Hello Steemians, I hope this meets you well. I'm glad to be back again. I've recently been engaged with my final clearance in school.

Very recently, I discussed how important Drying is in the agricultural storage process, and I promised to explain how certain dryers used in agriculture go about doing their job, this is coming late though, but like they say, it is better late than never. Actually, there are several types of these dryers, but I'll be focusing on three that are widely used. These three cut across the different categories of dryers. They are Solar Dryers, Rotary Dryers and Grain Bed Dryers. So if you're ready, let'move.

SOLAR DRYERS

I know I won't receive any medal for telling you that Solar dryers use energy from the sun to dry agricultural products, buy I just had to say it to satisfy that voice in my head. You may be more inclined to use a Solar dryer since we live in a world where the emphasis on green and renewable energy is a song that accompanies every breath we take.

Solar energy is as renewable as they come, needless to say, unlike some sources of energy, the source of solar energy will remain forever, and by forever I mean for as long as we live on this planet, since the source itself is fundamental to our very own existence on this planet. If you're also like me and you want to stay away from any sort of noise as much as possible, well this is what you should go for. Oh, and this almost escaped me, in my part of the world, Solar dryers are finding extensive application due to the unreliable and usually expensive electric power supply.

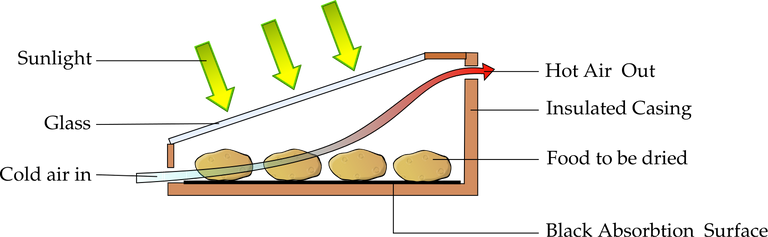

Now that the familiarisation visit is over, let's get over to the more intricate details of the Solar dryers. Firstly, they are majorly classed in two ways, you either call them Direct or Indirect. This classification is mainly based on how the heat from the sun reaches the materials to be dried. The former is used for Solar dryers that allow the products straight contact with the sun's heat, probably by just having a glass between the direct sunlight and the products to be dried.

The former however, prevents the products from coming in direct contact with the solar energy, instead it harnesses the energy with the use of a collector, which is then used to heat up fresh air for drying the products.

The Direct dryers are very easy to set up, as what you mainly need is a compartment to place the products to be dried, and then a transparent covering for the structure, which protects the products from contamination but at the same time allows the energy from the sun to reach them. The Indirect dryers though require much more to set up and I'll try to expatiate on that.

Very common to almost all types of Indirect Solar dryers are the following :

Collectors : This does the job of receiving solar energy from the sun and then channelling it to heat up the fresh air to be used for drying. Depending on its shape, you could call it a Flat plate collector or a Concentrator type collector. As the name hints, the flat plate directly collects and delivers the solar energy at various levels of low intensity, while the collector type is convex in shape, such that it converges the rays of the sun in a way that increases the intensity of the energy delivered (more like adding all the collected energy and making them a very big one) for heating the fresh air.

Air duct/Blower : The air duct is simply the space, usually the shape of a cuboid, where the heated air travels to reach the products in the drying chamber. However, for better and a more even circulation of hot air, blowers are used in some systems. Some solar dryers without blowers are designed with a slanting air duct to aid the movement of the heated air to the drying chamber.

Drying Chamber : The chamber has denied me the opportunity to define it, because the name is self explanatory. But that won't deter me from saying that the drying chamber is where the party takes place, the products to be dried are kept here and the heated air moves down here and does the work of drying the products right here. Some dryers have one big chamber for drying, while some others divide the chamber into shelves for easy holding of products.

Regulator : Without this component, the solar dryers will be nothing more than an hygienic upgrade of sundrying. This is because drying directly under the sun does not allow us to control the temperature and intensity of the heat, however with the help of regulators, Solar dryers are made in a way that the temperature inside the drying chamber can be regulated and controlled as required. Some systems install thermostats to switch the dryer off when the required temperature is exceeded.

ROTARY DRYERS

If you were to ask me the type of dryers I love the most, I won't hesitate to tell you this is it, very soon you'll see my main reason, but before we get to that, allow me to describe the rotary dryers to you.

These mainly find application in industries, so as much as I would love to tell you that you can make them on your own, the end will most likely not justify the means, because the cost efficiency is something that will be very low for household drying as the capacity you will be drying will be too low.

My first face to face encounter (asides theoretically learning about them in class) with rotary dryers came when I visited a factory that processes raw sesame seeds to the point of export, in case you're like me and you don't know what those seeds are upon first hearing them, they are those things sprinkled on top of your hamburger. In the same way, you will find them in many other food processing factories.

They got their name from how they move when in operation, they are cylindrical drums that usually have a long shaft running through them. The shaft is usually connected through an electric motor through a belt and pulley arrangement. As the electric motor rotates the shaft, the shaft also turns the drum, and the materials inside the drum too get turned, so much turning right? . But before you ask me if those numerous amounts of turning is what dries the products, NO is your answer. The next paragraph describes how they really get dried.

The drying is carried out with heated gas or air. The gas may be heated directly by a burner attached to the dryer, in which case it will be called directly heated or the air will have been preheated before being fed into the dryer, and in this case the dryer is said to be indirectly heated. An example of indirect heating is what I witnessed at that sesame factory, where they have an external boiler which supplies steam into their rotary dryers.

The air does the drying by moving through the rotating products, either from the same point where the products enter the dryer towards where they are discharged in a co-current flow rotary dryer or the heated air enters from the point where they are to be discharged and flows towards their entry point in a counter-current flow dryer. To know more about these flow processes, please check my previous post on drying processes.

In food processing companies, it is very important that the rotary dryers are made of Stainless Steel, as any other material that is prone to corrosion will lead to the contamination of the food products, and if this happens for a company, it means that whole batch if production will fail the Quality test. In fact, the processing plant will not be approved if the original inspectors properly do their job and find out that a food processing machine having contact with the food products is made of anything other than Stainless Steel.

Did you know?

Rotary dryers are constructed to slant towards the point of discharge, so that the products can be released under gravity.

Oh, I remember I said I will tell you why I love rotary dryers. You see rotary dryers are usually employed to do more than drying, they also carry out other processes while drying the products, like cleaning and separation. This of course will require that other equipment are attached to the dryer. For example, at the factory I mentioned earlier, some of the shafts of those dryers are fitted with rubber bars for brushing off the coat if the seeds, which of course is easier at this point because the temperature of the seeds would have been raised. Yet, this is not my main reason for loving these dryers.

My singular and ultimate reason for loving them actually is that most of the food processing companies can't properly function without these dryers, and I for one cannot function at all without abundant food, I mean my love for food is presently making me scour English dictionaries to find a better word to describe how I feel about food, because for me love doesn't even begin to describe it, ~~will you help me? ~~.

Now to the next and final one

GRAIN BED DRYER

If you are a lover of cereals, I can guarantee this is one of your knights not only in shining but radiant armour. I will say they are the least complicated of all three dryers we have touched. It is mainly used for grains, although some farmers use them to dry mixed animal feed.

The principle of operation is pretty straightforward. There is a bed, sometimes perforated, which is mounted upon a mesh of metals to hold it in place. This metal mesh is itself welded to the main frame of the Dryer. When seen, it appears like a cuboid tapering towards its end.

Of all the dryers mentioned, this is one I've actually been involved in its construction, about two years ago when I was on Industrial training. So I'll briefly run you through its fabrication and in the process explain how it works. Here are the fabricated parts.

The Frame : Usually made of angular iron bars and covered on the inside by Stainless Steel plates, and covered on the outside by mostly galvanized steel plates. However, it is of importance to note that the space between these two plates are packed with insulating materials like fiber to reduce heat loss from the dryer.

The Bed Support : This is an arrangement of bars welded to the frame around the mid-section of the frame from the front to the back of the dryer for the purpose of holding the bed in place, at such there is a space under the bed. They are usually made from varying metals (in some local workshops, cut-offs are used) in form of a big mesh.

The Bed : Since the grains are usually for food, Stainless Steel is used for this, depending on the grain to be dried and how, these sheets are sometimes perforated. They are welded in place to sit on the already prepared mesh (more like the way you place your bed on the ever welcoming frame).

The Heat Source : Depending on the financial capability of the farmer and the availability of different power source around, these can vary from gas to coal. If you remember the space thqtbis left beneath the bed, this is where the heat is passed to heat the bed and whatever has been spread on it. Some dryers are fitted with heat exchanger while some have blowers for proper circulation of the heated air.

Most dryers, no matter their type are packed with insulating materials in process called lagging to reduce heat losses.

CONCLUSION

My plan was to discuss at length as many agricultural dryers as possible, however that will mean I have to make a choice between saying so many things without being sure that any will be remembered and explain a little clearly enough to be sure of the audience's recollection, I suppose my choice is obvious.

For that reason I chose the three dryers due to their importance to agriculture as I've noticed in my country (Nigeria). The Solar dryer was chosen mainly because apart from the original investments it is the cheapest of the presently available options and it works quite well.

I've witnessed many farmers getting frustrated by either lack of electric power supply or the cost accrued just for the purpose of heating, with Solar dryers though, many have chosen to avoid unnecessary headaches.

However, so that you will not be completely taken away from the industrial world of agricultural drying, I decided to explain a little about the rotary dryers, their supplementary application and how they function.

The Grain Bed Dryer is also found on many local farm today, it has the advantage of drying more than just cereals, as earlier mentioned, it is used for feed, in fact I saw a pasture and range land expert who told me he used same for the drying of hay. More like saying that the old saying about hay and sun night as well be outdated, for with you bed dryer, you can sleep while the sun shines and successfully make your hay later.

With the foregoing, none of these is the best, you just need to see which one fits your product the best, which fits your present financial capability, so that you do not dry yourself out of business, and carefully select your best power source based on what is locally available (say solar in the tropics), and you are very good and ready to go drying.

REFERENCES

Norton, Brian (2013). Harnessing Solar Heat. Springer. ISBN 978-94-007-7275-5.

Shaffer, Marcella (1999). "Solar Food Drying". Backwoods Home Magazine. No. 58.

Trim, D. S. & Curran, C. A. (1983). "Solar dryers". Comparative Study of Solar and Sun Drying of Fish in Ecuator. London: Tropical Products Institute. ISBN 978-0-85954-158-9. .

Fodor, Eben (2006). "Build a Solar Food Dehydrator" (PDF). Mother Earth News. Vol. 2006 no. August/September. pp. 66–70.

Robishaw, Sue (1999). "Drying Food with the Sun". Countryside & Small Stock Journal. 1999 (July/August).

Weiss, Werner & Buchinger, Josef (2001). "Solar Drying" (PDF). Austrian Development Cooperation and Institute for Sustainable Technologies (AEE INTEC).

SOLAR DRYER| What is a Solar Dryer – Types, Applications & Construction| ROTARY DRYER

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

Hello! I find your post valuable for the wafrica community! Thanks for the great post! @wafrica is now following you! ALWAYs follow @wafrica and use the wafrica tag!

Thanks, I appreciate your recognition

Dryer ti wa online. 😂😂

Have you heard about freeze dryers?

This is a very good read, dryers are essential in food processes. Food is life.

Nicely written article Bro, keep it up.

Yes I'm familiar with freeze drying, I'll be discussing abut it and another new age method of drying in the near future, just you wait.

Thanks for always being here.

You are most welcome

Congratulations! Your post has been selected as a daily Steemit truffle! It is listed on rank 16 of all contributions awarded today. You can find the TOP DAILY TRUFFLE PICKS HERE.

I upvoted your contribution because to my mind your post is at least 18 SBD worth and should receive 112 votes. It's now up to the lovely Steemit community to make this come true.

I am

TrufflePig, an Artificial Intelligence Bot that helps minnows and content curators using Machine Learning. If you are curious how I select content, you can find an explanation here!Have a nice day and sincerely yours,

TrufflePigHi @sogless!

Your post was upvoted by utopian.io in cooperation with steemstem - supporting knowledge, innovation and technological advancement on the Steem Blockchain.

Contribute to Open Source with utopian.io

Learn how to contribute on our website and join the new open source economy.

Want to chat? Join the Utopian Community on Discord https://discord.gg/h52nFrV

wow

Sincerely I learnt alot from this post. I am glad to have stopped by. A well written post bro. But is there any hierarchy of these three forms of dryers. Or is there any one best used due to a particular reason?

The way technology runs is amazing. Life is made easy with these dryers. Personally for me, I'd go with the solar dryers since I don't have to pay for anything really. Nice piece bro.

I was lucky to have made use of direct sunlight in the construction of my solar incubator during my undergraduate thesis.. But there is this one i saw that was constructed just like mine except for the fact that this had blowers but it was a solar dryer... Looked just like the first image.. Is there any special name for that?