Hello, fellow chocolate lovers here on steeemit. I just want to share with you the processes involved in the production of chocolate. I believe that chocolate has health benefits such as the reduction of the risk of developing stroke and other heart-related problems, strengthening the human brain as well as preventing cancer.

Chocolate was first discovered by the Aztecs about 3100 years ago. They used it to make a beverage by pounding cocoa beans and adding spices and liquids. Montezuma believed it was an aphrodisiac and drank up to fifty goblets per day of this bitter concoction.

- Harvesting of ripe cocoa pods

The first step in the production of chocolate is the harvesting of ripe cocoa pods from the cocoa tree (Theobroma cacao). The time of harvest varies from region to region, but the process of turning it into chocolate begins immediately. The pods are cut open with machetes and the white pulp containing the cocoa beans is scooped out. Not all cocoa harvests are created equal. Everything from geography, to soil type to the climatic conditions of the harvest has a huge impact on the beans and the chocolate’s flavour profile.

- Fermentation of the cocoa beans

The pods and pulp are placed into large wooden containers, where the pulp is allowed to ferment for five to seven days. During the process, the beans are turned to help them ferment more evenly. This is the first stage in developing the flavour of the chocolate, and part of the reason why a farmer can have a direct impact on the quality of the finished chocolate.

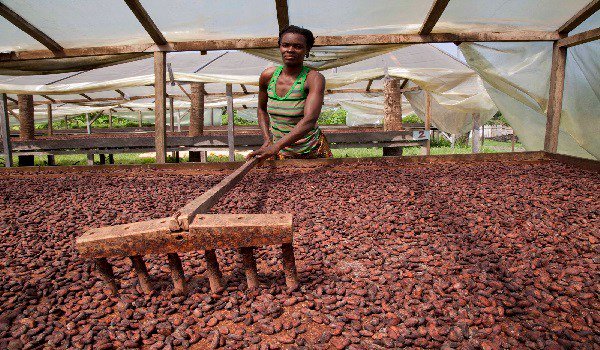

- Drying of fermented cocoa beans

After fermentation, the next step in the process is to dry the beans. This is usually done by spreading them out into a single layer in the sun. Most beans are transferred into sacks and transported around the world after drying, so in order to prevent mould, it’s important that they’re completely dry at this point.

- Roasting

The dried cocoa beans are then roasted by the chocolate maker to further develop the chocolate flavour.

- Cracking and Winnowing

The roasted cocoa beans have a thin, papery shell around them which needs to be removed, so at this point in the process, the beans are cracked open and the shell is removed in a process called winnowing. The lighter shells are blown away with fans, leaving behind pieces of pure cocoa bean, known as “nibs”.

- Grinding

The cracked cocoa beans are then grounded into a pasty form (cocoa mass).

- Kneading

Cocoa mass cocoa butter, sugar and flavouring are kneaded together to evenly distribute the ingredients and round the

flavour. This mixture is still gritty.

Depending on the kind of chocolate, different ingredients are used:

- Dark chocolate: Cocoa liquor + cocoa butter + sugar

- Milk chocolate: Cocoa liquor + cocoa butter + sugar + milk powder

- White chocolate: Cocoa butter + sugar + milk powder

Rolling

The paste is broken down into 10 to 20 microns.Conching

The paste is warmed to 80 degrees Celsius by internal friction brought about by intensive movement and strong shearing force and the mass liquefies. This process can last from 12 - 72 hours. The longer the conching the smoother the taste. This allows the bitter smells and flavours to subside and the desired aromas to fully develop. At the same time, the cocoa mass becomes completely homogenized and a fine film of cocoa butter surrounds each of the microscopic particles.

- Tempering

Great chocolate should have a shiny finish and a good “snap” – that clean clicking sound when you break a piece off. These are created by tempering, the controlled process of raising, lowering and raising the temperature of the chocolate to form exactly the right kind of crystals. If you were to let the untempered chocolate cool naturally, the chocolate would be soft and crumbly and would not melt evenly on the tongue.

- Moulding

The final step in making a finished chocolate bar is pouring it into a mould. The melted chocolate is simply poured into plastic bar-shaped moulds and agitated to remove any air bubbles. Larger chocolate makers will have machines and conveyors that deposit exactly the right amount of chocolate into each mould, but many smaller manufacturers still do this part by hand.

- Wrapping

Once cooled, the chocolate is wrapped up ready to be sent out. While some of the biggest makers have machines to help with this, most makers still wrap their bars completely by hand.

References

"Consumían olmecas chocolate hace 3000 años". El Universal (Mexico City) (newspaper). July 29, 2008.

Kerr, Justin. "Chocolate: A Mesoamerican Luxury 1200–1521 – Obtaining Cacao". Field Museum. Archived from the original on 7 July 2012. Retrieved 23 November 2011.

LaBau, Elizabeth. "How To Temper Chocolate". About.com. Archived from the original on 8 October 2008. Retrieved 20 May 2008.

This post has received a 0.21 % upvote from @drotto thanks to: @banjo.

chochoklat

Nice article! However, you might want to clarify if "cocoa mass" and "cocoa liquor" are the same thing.

Yes, they are the same

Thanks for this teaching

Charley ma moff make water water.

I wan chop chocolate rydee rydee

Hahaha