In my last Steemit article, my dad asked me to print a drain cover because there were not any spare parts available or left in shops. This time my mom called me for some help and she had the same kind of problem. My mom owns a Moulinex grinding machine from the 70´th century and one of its very vital parts was broken. Naturally, the grinding machine is useless without that part.

It´s very interesting to follow how people are changing how they are thinking when counting problems. Nowadays most of the solutions are to print new or updated parts to cover old ones. I have to admit that my parents are nowadays a little bit more oriented to think about printing than my colleagues when they are thinking about problem-solving. I guess that's good and somehow a little bit surprising because my colleagues are cad designers.

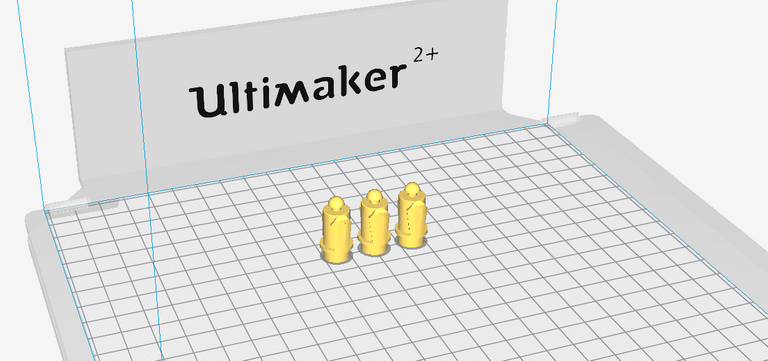

This time the printed part is holding the rotating blade. Original white holder was broken and gear wheel was not able to rotate to blade because this connection part was broken. The challenge in designing this new spare part was a small detail of gear wheel or rack. It was even hard to calculate the amount of those gears. After some time, I was able to copy all details of the holder and design these 40-years-old shapes into a digital format. I planned to print multiple spare parts at the same time to secure machine's working as I don't want to jeopardize my mom's' cooking.

The printing time for those three parts was 4h and I had to use the smallest nozzle to print the fine details. The size of the nozzle was 0.25 mm. The printing technology is an excellent way to give more lifetime to the old machines like this grinder, especially if it´s impossible to buy spare parts.

-Markos86

Awesome work! Your friends and family really appreciate your help. :)

Thank you!

True! Marko also helped us with his 3D-printing skills ;)

How long does the printing process take (from the very beginning to the last step)?

Join our Discord Channel to connect with us and nominate your own or somebody else's posts in our review channel.

Help us to reward you for making it ! Join our voting trail or delegate steem power to the community account.

Your post is also presented on the community website www.steemmakers.com where you can find other selected content.

If you like our work, please consider upvoting this comment to support the growth of our community. Thank you.

I would be interested in hearing how well it holds. There is alot of torque on that part. I assume they are printed solid?

It has worked well so far. Yes, it´s completely solid and the material is Ultimaker PLA.

Thats good to hear. The applicability of prints for everyday objects are still somewhat unexplored for me. I usually, make molds of mine and cast them in much more durable materials, so I havent really tested any of my prints IRL.

If it does break you could try reprint in ABS if you have, or nylon. You have the design now!

Saves all that plastic and metal going into a landfill.

Thats a great use for a 3d printer.

My wife has a hand held blender that is starting to slip, I am hoping to be able to tear it apart and give it a new lease on life soon too.

Thanks for sharing.

Congratulations @markos86! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOP