Total Gas and Chromatography

.jpg)

source

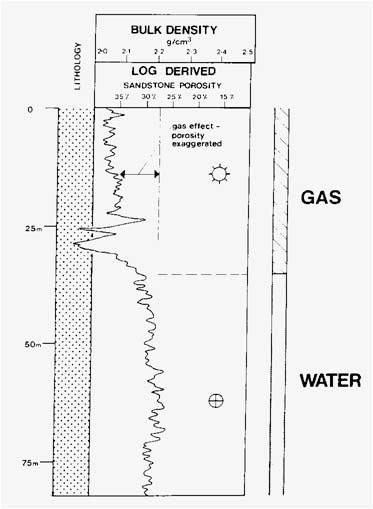

The main objective of the hydrocarbon registry is to determine the amount of gas contained in the sludge by releasing it mechanically by the action of the drill bit when drilling and cracking the formation. Assessing this way, the concentration of hydrocarbons in the formations traversed for commercial and safety purposes in people and facilities oil companies; being of great importance as an index of training pressures and content of hydrocarbons in the rock.

To continuously record the amount of hydrocarbon gases extracted from the sludge drilling, a degasser or gas trap placed in one of the cut boxes is used of the trembling; where the mud is stirred by some blades inside the trap to a constant speed, releasing the gas trapped in the mud to be absorbed and transported by means of a continuous flow hose to the recording unit where there is a total gas detector equipment containing a catalytic combustion chamber with filaments of platinum wire that are exposed to the mixture of air and gas extracted from the mud, and that be heated by a constant electric current and temperature, are capable of burning first wet gases at a temperature higher than 650 ° C, until reaching 890 ° C enough to burn the entire mixture of wet and dry gases.

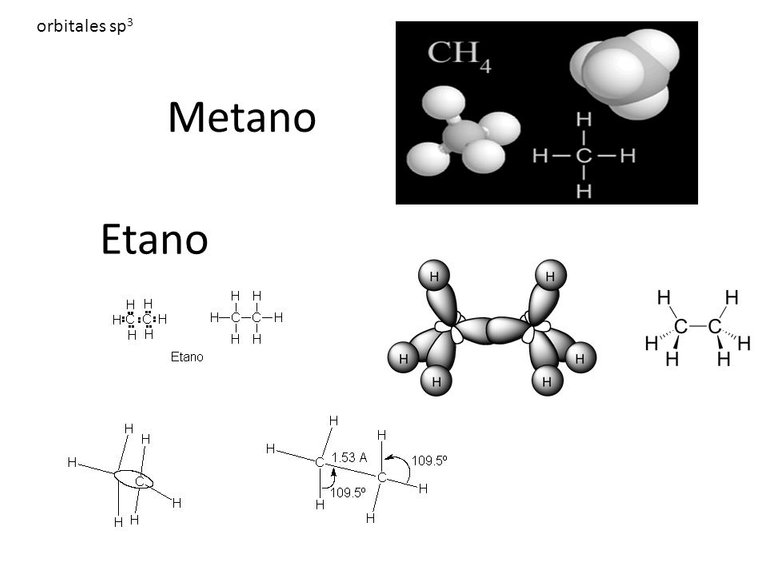

Through chromatography, a qualitative and quantitative gas diagnosis is made extracted from the drilling mud, providing a detailed analysis of all its components (methane, ethane, propane, isobutane, neobutane, isopentane and neopentane). The process of a chromatography or chromatogram consists of passing the gas mixture through a chromatograph (apparatus that contains inside a separation column where the gases are separated from according to the type of molecule). The first reading will belong to methane since it is the gas of minor molecular weight, the second to ethane and so on until completing the cycle. An analysis Continuous gas chromatography in the column of the hydrocarbon record chart provides one of the most valuable tools to interpret the value of a deposit with commercial content of gaseous and liquid hydrocarbons.

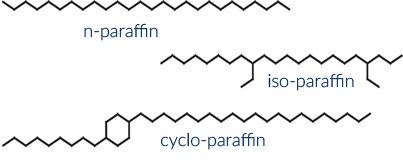

The series of hydrocarbons in the formation gases corresponds to the series of paraffin, which can be divided into four series:

* Normal paraffin:

Are all saturated hydrocarbons that have a chain structure straight. The simplest hydrocarbon is methane (C1H4) with a carbon atom surrounded by four hydrogen atoms; followed by ethane (C2H6), propane (C3H8), butane (C4H10), pentane (C5H12), etc. Of which methane of butane are gases. From pentane, hexane to Pentadecanes is liquid hydrocarbons that form the main constituents of the gasoline. And beyond these are solids, waxes, and eventually asphaltenes. The general formula for this group is Cn H2n + 2.

1. Iso-Paraffins:

They are also saturated hydrocarbons where some carbon atoms follow a different direction to the straight branches, forming a chain structure interlaced calls isomers of their corresponding straight chains with the same chemical composition and molecular weight, but with different physical properties and chemical The more carbon atoms there are, the longer the chain will be and they will form interlaced chains. The general formula is Cn H2n-2.

2. Cyclo-Paraffins or Naphthenes:

Are hydrocarbons whose carbon atoms they form ring structures with the hydrogens attached at their edges; its isomers are known as olefins. The general formula for this group is Cn H2n.

source

source

3. Benzene series:

Unsaturated or unsaturated hydrocarbons in structures of rings; also called aromatic for its odoriferous characteristics. They are present in all crude oils usually in small quantities. Benzene (C6H6) is the most common member and the general formula is Cn H2n-6.

The series of normal paraffin or paraffinic series is the one that includes most of the hydrocarbons contained in crude oils, so it is divided into two groups based on the gaseous components it contains:

a) Dry Gases represented by Methane and Ethane exclusively.

source

b) Humid Gases formed by other hydrocarbon gases of high molecular weight.

source

This classification provides the necessary information to define two types of demonstrations The first group indicates a manifestation of a production formation or gas carrier commonly called shale gas, which has no relation to the presence of oil in the formation. The second group indicates the presence of a gas demonstration coming from an area with oil, this being more important from the point of view commercial: the main objective of an oil well. It is understood as a manifestation of gas in the presence of hydrocarbon gas inside the mud when surfacing, altering the characteristics of drilling mud due to pollution, presenting high readings of gas and increase in mud volumes at the level of dams.

The classification of gas demonstrations is directly related to the good operations (drilling, circulation, short trip, bit change, etc.) so that you have the following types of gases.

source

a) Released gas, is the one that is in the pores of the rock and is incorporated in the mud as the auger is releasing it to crack the formation.

b) Gas produced is the one that is incorporated in the mud due to the pressure exerted by the pressure of the pores of the formation that exceeds the hydrostatic pressure and can come from any depth.

c) Gas recirculated or recycled (gas suction), is the gas that leaves the well in the column of the mud and that does not reach to be completely eliminated in the mud dams during a manifestation and is pumped back into the well.

d) Pollution gas is the one artificially produced in the sludge system of drilling by a source other than the formation gas (diesel, lubricants, oils, etc.)

e) Background gas is the amount of accumulated gas that remains static at the bottom of the well in the mud by a bit change, and that manifests itself after circulating time of delay. This gas is the product of the swabbing effect, decrease in density equivalent or for not having been formed in the last meters drilled in the good wall.

f) Connection gas is the amount of accumulated gas that manifests itself at the time of delay after connecting the drill pipe.

Finally, when in potentially exploitable bodies that due to density that has the drilling fluid or low permeability of the rock has not manifested in the gas readings in the mud, the gas is obtained from gas cuts through the crushing the sample of channel or core with the help of the blender, releasing the gas contained within the porous space of the rock or core cuts.

g) Gas cuts. When in rock bodies that are known to be potentially exploitable but that for reasons of the high density of mud that is being worked during drilling, or of the low permeability of the rock, no gas readings have been manifested in the mud when drilling In these areas of interest, gas detection is carried out in the rock cuttings that are recovered in trembling For this process, an auxiliary gas detector is used for the analysis. After recovering the cuts, these are placed in a blender filling the jar with water in half with a constant amount of all the analyzes. The jar is covered and the cuts from 30 to 60 are ground seconds depending on whether they are soft or compact formations. When grinding, the gas content inside the porous space of the cuts separates to form a mixture with the air that was left cover the jar of the blender, being extracted towards the interior of the detector releasing the gas of the rock, for the gas-air mixture pass through gas detector, where it will give us the corresponding reading.

source

For more information visit the following links.

- https://www.emerson.com/documents/automation/application-note-fundamentals-of-gas-chromatography-en-43550.pdf

- https://en.wikipedia.org/wiki/Gas_chromatography

- http://petrowiki.org/Hydrocarbon_analysis_during_mud_logging

- https://es.slideshare.net/Chrom_Solutions/total-gas-chromatography-workflow