Previously in my series on Reliability, I have explained the consequences of unreliability which at worst its death, frustration of users and loss of the equipment. Also I explained on how unreliability can tarnish the reputation of producers and make them loose value in the market, hence diminishing their essence of venturing which is actually to make profit.

In other to avoid all these consequences posed by unreliability, producers do everything possible taking cost as consideration to improve reliability. In the most recent episode on reliability, I have also explained the measures taken by manufacturers so as to increase reliability. However, I reserved maintainability(which is also a major of improving reliability) because it encompasses many branches which is better explained on this series so as to enhance understanding.

source:wikimedia||license:CCo 1.0 Public domain

Maintainability

Maintainability is the ability of an equipment to be restored into a state in which it can perform assuming fault or failure arises.In terms of class, maintainability can be classified into preventive and corrective maintenance. Each type of maintenance has its own merit and cons as rarely anything only advantages.

Preventive Maintenance

Preventive maintenance is a type of maintenance carried out on equipment beforefailure. This is done so as to minimize as low as possible the impending failures of electrical equipment.

Depending on industry and maintenance staff, preventive maintenance can be done annually or monthly.

The advantages of preventive maintenance includes

- Preventive maintenance prevents failure

- It Reduces cost and generates more revenue(in some systems the failure of one component gives rise to fault in the other, that is chain fault.. But if preventive maintenance is carried, the component that may give rise to chain fault would be changed before the chain fault occurs; hence saving cost)

- It reduces the need for standby equipment. If the reliability of the actual equipment in use is high, then there is low or no demand for a standby equipment.

- Preventive maintenance improves safety (the practical certainty that the usage of an equipment will not result to injury) which is of paramount importance in Engineering

Preventive maintenance also posses some disadvantages which are:

- Preventive maintenance might give rise to fault or entire failure of the system depending on the skill level on the maintenance staff. A maintenance staff who is careless might end up short circuiting two wires while trying to execute maintenance on an electronic appliance.

- Difficulty exists in ascertaining when the components of equipment will enter wear out period. Some components might enter wear out period few days of usage while some would enter wear out period after several years. So it is complex to determine the due time to carry out preventive maintenance

- It might not be economical to carry out preventive maintenance in some systems

Approaches To Preventive Maintenance

Some approaches to preventive maintenance exist which we will discuss below- Fixed Time Maintenance : This is an approach to preventive maintenance that is calendar/time based. In this approach, some components of a certain system might be changed every 6months or annually. This approach is choose when failure is time dependent. An example of time dependent failure is smart phone battery failure, some phone manufactures provides in the manual that phone's battery might loose capacity or wear out after 2 years

- Conditional Based Maintenance: This an approach to preventive maintenance based on current degrading condition of the component. The condition of the component can be detected using measuring instruments, monitoring equipment or by inspection based on human senses. Example of this is house(indoor) electrical system, one wire might be overheating/burning while power is stable, the human nose can perceive the smell of the burning wire, trace the direction, now find out the burning wire with the eyes and change it. It is still preventive maintenance since the ire is changed to avoid impending failure(a failure that has not occurred yet)

- Operate To Failure: This is an approach or kind of preventive maintenance that involves no replacement or new installing of the components of the system. A good example of operate to failure, is the lubrication of the moving parts of a machine. The machine has not failed, but its rotors are being lubricated which involves no component replacement

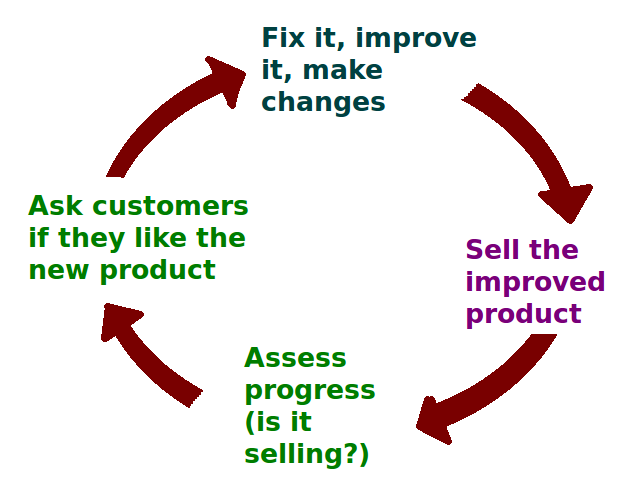

- Design Out Maintenance: This is an approach of maintenance based on fault or failure, that is to say that it depends on reliability data. Assuming an equipment keeps failing, the Engineers goes to the lab and design the system in such a way that it can overcome the actual failure encountered by similar systems.

- Planned Preventive Maintenance: This is an approach to preventive maintenance based on the past behavior of the system. Lets assume a system fails one in every 4 months, the responsible Engineers plan a preventive maintenance before every consecutive 4 months. Similar things also apply if the system fails weekly or annually.

This post has been voted on by the SteemSTEM curation team and voting trail. It is elligible for support from @curie.

If you appreciate the work we are doing, then consider supporting our witness stem.witness. Additional witness support to the curie witness would be appreciated as well.

For additional information please join us on the SteemSTEM discord and to get to know the rest of the community!

Thanks for having added @steemstem as a beneficiary to your post. This granted you a stronger support from SteemSTEM.

Thanks for having used the steemstem.io app. You got a stronger support!