As a mechanical engineering student, when the word 3D Printing got through the ears and was processed by the brain, The only thought which ran through me was how this can change the world with just a little more focus on it most especially this part of the world, in fact, this is actually one of the major breakthroughs in engineering.

Come to think of it, every thing can be brought to actualization by a 3D Printer, you just have to ask the questions like can it be modeled, is the printing material in place, then you are a go.

3D Printing have changed the manufacturing industry, this did not only come with the reduction in human labor (speaking of human labor, robots were quite an achievement too), saving the cost of production and at reduced time, but also came with saving the planet in terms of pollution, such as noise pollution, harmful gases and and lots more, but today, we will be considering the big picture, WASTE MANAGEMENT.

On this article we will look at the concept of 3D printing and how it can play a major role in our world, with respect to waste management.

The Concept Of 3D Printing.

According to wikipedia

3D printing, also known as additive manufacturing (AM), refers to processes used to create a three-dimensional object in which material is joined or solidified under computer control to create an object, with material being added together (such as liquid molecules or powder grains being fused together)

That definition simply paints the picture of a manufaturing process which put to the trashcan the already existing manufacturing process wherby products are manufactured by the conventional selective removal process of which the lathe machine process is a good example.

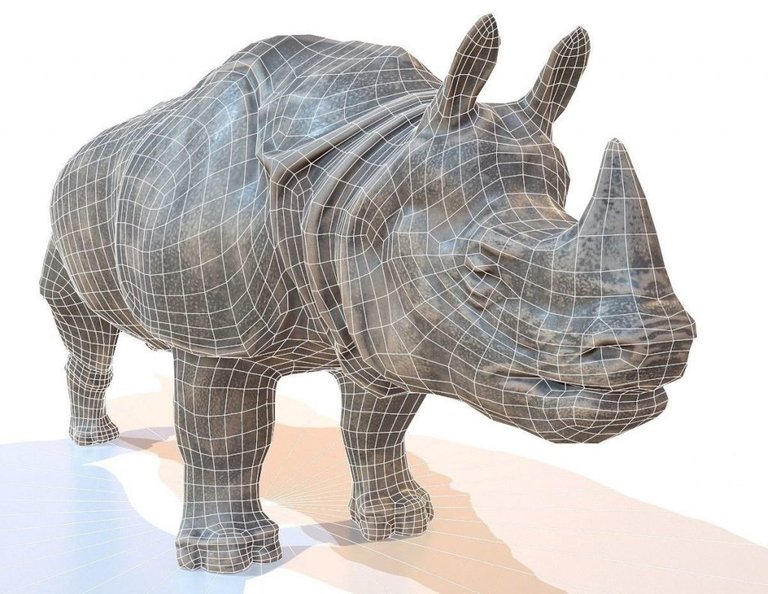

In This system of manufacturing almost any shape can be manufactured but this shape must be produced with the use of a digital modeled data which is also termed a 3D Model of the object to be 3D printed or another data source which is referred to as an Additive Manufacturing File (AMF) presented in sequential layers.

Was reading an article on the advancement in 3D Printing when i had a view of the first aircraft with 3D Printed parts which was cleared for flight as at March 2015 by the Fedral Avaition Administration , also came across a House printed with this technology just to mention a few, this simply implies that this technology of production have come to stay, and many all over the world embraced this, but the big question still remains, what is its impact generally on the industrial sector?.

3D printing technology is an easy approch to manufacturing, below is an overview of the 3D printing manufacturing process.

HOW 3D PRINTING WORKS

Model Design: 3D printing process starts with creating of a model with a computer which can be a CAD (Computer Aided Design) file. A 3D model can either be created from ground up with the use of a 3D modeling software or with data which can be generated by a 3D scanner(Creating a digital copy of an object)

3D softwares comes in different variants based on the niches, that is, there exist different softwares for different niches like the aerospace niche ,furniture design, fabric and fashion, engineering etc.

3D Printing

Slicing: Before the model can be printed by the machine, it will be prepared and this preparation process called Slicing. Slicing of a 3D model involves dividing a 3D model into hundreds or Thousand of horizontal layers. This can either be done by the design software or by a slicing software. When the model have been sliced, its now ready to be uploaded into the 3D Printer doing so, your object is ready to be printed layer by layer.

3D Printing: There exist several ways to 3D print, all these mentioned technologies are additive manufacturing processes but differ only in the ways the layers are built to create the object modeled. Some use the process of melting or softening materials being used to extrude layers, others cure a photo-reactive resin using an Ultraviolet laser (or similar power source) layer by layer.

Why 3D Print

Speed Of Production: This is one of the major advantages of additive manufacturing when compared to traditional manufacturing methods, it offers an increased speed at which parts can be produced. Complex designs can be uploaded into a printer in form of a CAD Design and printed just in few hours, hence a system with the ability to verify and develope design ideas more quickly when compared to the past process of manufacture which will take days or weeks to receive a prototype.

Single Step Manufacture:

One major concern of any manufacturer is how to manufacture parts more efficiently, manufacturing of most parts requires a number of manufacturing steps to be produced by conventional traditional manufacturing technologies and these diffrent steps tend to affect the quality and manufacturability of the design. 3D Printing complets a build in one step, i mean an opreation with no intaraction with the opreator on building and this gives the designer a greater control over the final product.

Risk mitigation: A faulty prototype will cost the designer time and money. Even a small change expirenced during fabrication may have a large financial impact, hence, with 3D printing there can be verification by printing a production ready prototype before investing in large manufacturing.

Complexity and design freedom: The layer by layer manufacturing process of 3D manufacturing makes possible for intricate parts with complex geometries to be printed with 3D Printing technologies.

Customization: 3D printing also allows for customization of design, this comes into play when parts are to be built one at a time with coustomized features, this have been applied in industries such as medical and dental industry.

Sustainability: Manufacturing processes which fall under the subtractive manufacturing such as CNC milling or turning makes use of removal of significant amount of material from a block which results to high volumes of waste but the additive process only make use of the material which is needed to build the part.

3D Printing And Waste Management

One Thing the 3D printing production system brought which i will refer to as huge is an oppurtunity to recycle waste materials and use them as materials for construction of products which can better serve the community.

PET Bottles

The 3D printer needs materials for its production process in a form of fillament structure, what better way to get these materials than from waste material through recycling, that sounds like killing two birds with a stone.

Waste management have been a serious issue when Africa and some other parts of the world is mentioned and this have not only taken a downturn on the enverionment alone but also to the good health of its inhabitants.

According to an article i read recently taged "a million bottles a munite" an estimation was done stating that a million PET bottles are bought every munites all around the world and this estimation is said to increase by 20% come year 2020 causing an environmental crisis, hence we as inhabitants of earth, as scicentists as engineers have to work with our sole objective to maintain our environment.

Imagine if those million PET bottles are gathered in a co-ordinated manner (say PET bottle collectors ) at coners of the road where individuals after consuming the contents of these bottles drop them in those boxes and they are gathered and transformed to fillaments which can be further used by the 3D printer for fabrication of rubber products, that's a nobrainer saving the world from this estimated hazard.

Africa most especially should jump at every chance of getting this waste out of the environment and that can only be a collective effort through sensitising the community on the need for waste management and putting things in play to convert these wastes into usable products by at least investing more in the manufacture of products using the 3D printing system of production.

The Future (Africa In Industrialization)

Though the 3D printing manufacturing process and other technological initiative have its negative impact to some section of the world which is yet to embrace technology at its fullest in solving problems, as this will lead to lack of jobs for the population and as this population increases it gets even worse, i still belive that we will just be doing the world a favour investing more in additive manufacturing.

We know that 3D printing of parts tend to reduce human involvement in the manufacturing system to an extent, but when weighed with its advantages, it will be better understood that industrilization will always be a key to community development.

Every advancement in science, technology and engineering have its effect on the economy, but will africa just sit back and watch the rest of the world progress just watching from a coner, i think that will be worse, rather we should try to keep up, if not with a fast pace, but taking a step at a time as we will be doing ourselves a huge favour going in that direction.

This article was inspired by an Engineering project to design and fabricate a machine which will crush PET bottles to filament to be used for 3D Printing hence forming useful materials from this waste.