The use of refractometry in various production processes has become increasingly necessary due to the requirements in current quality regulations, which include the entire production chain from the cultivation of raw materials, its reception and the preparation of final products in the chemical, agrifood and pharmaceutical industries, among others.

The determination of the refractive index (a fundamental physical property of any substance) is used, for example, to know the composition or purity of a sample, through an instrument called a refractometer.

Source

For this reason, the use of refractometers has gained great interest in the area of beverage manufacturing and a clear example is related to the production of wines. The presence of sugars is one of the fundamental parameters of the enology because this family of compounds intervenes practically in the whole process of elaboration that leads from the grape to the wine determining the quality of the final product.

Source

To know the concentration of sugars in natural musts is usually used to determine the refractive index, which is then transformed to a scale that determines the percentage by weight of sugars or total soluble solids, known as Brix degrees (° Bx). However, there are other scales such as Baumé degrees (° Be) and Oechsle degrees (° Oe) that also determine the concentration of these compounds in a sample and the relationship between the different scales is as follows:

1.8 ° Bx = 1 ° Be 0.2 ° Bx = 1 ° Oe

On the other hand, the two main fermentable sugars present in the vacuoles of the grains of grape are the glucose and the fructose

(that come from the enzymatic hydrolysis of the sucrose during the chlorophyll assimilation) and, during the maturation, the concentration of fructose is increased.

Source

In mature grains, the maximum concentrations of both sugars oscillate in the range of 150 and 350 g / L of juice, according to the strains; in this state, the glucose/fructose ratio is around 1 and 0.95, whereas in wine this ratio should decrease considerably and be between 0.2 and 0.4. To control this, it is necessary to measure and monitor the sugars throughout the fermentation process, generally in ° Brix or its corresponding in ° Baumé, calculating the glucose/fructose ratio by means of the equivalent of reducing sugars obtained from a comparison table. However, there are currently some digital instruments that are able to perform this conversion automatically.

In the food and beverage industry, refractometry has a broad spectrum of applications. Occasionally you can mention the products derived from fruits and vegetables, as for example, in canned fruits in syrup the so-called cut-out test is performed, to determine the homogeneity of a lot, measuring the percentage of solids total solubles (° Brix) in the supernatant liquid and the pulp. In the case of canned vegetables, the percentage of sodium chloride expressed in ° Be is determined (the Baumé degrees can also be equivalent in salt solutions being the ratio 1 ° Be = 1% of NaCl) in the brine and the vegetable in order to observe if after 48 hours the desired osmotic equilibrium has been reached, in addition to seeing if the net weight and the drained weight of the product is correct for the lot under analysis.

Another application of refractometry is seen in the preparation of marmalades, there are three fundamental parameters to obtain a quality product: acidity, sugar percentage, and concentration of the gelling agent, in this case, the final Brix degrees must be in the range of 55 - 70 ° Brix to maintain shelf life.

Source

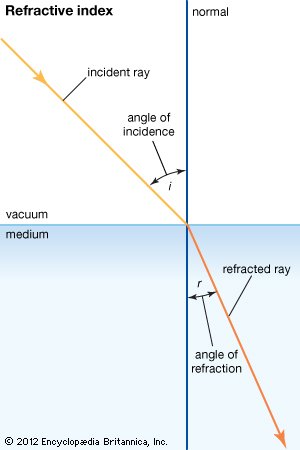

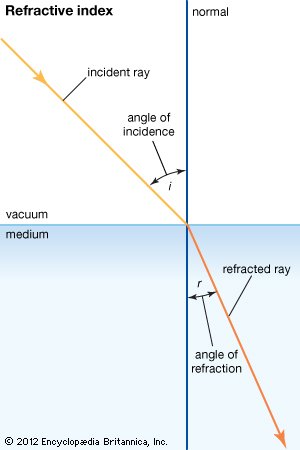

The working principle of a refractometer is based on the speed of light that depends on the medium in which it travels if a ray of light crosses slanted from one medium to another of different density, it changes its direction when it crosses the surface.

This change in direction is called refraction.

Therefore, when the light passes through a denser medium, the beam will approach the perpendicularity drawn on the dividing surface at the point of incidence. This phenomenon is mainly due to the fact that:

The speed of light changes, it becomes slower the denser the medium that passes through.

Source

In summary, refractometry has a wide range of applications in various industries so you should look for instruments capable of adjusting to the production processes in which you work.

References

- https://www.britannica.com/science/refractive-index

-https://en.wikipedia.org/wiki/Refractometer

-https://en.wikipedia.org/wiki/Brix

-https://en.wikipedia.org/wiki/Winemaking

-https://www.refractometer.eu/refractometers-food-industry-agriculture-crop-production

Great job!

Este es un servicio gratuito para nuevos usuarios de steemit, para apoyarlos y motivarlos a seguir generando contenido de valor para la comunidad.

<3 Este es un corazón, o un helado, tu eliges .Hola @jesusleal, upv0t3

: )

N0. R4ND0M:

4950 8602 7551 1434

4742 9985 9154 1422

1092 6663 9244 8600

9793 7336 7071 2784

Congratulations @jesusleal! You received a personal award!

Click here to view your Board

Do not miss the last post from @steemitboard:

Congratulations @jesusleal! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!