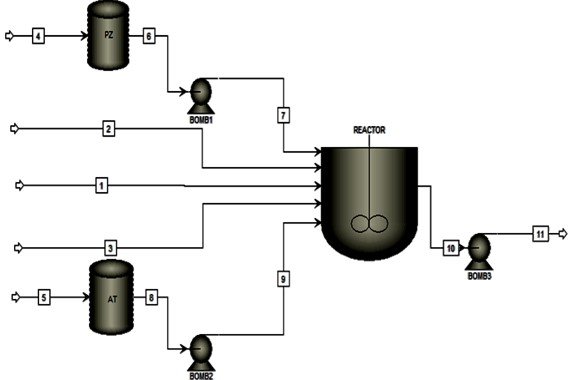

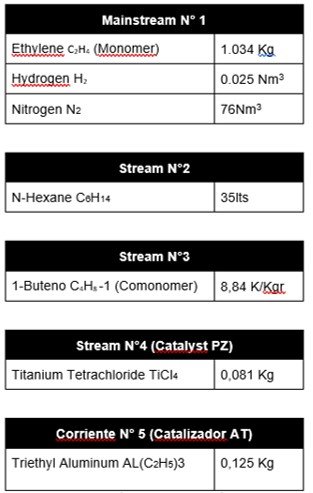

In order to achieve a polymerization production of approximately 1 metric ton (Tm) of high density polyethylene (HDPE), this process, which is in full development, is mainly fed by five streams (1,2, 3, 4 and 5).

The main compound for the synthesis process of high density polyethylene (HDPE) is Ethylene (C2H4), which enters through flow stream N ° 1 using Nitrogen (N2) as Inert Drainage Gas. Hydrogen (H2) flows through the same stream to control the molecular weight of the olefin. In flow stream No. 2, Hexane (C6H14), dehydrated high pressure, enters as a solvent to adjust the concentration of the reaction product in the form of pulp, and the comonomer 1-Butene flows through stream No. 3 (C4H8 - 1) for density adjustment.

Finally, the production of the process requires two types of catalysts: a catalyst called PZ that enters the reactor through Stream No. 4. Said compound is Titanium Tetrachloride (TiCl4) and the AT co-catalyst of a metallic organic composition called Triethyl Aluminum [AL (C2H5) 3]. Both catalysts are stored and prepared prior to each production cycle in the polymerization reactor.

The five flow streams previously brought up and detailed enter the reactor and develop an addition reaction in which the double bonds of the carbon atoms open and initially bind to the chlorine atoms of the PZ catalyst. These connections occur at the ends of the molecule in formation and then add AT co-catalyst atoms and form the HDPE paste.

The process also has centrifugal pumps with an isentropic efficiency of 0.7, in order to pressurize the lines of the fluids entering the reactor that require certain parameters to effectively develop their reaction.

Finally, the product of the reaction is subjected to a process of separation, drying, stabilization, extrusion and granulation for commercial purposes as previously mentioned. From here, this material is widely diversified in different processes of molding, blowing, injection and related to obtain consumer products and human utility applicable to the domestic industry, food, agriculture, security, automotive, oil, entertainment, construction , pharmaceutical, mechanical, among others.

I hope this article has been of great use appreciated readers of the community. For any additional input and observation I will be very attentive to your comments. I would greatly appreciate your support with your vote.

excelent post

Interesting POST, I'll definitely learn a lot of things with you!

Thanks, we are order @ejrangel