As I have described in my past post oil is a mixture of hydrocarbons that includes very light gases such as methane to semi-solid compounds such as paraffins and other more complex asphalt, all fuels; But while crude oil as such can be used as fuel, it needs to be processed in a refinery for different reasons. The main reason is that since crude oil is a mixture of many and different boiling points, the assembly as a whole can not satisfy the different applications, and certain fractions must be extracted, refined and modified using a variety of processes.

Isomerization is an important process in refineries, complements catalytic reforming and aims to transform n-paraffin into isoparaffins. Its importance lies in the transformation of nC4 and iC4 intended for alkylation to produce high octane numbers from light olefins by the addition of isobutane; or either to increase the octane number of the light products of the gasolines, such as fractions of C5 or C5-C6 of primary distillation of the crude or light naphtha of conversion processes, of low octane number.

ISOMERIZATION:

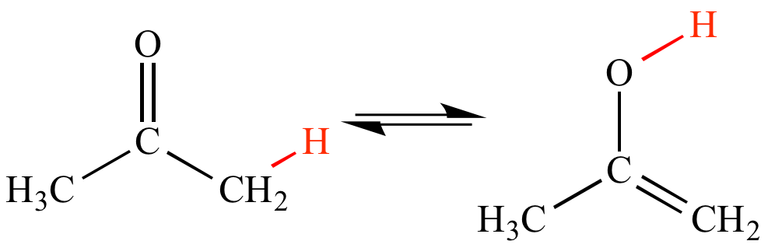

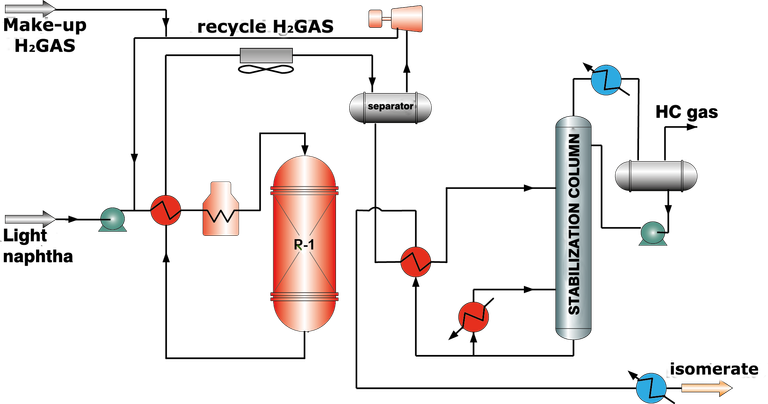

It is that chemical process by which a molecule is transformed into another that has the same atoms but arranged differently in terms of its geometric structure. Thus, it is said that the first molecule is an isomer of the second, and vice versa. In a refinery, isomerization complements the catalytic reforming, and aims to transform n-paraffins into iso-paraffins, either to prepare products required for transformations: n-C4 and i-C4, intended for alkylation; either to increase the octane number of the light products of the gasoline pool, such as the primary distillation fractions C5 or C5-C6 of crude oil or the light naphtha of conversion processes, of low octane number. It is a process of molecular rearrangement of linear paraffins of pentane and hexane (RON 60) that results in a naphtha (isomerate) (RON 82) of greater octane value.

The isomers differ in general in their chemical and physical properties. The isomers that interest in this process are those that have more favorable properties in terms of their use as fuels. In recent years the isomerization of light naphtha has acquired greater importance to meet the new specifications in gasoline, as it is one of the most attractive ways to reduce the benzene content.

Isomerization processes:

The Isomerization Unit is composed of two sections or processes:

1. Isomerization of the C4 or Butamer:

It is the catalytic process of isomerization of normal butane to isobutane in the presence of hydrogen, required as a raw material for an alkylation process to produce high octane gasoline.

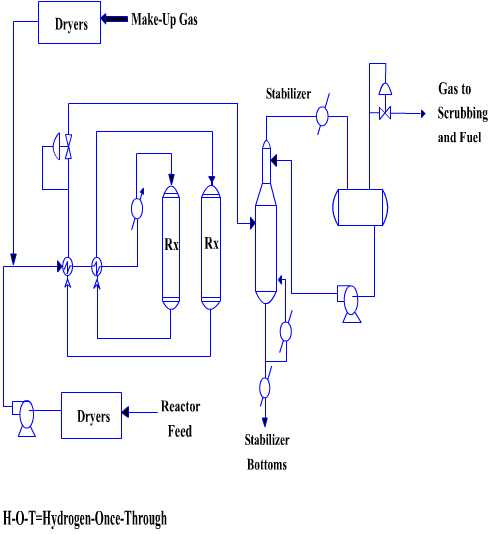

Food Section: In this process the feed used is butane.

Drying Section: The purpose of the dryers is to ensure that the feed has a minimum content of water, butane stream enters the bottom of the first dryer and flows through the bed of molecular sieves upstream to exit the top . Then, this current is sent to the bottom of the second dryer to exit through the stop towards the accumulator tank of the load. The dryers operate both in series, except when one of them is being regenerated and only one dryer is in service.

Reaction Section: Once the butane is dry, it is sent under flow control to the reaction section by means of the loading pumps to the reactors. The charge is mixed with the recycle gas stream, which basically consists of hydrogen, and passes through the cold charge exchanger, where it is heated with the effluent from the second reactor.

Hydrogen drying section: The purpose of these dryers is to ensure that the hydrogen in the unit is free of water. The stream of fresh hydrogen treated in the dryers is mixed with the recycle gas before being combined with the butane charge at the entrance of the first cold charge exchanger.

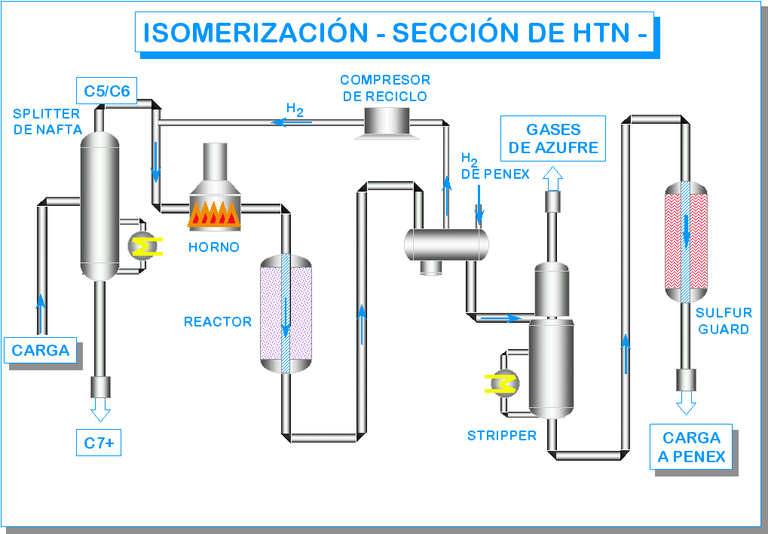

2. HTN (HYDROTRACTING OF NAFTAS):

The objective is to separate the pentanes and hexanes from the load, and then treat them with hydrogen to eliminate contaminants.

The section of HTN separates into a splitter the isomerizable cut of pentanes and hexanes of light naphtha on the upper part, and the cutting of heptanes and higher, not isomerizable on the lower part. The stream of pentanes and hexanes is brought into contact with hydrogen and brought to the temperature necessary for the reactions to take place, through a process furnace, before entering the reactor. In the reactor, the hydrotreating reactions are produced on a Cobalt-Molybdenum catalyst to eliminate the contaminants: metals, olefins, and sulfur and nitrogen compounds. The effluent enters a stripper to strip the sulfur gases produced in the reactor at the top; and from there it is treated in an absorbent bed, to eliminate any trace of Sulfur that it may still contain and finally be sent to the Penex section.

Importance of the isomerization of Butane and Pentane

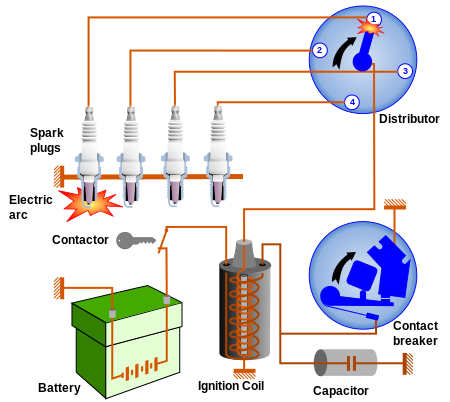

It constitutes the only possibility to increase the RON for the low-paraffin waxes, because the dehydrogenation constantly moves the system towards the aromatic hydrocarbons. Isomerization is of great importance in the improvement of combustible mixtures for internal combustion engines, known as naphthas. In the combustion engines of most automobiles, a mixture of vaporized naphtha and air is compressed and ignited at high temperature and pressure by means of the spark that the spark plug provides. For the engine to work properly it is necessary that the mixture does not burn spontaneously, before the precise moment, but causes the so-called pistoneo which causes loss of the efficiency of the engine and mechanical deterioration of its parts. Experimentally it is observed that, the more branched the hydrocarbon, it resists greater compression of the combustion chamber without igniting. For this reason, the isomerization process is very important in obtaining quality naphthas. This anti knock capability is measured on a scale called the Octane Index (RON).

For more information visit the following links.

Very good person very good news I happy to watch this

Hi, we have you blacklisted as a plagiarizer from some past posts. I you like, you can join me in steemit.chat and discuss the process in which you make a post and perhaps we can work something out (find me as @mobbs)

click here.Congratulations @frankjavier, this post is the fifth most rewarded post (based on pending payouts) in the last 12 hours written by a Newbie account holder (accounts that hold between 0.01 and 0.1 Mega Vests). The total number of posts by newbie account holders during this period was 2409 and the total pending payments to posts in this category was $1033.79. To see the full list of highest paid posts across all accounts categories,

If you do not wish to receive these messages in future, please reply stop to this comment.